Product Specifications

| Feature: |

Breathable, Bendable, Fire Retardant and |

| Certification: |

SGS, The National Fire Protection a |

| Delivery Detail: |

Within 7-20 Days Upon Receipt of Whole Payment |

| MOQ: |

500 PCS |

| Customized: |

Customized |

| Material: |

PE/ PVC/ Aluminum |

| Type: |

Fireproof Artificial Thatch |

| Shape: |

Same as Nature Thatch Roof |

| Size: |

1000*600mm 500*460mm 230*460mm |

| Color: |

Nature Thatch Color, Mix Color |

Product Description

China Artisan Synthetic thatch, aritifical thatchSynthetic thatched roof

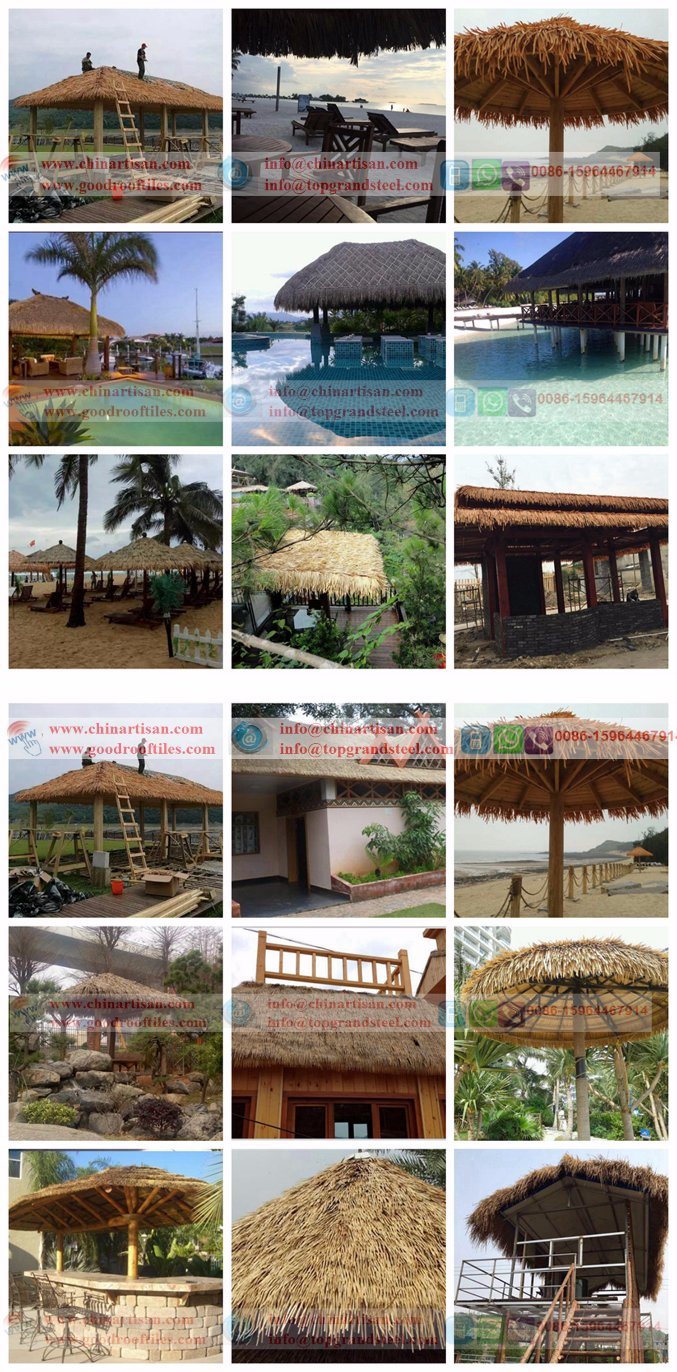

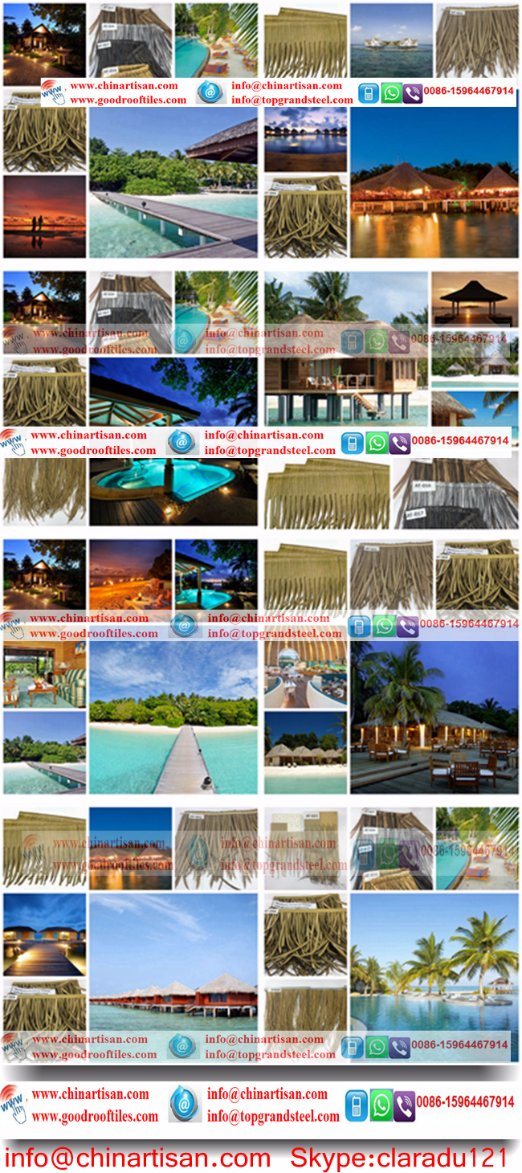

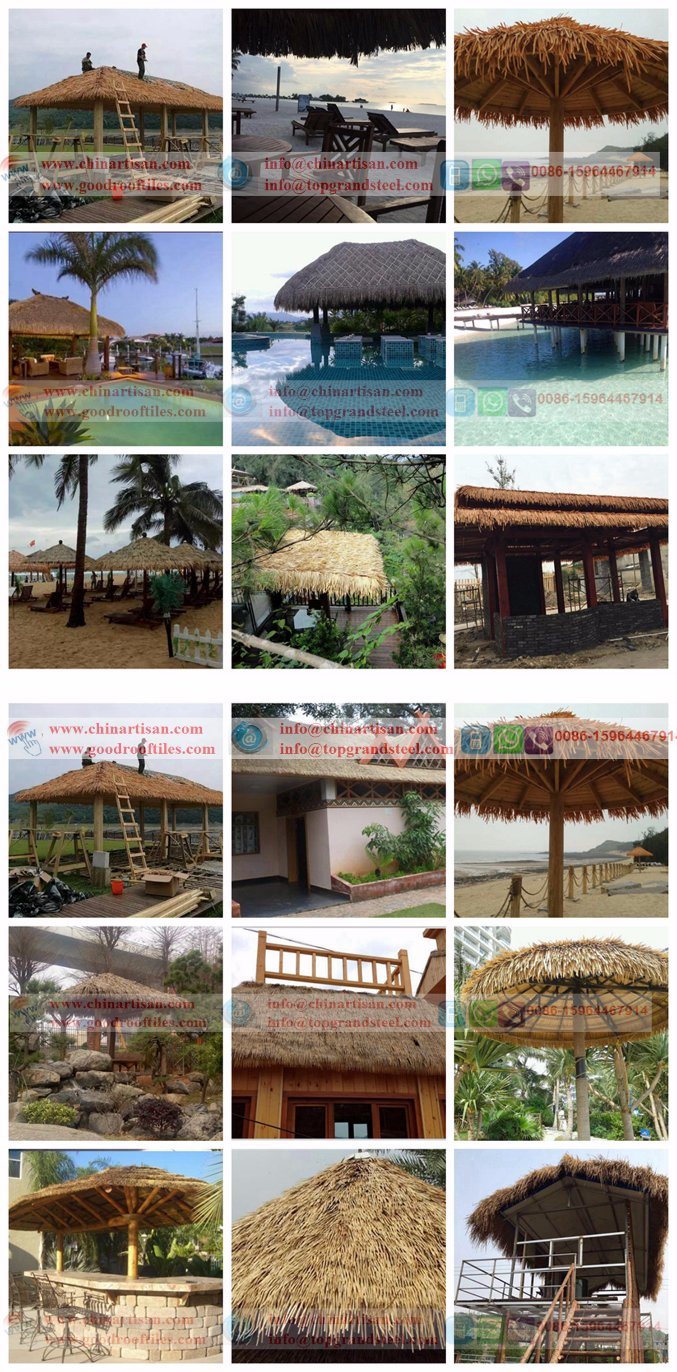

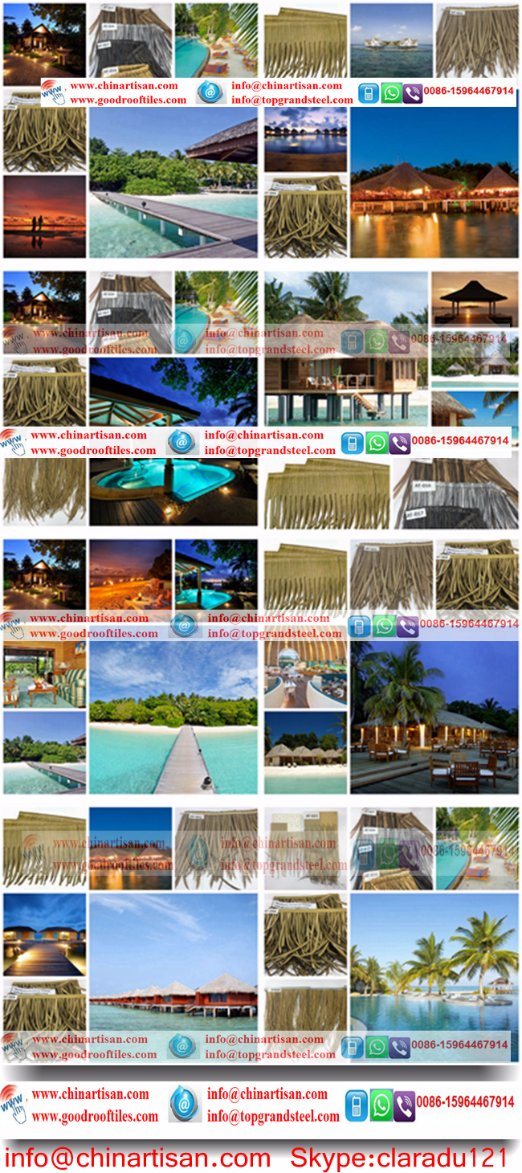

Thatched Umbrella

Tiki Bar/Tiki Hut1.0 Product Description/Thatch Overview Our synthetic thatch is made of PVC and PE, is a new landscape ideal material for roof decoration. It can be used for holiday, resorts, promenades, beer gardens, beach front hotels, side-walk cafes, restaurants, swimming pools, etc. Its natural decorative defection will bring you back to the nature relax your mood.

1.2 Features

1. Synthetic Thatch is resistant to wind and sun and rain, protozoa, fungi, rot, rust

2. 100% simulation to real straw or thatch

3. Never decay, shed or mold, life expectance up to 30~50 years

4. Installation is simple, free from influence of various roof shapes, wide range of applications

1.3 Different Types

We have more than 20 different styles of Synthetic thatch,

In Order to meet our customer's new requirements, special Products can be Customized.

2.Thatch Application & Our Projects

Hotels in the Garden District, the zoo, theme parks, restaurants or bars in the outdoor pavilion, landscape,Spa resorts, parks and scenery, resorts, bus stations, recreation pavilion, high-end residential buildings, villas District, museums, seaside bars, beach grill bar, water sports pavilion, tropical-style venues and so on.

3. Installation Method

Installation catalogue & videos 4. Production Line & Packing & Loading

Quanlity Details of 20'/40' Container as below(after pics) Specification of Synthetic Thatch

Specification of Synthetic Thatch| Material | Specification(L*W*T) | Pcs per | N.W | Quantity for | Quantity for | Fire Rating |

| sq.m | (kg/pc) | 20 Ft.Container | 40 Ft.Container |

| | | (pc) | (pc) |

| PE | 250mm*460mm*6mm | 12 | 0.5 | 20736 | 43200 | Non-flame resistant |

| 500mm*460mm*6mm | 6 | 1 | 10368 | 21600 |

| PVC | 250mm*460mm*6mm | 12 | 0.5 | 20736 | 43200 | V0 flame retardant grade |

| 500mm*460mm*6mm | 6 | 1 | 10368 | 21600 |

| Nano-Modifield | 250mm*460mm*6mm | 12 | 0.5 | 20736 | 43200 | V0 flame retardant grade |

| HDPE Material | 500mm*460mm*6mm | 6 | 1 | 10368 | 21600 |

5.FAQ 1.Q:You are factory or trading Company? A: We are a Factory with 8 years of experience specialized in cold rolled coil, galvanized steel coil, ppgi and corrugated roof sheet with high quality, competitive price and good service. 2. Q:what is the MOQ.? A:Generally speaking, the MOQ is 500 SQM, if your quantity is small , we can supply you from our stock . 3.Q: I need sample, could you support? A: We can supply you with the sample for free, but the delivery charges will be covered by our customers. For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for Freight Collect. Also you can have a visit to us, welcome to JNC!

4.Q: How to know the Quality Guarantee: A:We suggest you to visit our company to check the quality. And also the third inspection can prove our products quality.

B :We will attach some relevant photos via email to show our office and products to you. 8. More Views 5.Q: The Payment and Delivery item

5.Q: The Payment and Delivery item| 17 | Product feature | Fire resistance,light weight,easy installation,aesthetic,high tensile |

| 18 | Packing | with Carton for Synthetic Thatch |

| 19 | Weight/ Pc | 0.35-0.65 kgs |

| 20 | Qualification | ISO9001-2000Certificate, SGS. BV |

| | More information of Synthetic Thatch |

| 21 | Payment Term | T/T or L/C (We usually charge 30% of the deposit first.) |

| 22 | Trade Terms | EXW,FOB, CFR ,CIF,DDU,DDP,DAP |

| 23 | Delivery Port | Qingdao Port or Tianjin Port or Shanghai Port |

| 24 | Delivery Time | Within 20 days after receipt of T/T or L/C |

| 25 | MOQ | 1000 Pcs |

| 26 | Application | Spa resorts, parks and scenery, resorts, bus stations, recreation pavilion, high-end residential buildings, villas District, museums, seaside bars, beach grill bar, water sports pavilion, tropical-style venues and so on. |

| 27 | Ambition | Reliable product, Competitive price, On-time delivery and High standard service. |

6. Why choose us?1).Advantages: We have two production line of making Synthetic thatch, total week output is about 50000 SQM. Also we have professional salesperson from three international sales department, a group of technical engineers And skillful quality control inspector.

2). Special technology support: In Order to meet our customers new requirements, We also can manufacture the special Products, 3). Conform the international quality standard: All products for export, according to the

International quality standard of Europe, Japan, Russia and America to produce.7.CONTACT US Grand Industrial (China) Co., LtdAdd:Zibo City, Shan dong Province, China

Tel:+86-533-3121821

Fax:+86-533-3121821

Mobil:+86-15964467914

Web:www.goodrooftiles.Com

Web:www.topgrandsteel.com

Established in 1998, Grand Industrial Co., Ltd is deeply ingrained in Zibo (Shangdong Province, China). Our annual turnover is US$ 10, 00, 000 to US$ 60, 00, 000. Our major markets are North America, Eastern Asia, Southeast Asia, Middle East, Africa and various others.

A Brief History

In the past 16 years, we have been offering quality products to our valued customers. Our range includes prime steel, CR/GI/ PPGI Coils & sheets, new material roof sheets, sandwich panels, H beam channel, C/Z steel, steel villa, steel structures, etc. Till now, we have 200 employees and four workshops. Our products have covered main global markets such as Africa, North America, South America and Middle East. Our markets spread to over more than 20 countries and regions.

Our Manufacturing Unit

Our steel structures, building and resorts decoration materials are carefully fabricated in our state-of-the-art manufacturing unit using the latest machines. Owing to the strategy of industrial centralization, our factory is located at the center of steel building material production base and thus, ensures consistent product quality along with low price and constant availability. Our unit is equipped with a full set of equipment such as highly speed rolling, die-cut, material recycling, heat incision, heat combination and corrugated machines.

Quality Assurance

We have our own QC staff that includes seven persons in chemical department and eleven persons in machinery department. Our QC department strictly checks the quality of the products at every production level. Our staff visits the factory directly and takes random samples, which are further compared to the quality standards. Our professional engineer can also set the machine on site, if required. We can also apply for the third party inspection for our clients on special requests.