Product Specifications

| Prod Model: |

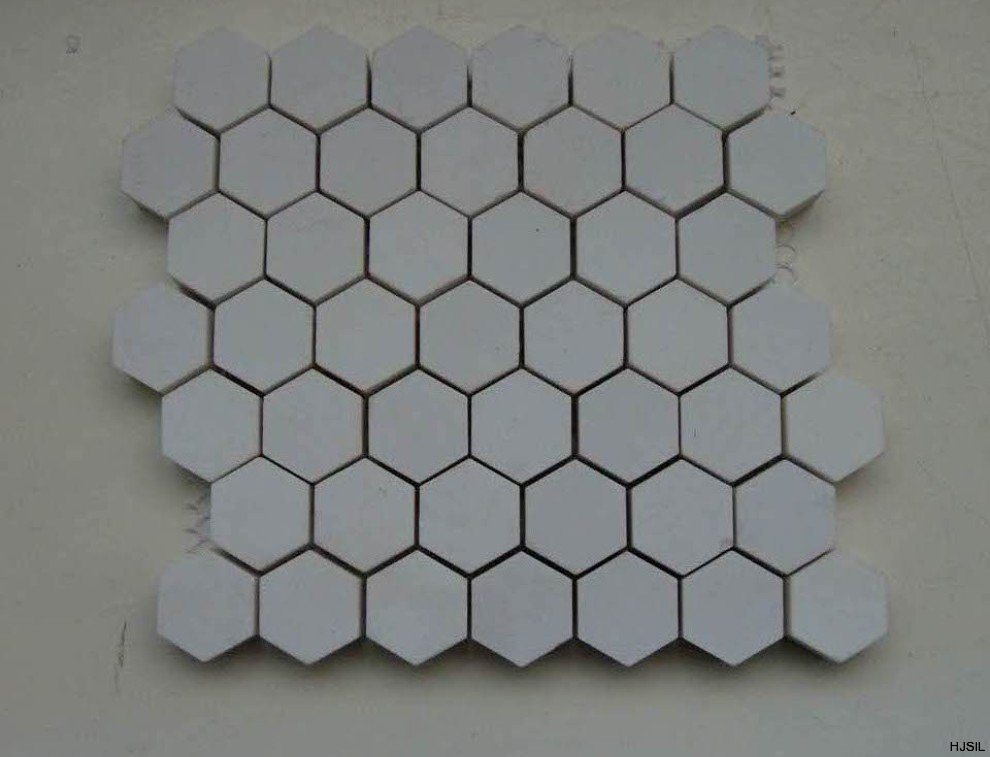

Mosaic tiles |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| 12mm Side Length: |

12 Thickness |

| 92% Alumina: |

Mosaic Tiles |

Product Description

Wear-resistant Alumina Tile

Characteristics:

Wear-resistant Alumina Tile with high wear resistance, acid and alkli resistance is effectively prolong the service life of equipment and considered to be the best choice of anti-wear and anti-corrosion material; The products are ideal wear-resistant surface materials for transfer equipments in mineral, steel and power industry.

Application:

1,Ceramic complex pipeline of glass fiber reinforced plastics

2,Alumina ceramic liner for cement cyclone

3,Metal complex pipeline and elbow

4,Wear-resistant liner for down spouting

5,Wear-resistant liner for pipeline

6,Preheater bracket

Why choose ZALY?

- Professional manufacturer.

- Guaranteed quality. Our production process conforms strictly to the requirements of ISO9001 quality management system. Quality inspection is carried out in every links of our production. SGS third party inspection is available.

- Sound after sales service. We provide sound after sales service. We provide 24 hours' consultation service. We are ready to answer your consultations at any time.

- Free sample available

|

Items/Data |

SS-AWT-92 |

SS-AWT-95 |

|

Al2O3 (%) |

≥92 |

≥95 |

|

Hardness(Mohs) |

9 |

9 |

|

Water Absorption (%) |

≤0.02 |

≤0.02 |

|

Fracture Toughness (MPa) |

3.65 |

3.75 |

|

Bending Strength (MPa) |

255 |

275 |

|

Density(g/cm3) |

≥3.60 |

≥3.65 |

Lianyungang Zhong Ao Aluminium Co. Ltd (AIZA)

Our Products:

Alumina Ceramic Ball

Alumina Ceramic Lining

Alumina Ceramic Cylinder

Alumina Wear Tile

Alumina Ceramic Beads

Alumina Ceramic Nozzle

Alumina Ceramic Ring

Insulation Ceramic

Customized Heterotypic Technical Ceramics

AIZA is a Lianyungang based Sino-Foreign joint venture corporation. It is a Chinese producer of calcined alumina and a manufacturer of alumina ceramics, such as alumina ceramic ball, alumina ceramic cylinder, alumina wear tile, ceramic insulator, ceramic element, ceramic beads, and other insulation ceramics with self-prepared material as well as German and Japanese material.

Since its creation, AIZA has served most of Chinese customers, Nanjing Huade, Zhuzhou Xianghuoju, and Chaozhou Sanhuan, which are eminent manufacturer of spark plug and advanced ceramic in China. Its "TCH" brand calcined alumina is well accepted by our customers.

In 2008, AIZA purchased 70 key equipment from Shanghai Morgan Matroc after its closure in China. The equipment includes isostatic press machine, dry press machine, hot press cast machine, ball mill, alumina spray prilling tower (centrifugal and pressure), polishing machine, etc. The equipment has been successfully installed in our factory by the end of 2008. Now, AIZA have succeeded in establishing itself as sole Chinese manufacturer of ceramic nozzle by isostatic dry bag pressing process. Besides, the most experienced technical engineer of former Shanghai Morgan Matroc also joined us, which is the precious source of our confidence of ensuring products quality.

TQC Procedures and ISO 9001: 2000- Certification

Our experienced QC will supervise the production and check the quality before delivery. We conduct TQC procedures according to ISO 9001: 2000-certified guidelines. In order to ensure better quality, we carry out five processes below:

1. Material inspection

2. Semi-manufactured goods inspection

3. Itinerary inspection

4. Finished products inspection

5. Shipment inspection.

Material Adopted:

Alumina

Zirconia

Steatite

Alumina-Zirconia

Technologies Adopted:

Dry Pressing

Isostatic Pressing

Heat Press Cast

Flowchart of Customized Service: Drawing Received---Researching and Tooling---Sample Collecting and Testing---Sample Accepted---Order Confirming.