Product Specifications

| Prod Model: |

autoclave |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Guarantee: |

1year |

| Diameter: |

500-4500mm |

| Raising Pressure Speed: |

0.1MPa/Min |

| Temperature: |

150-450 Degree |

| Design Pressure: |

0.5-5.0MPa |

| Length: |

1000-20000m |

| Point Temperature Difference: |

+_1.2 Deg |

| Type: |

Insulating Glass Production Line |

| Certification: |

ISO |

| Control System: |

PLC |

Product Description

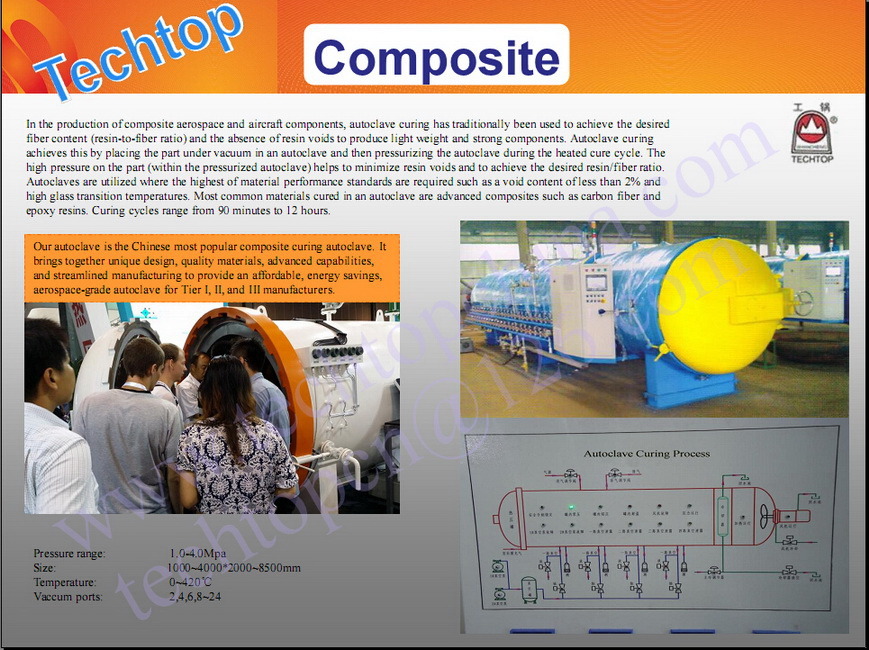

Our autoclave represents the highest technical level in China & In world, we have many top customers in China and in world , for example, AVIC,Nuclear Industry Research Institute,Special Material and Technology Research Institute and Zhongnan University Laboratory.

Autoclave is the key equipment of the laminated glass production , it can bond laminated glass firmly together through heat, pressure, cooling process,The equipment is composed of heating, cooling system and after insulation of the autoclave body and control system.

The autoclave can be customized by your requirements

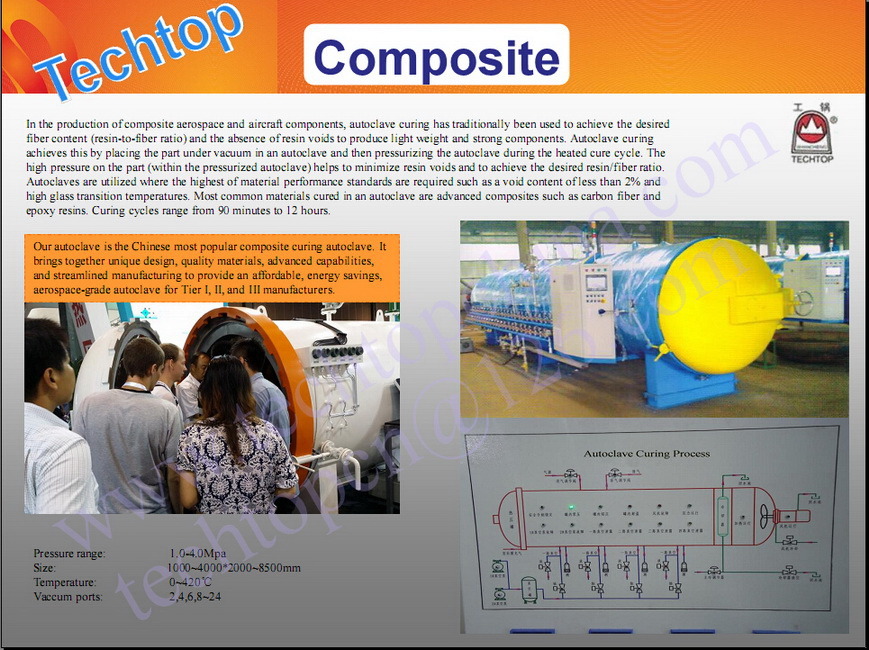

Autoclave can realize temperature ,pressure ,cooling and process parameters timing ,real-time on line controlled equipment .Mainly device into below systems:

1. tightness of tank :it is made from tank ,tank door ,high temperature motor ,air duct heat partition layer to form into one high pressure resistant ,high temperature tank

2. safety interlock : it is made from pressure automatic interlock ,manual interlock ,over pressure alarm device.

3. Quickly open door device :manual or automatic quickly open design ,even If power off ,it can start and close the door

4. Sealing device: the door adopt silica gel filling air ,it can bear 500 degree ,forming into one high temperature high pressure sealed container

5. Pressure system: pressure transfer and control system include air compressor ,storage tank ,pressure control valve ,pipe ,pressure transformer ,and pressure gauge .

6. Heating system: stainless steel heating pipe ,high temperature fan ,wind plate ,insulation layer ,temperature control system .heating power satisfy with inside tank max temperature requirement and raising temperature

7. Temperature circulation system :it made up of circulation fan ,wind plate ,and guide flow cover to improve heating transfer and circulation form into uniform temperature

8. Vacuum system :it made up of vacuum pump ,pipe ,vacuum gauge ,vacuum vale ,to supply composite material vacuum condition

9. Automatic control system: adopt PLD and fuzzy control ,to realize the pressure ,temperature ,cooling and so on full process high -precision control and in time record

Main technology date :

Item | date |

| Effective diameter | 500-5000mm |

| Effective length | 1000-40000mm |

| Working temperature | 100-450 degree |

| Working pressure | 0.5-5.0Mpa |

| Raising temperation speed | 0.1Mpa/min continuous adjustment |

| Temperature go down speed | + 0.01Mpa

- |

| Cooling ways | 0.5-7 degree/min continuous adjustment |

| Point difference temperature | 0.5-7 degree/min continuous adjustment |

| Control temperature and test temperature point | Water cool and wind cool |

| Vacuum degree of cavity | -0.098Mpa (absolutely pressure ) |

| Extra vacuum pipe | Extract 2-20 pipe extract and test is independent |

| Test vacuum pipe | Test 2-20 pipe extract and test is independent |

TAIAN TECHTOP INDUSTRIES Co., Ltd is established and authorized the only exporter by "Shancheng Boiler Co., Ltd", in charge of "SHANCHENG" products oversea market. We have excellent quality, professional technical team, mature operational model, perfect pre-sales-sale-after sale oversea market service system. Our products have been sold to India, Pakistan, South Korea, Vietnam, Thailand, Indonesia, Bangladesh, Croatia, Mexico, Namibia, Iraq, Libya and other countries, etc.

Mother company "SHANCHENG BOILER Co., Ltd" is a Comprehensive Enterprise include design, manufacture, detection, installation, anti-corrosion, heat preservation and market of energy equipments and pressure vessel. We have eight subsidiary companies: Shancheng boiler factory, Techtop Industries (Market), Mingjiang factory (vessel manufacturer), Huaneng Installation factory, Xingxing Boiler Accessory factory, Jinhgzhonghuanbao(environment protection and accessories), Xinwei factory (Auto radiator), Jingwei Network.

All the products detail pls see our website: Www. Techtopchina. COM.

Mainly products: Steam boiler, hot water boilers, coal fired, oil fired, gas fired boilers, biomass boilers; Thermal oil boiler, power plant boiler, etc and accessories. Pressure Vessel, LNG/CNG chemicals storage and transport equipments, autoclave, stainless steel equipments, auto radiator, heat exchanger, generator set. All these products are energy-saving, and are acknowledged by National Bureau of Quality Inspection and Quarantine.

"Endless innovation, flawless quality" is always the operation philosophy we seek, Our company based on the principle of "quality first, profit second", and we also insisted on the service concept of taking market as guidance indeed, taking customers as god sincerely.

We will develop side by side with all of our customers!

Main technology date :

Main technology date :