600X600mm Travertine Marble Floor Glazed Polished Honeycomb Core Tile

| Price: |

US $ 90-230/Square Meter |

| Min Order: |

50/Square Meter |

| Pay Type: |

L/C,T/T,Western Union,Paypal |

Product Specifications

| Thickness: |

8-100mm, Can Be Customized |

| Surface Treatment: |

Polished/ Antique/ Flamed/ Brushed |

| Weight: |

22kg/M2(15mm Thickness) |

| Performance: |

Lightweight,High Strenght,Anti-Vibration,Beautiful |

| Function: |

Decorative Honeycomb Panel |

| Aperture: |

6mm |

Product Description

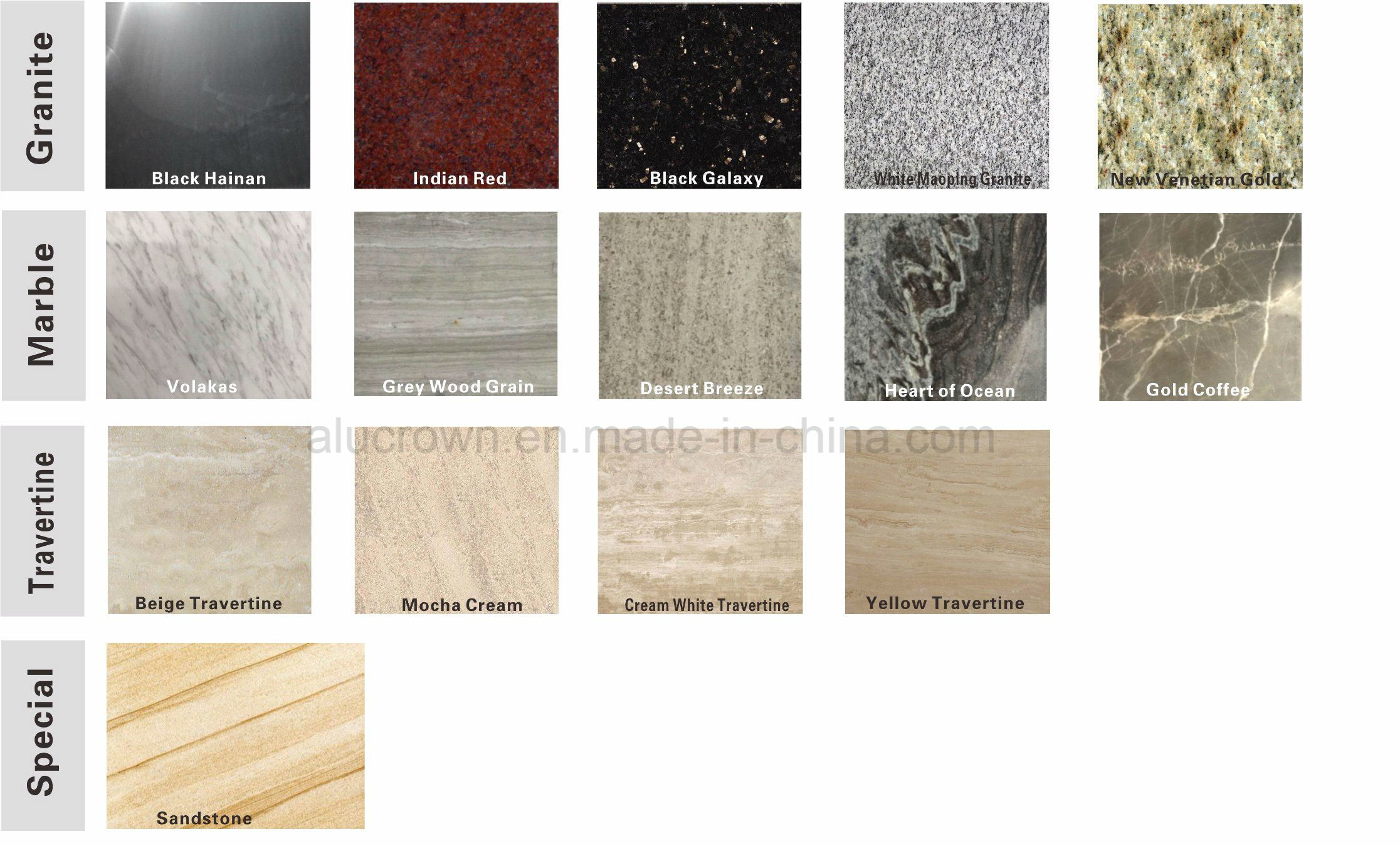

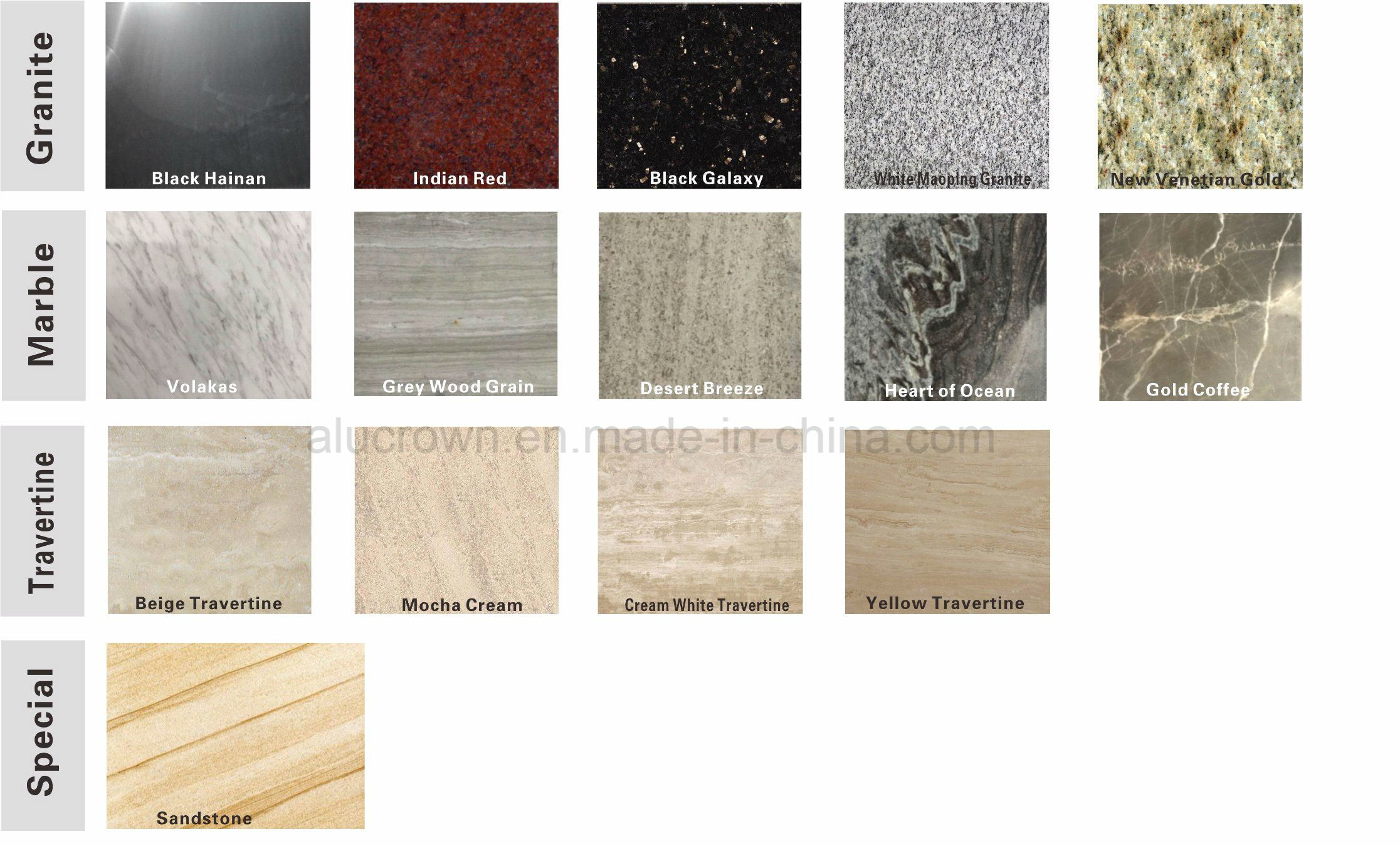

Alucrownstone is a fabricated stone panel wall cladding system utilizing a composite panel made by laminating a natural stone layer to an aluminum honeycomb panel with aviation grade epoxies. Alucrownstone is fabricated and then attached to the wall with a series of aluminum extrusions. Alucrownstone can feature a large range of natural stone finishes, including granite, marble, limestone and sandstone. The natural stone composite panels are suitable for interior and exterior use, being highly weatherproof and suitable for high impact areas.

TYPICAL specification| Item Description | Natural stone Aluminum honeycomb panel | Photo |

| Composite | Natural stone + Glue + Porcelain/aluminum honeycomb panel base |  |

| Stone type | Marble, Granite, Sandstone, Limestone ,etc |

| Stone Thickness | 3-5mm natural stone veneer |

| Total thickness | 8-100mm, can be customized |

| Surface | Polished/ antique/ flamed/ brushed |

| Standard size | 300*300mm, 300*600mm,600*600mm,600*900mm,1200*2400mm, other can be customized |

| Weight | 22kg/m2(15mm thickness) |

| Application | Building wall decoration, floor, table, ship, etc |

| Package | Protective film with foam and plywood crate |

Stone honeycomb panel specification

Face sheet: 3-10mm natural stone veneer

Total thickness:10-35mm

Maximum size:

marble honeycomb panel 1500*3000mm,

granite honeycomb panel 1200*2400mm

Granite:5.74 pounds/sq.ft (28kg/sq.m), 1/2 weight of 2cm granite slab

Marble: 5.33 pounds/sq.ft (26kg/sq.m), 1/2 weight of 2cm marble slab

Special size & shape: can be customized according to project's drawingFinish Option Disclaimer: Please note stone is a natural product. As a result, no two pieces are identical and may vary in markings, colour and texture. In some stones it is common to find spots, fossils or shelly formations, pit holes, open texture streaks, iron spots, and grain formation changes.TECHNICAL DATA

Disclaimer: Please note stone is a natural product. As a result, no two pieces are identical and may vary in markings, colour and texture. In some stones it is common to find spots, fossils or shelly formations, pit holes, open texture streaks, iron spots, and grain formation changes.TECHNICAL DATA| NO. | ITEM | STANDARD | TESTED VALUE | RESULT |

| 1 | Flat Bonding Strength | Average ≥ 1.0 MPa;

Minimum ≥ 0.6 MPa | Average 1.31 MPa;

Minimum 0.88 MPa | Pass |

| 2 | Flat Tensile Strength | ≥ 0.8 MPa | 0.91 MPa | Pass |

| 3 | Flat Tensile Modulus | ≥ 30 MPa | 70.7 MPa | Pass |

| 4 | Flat Shearing Strength | ≥ 0.5 MPa | 0.54 MPa | Pass |

| 5 | Flat Shearing Modulus | ≥ 4.0 MPa | 6.43 MPa | Pass |

| 6 | Bending Strength | ≥ 8.0 MPa | 41.0 MPa | Pass |

| 7 | Bending Rigidity | ≥ 1.0 x 10^9 N.mm^2 | 2.86 x 10^9 N.mm^2 | Pass |

| 8 | Shearing Rigidity | ≥ 1.0 x 10^5 N | 4.40 x 10^5 N | Pass |

| 9 | Climbing Drum Peel Strength | Average ≥ 50N.mm/mm;

Minimum ≥ 40N.mm/mm | Average 9.1N.mm/mm;

Minimum 42.4NN.mm/mm | Pass |

| 10 | Fasten Fitter Loading Capacity | ≥ 3.2 kN | 3.2 kN | Pass |

ADVANTAGESWhy use Crownstone over traditional solid stone??1,Lightweight-Crownstone is only 1/5 of the weight of its equivalent in traditional stone. This means that the product is much easier to handle and to ship, lessening damages, and improving onsite efficiency and safety.2,Simpls installation-Crownstone offers far improved attachment over traditional solid stone. The solid stone anchoring system exposes the weakest properties of the stone, whereas the fixing systems offered with Crownstone are rapid and align with common systems already used in Australia.3,Flexibility-Alucrown panels, using stone as a veneer over the honeycomb core are much flexible than dimensional stone. As a result the panels are much less prone to fracturing and cracking and better able to withstand building movement and extreme weather events.4,Stability-The thin stone found on Alucrown panels lack the torsional force the thicker traditional stone. This means the lightweight Alucrown systems doesn't experience the stability failure that occurs in traditional stone.FIXING SYSTEM

MANUFACTURING QUALITYA dedication to the total fulfillment of our client's and customer's expectations is reflected by a complete quality control system, beginning at the point of specification and continuing through to delivery of the guaranteed products. All activities are carried out in a manner which:1,Uses the framework of ISO9000 Quality Standards to verify the quality of our systems2,Ensures that our products and services are of the highest standards3,Creates continuous improvements to our product through the application of the best quality practices.WARRANTYThe standard warranty(Exterior wall) is 15 years.

MANUFACTURING QUALITYA dedication to the total fulfillment of our client's and customer's expectations is reflected by a complete quality control system, beginning at the point of specification and continuing through to delivery of the guaranteed products. All activities are carried out in a manner which:1,Uses the framework of ISO9000 Quality Standards to verify the quality of our systems2,Ensures that our products and services are of the highest standards3,Creates continuous improvements to our product through the application of the best quality practices.WARRANTYThe standard warranty(Exterior wall) is 15 years.

Package

Packing with protective film and plywood crate

Waiting for your more details of your project. More competitive price is waiting for you.

Foshan Alucrown Building Materials Co., Ltd is a professional engaged in the Chinese aluminum honeycomb panel series products: Curtain wall aluminum honeycomb panel, ultra-thin stone honeycomb panel, corrugated panel, enamel honeycomb panel and single aluminum panel series product development, production, sales of Foshan enterprises, Company covers an area of 3100, construction area of 2200.

Foshan Alucrown Building Materials Co., Ltd. Was established in 2015, is the first honeycomb panel manufacturers, rich experience of production of honeycomb panels, the owner of American Gurit CNC automatic spraying machine production line equipment. And has a set of 2 meters wide automatic continuous heat composite production line, multi - functional special-shaped thermal composite production line, aluminum honeycomb core production equipment. Advanced production equipment makes the company become the leading edge of the aluminum honeycomb board industry, to create first-class quality, capacity of 1000-3500 each day. Company's products have been awarded: Honorary title awarded by the China Building Materials Circulation Association awarded "creditable quality of construction project and to promote the application of new product certificate", the Ministry of construction science and technology information research, "building materials scientific and technological achievements popularization and application of the project (product) certificate, China building installed metal building decoration Association Committee issued a" fixed scientific and technological development, the certificate of production base and China Quality of service excellence. Company has passed GB / T19001-2000idt, S09001: 2000 quality management system certification, the company adopted the standard to improve the existing quality management system, to implement, maintain, and continue to improve the effectiveness of the system.

The company has always attached great importance to product quality and market demand, in the production and operation of the "first - class enterprises, a first-class reputation, first-class products, first-class service" quality policy. To further create new advantages, expand the market and to help your products to lighter, stronger, more straight, better performance, lower cost, Granville company may, in order to ensure the reliable quality, the attitude of sincere cooperation, for you to provide first-class services.