Product Specifications

| Prod Model: |

QT6-15 |

| Main Material: |

Sand, Flyash, Cement, Crushed Stone |

| Condition: |

New |

| Name: |

Concrete Brick Making Machine |

| PCS / Mould: |

8 PCS / Mould |

| PCS / Shift: |

11500-15000PCS (390*190*190) |

| Type: |

Hydraulic Pressure and Vibrate |

Product Description

Automatic Concrete Block Machine (QT6-15)

Features:1) Uses Germany Siemens PLC control system and Siemens Touch Screen.

A. Visualization screen with easy operation;

B. Is able to set up, update and amend the production perimeters, to maximize the production output;

C. Dynamic display of the systems status, automatic trouble shooting and warning notice;

D. Has automatic-locking function, avoiding mechanical accidents caused by operational mistakes;

E. Is able to troubleshoot the machinery via teleservice...

2) Uses high-dynamic proportional and directional valves, which automatically adjust the oil flow and pressure as per specific working requirements, to buffer the hydraulic cylinder when working; Uses integrated high-pressure and soft oil pipes, with easy installation;

3) Uses multi-shaft rotating and compulsory feeding, which greatly improves the density and intensity of the blocks, and reduces the feeding time as well;

4) Integrated structure of vibrating and moulding platforms, which reduces the weight of the machine, and improves the vibrating efficiency;

5) Uses double-line aero vibration-proof system, which reduces the vibrating force on the mechanical parts, improves the using lifetime of the machine, and reduces the noise;

6) High-precision guide bearings are used to assure the precise movement between the tamper head and the mould;

7) Heavy-duty machine frame, which uses high-intensity steel and advanced heat treatment, is wear resistant.Raw Material:sand, gravel, stone, cement, can add a lot of fly ash, slag, steel slag in coal gangue, ceramic, perlite, construction waste, domestic waste and other industrial waste,etc.Technical Specifications| Model | QT6-15 |

| Cycle Time | 12-18s |

| Vibration Force | 60kN |

| Pallet Size | 850 x 680 x (8-35)mm |

| Installed Power | 31KW |

| Motor Frequency | 50HZ |

| Total Wright | 7.5T |

| Machine Size | 5210 x 3530 x 2480mm |

| | |

| Block Model | Block Size(L*W*H) | Pcs / Mould | Pcs / Hour | Pcs / Shift |

| Block | 390*190*190mm | 6 | 1440 | 11520 |

| Standard Brick | 240*115*53mm | 36 | 10800 | 69120 |

| Perforated Brick | 240*115*90mm | 18 | 8640 | 34560 |

| Floor Brick | 200*100*(60-80)mm | 21 | 4320 | 30240 |

Cement Concrete Block Machine main advantages

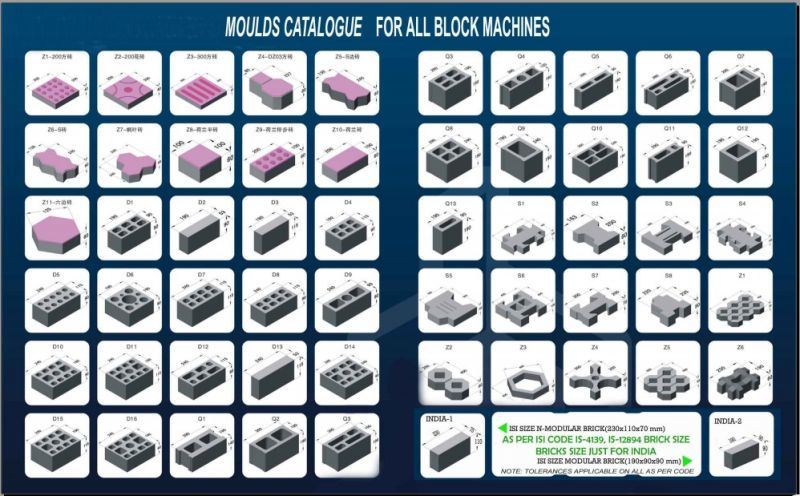

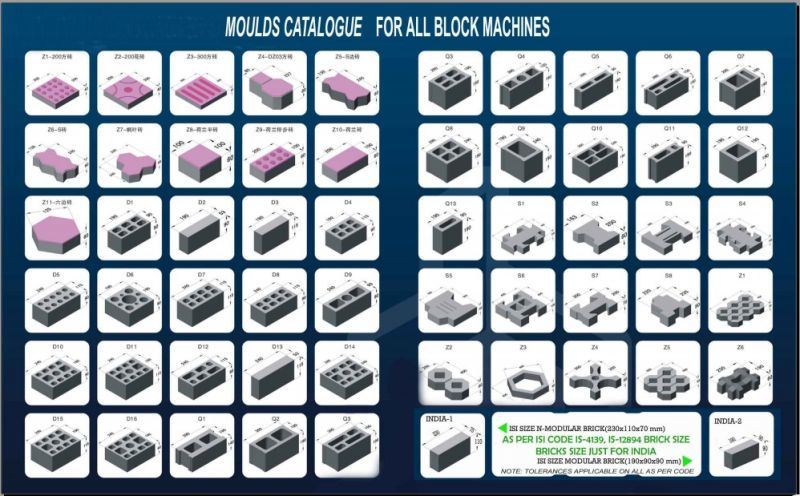

(1) Full automatic and hydraulic automatic block making machine , can produce all kinds of bricks,

and just change the moulds, such as the solid bricks, hollow blocks, paver blocks and so on.

(2) German Siemens motors

(3) Japan Mitsubishi PLC

(4) Omron travel switch

(5) The moulds: We adopt the heat treatment technique to increase the lifespan of the moulds

(6) Certificates: SGS/CE/ISO9001 2008

(7) Mould heat treatment & carburization technology

(8) Strong High-Strength Steel Structure

Cement Concrete Block Machine each part details

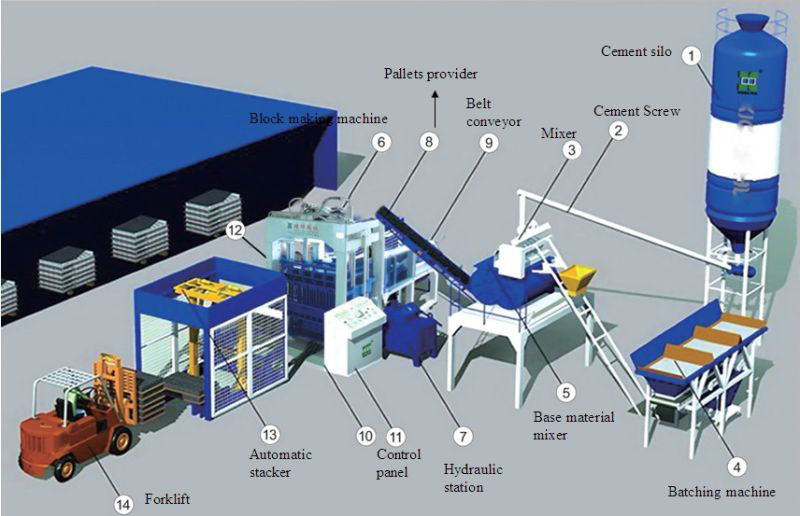

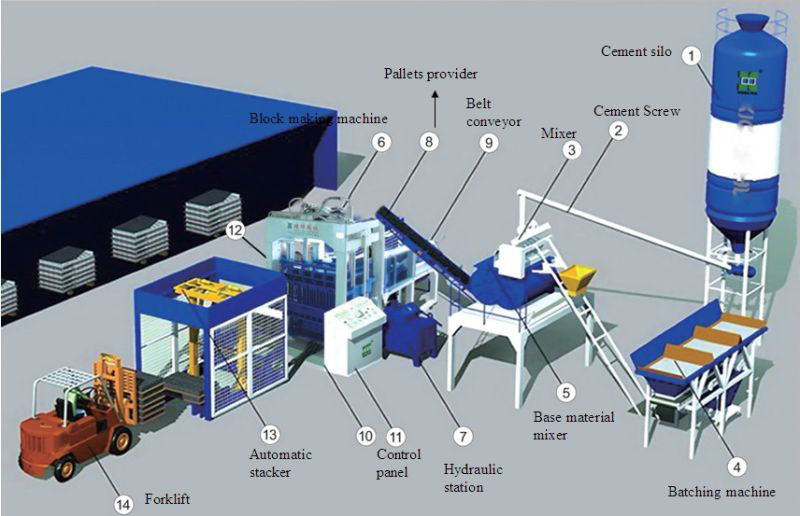

1) batching plant

function: This is the starting point of the Production process. It consists of one loading bins and one weighing bin. It also contains belt conveyers to convey materials from loading bins to weighing bin. Batching and weighing is done by PLC control. We can load different types of material into the loading bin.

2) JS750 MIXER

Function: All the ingredients are mixed in this mixture machine. The mixing time and speed is controlled by PLC. The inbuilt water pump adds water to the mix automatically, as per requirement.

3) Germen Siemens motor and Janpnese Mitsubish PLC

4) Stacker

Simple Production Line

More Details

More Details

Samples

FAQ

1.Q: Can this machine make my block?

A: We will design suitable molds according to customers' drawing/picture of blocks.

2.Q: What is your payment term?

A: T/T,L/C, Escrow or others.

3.Q: what is your delivery time?

A: Normally with delivery time within 15 days after deposit.

4.Q: What is your minimum order quantity?

A: one set.

5.Q: How about your packing and shipping?

A: Suitable for shipping, usually 20/40 feet container.

We are professional clay brick logo brick machine, concrete block machine and block pallet manufacturer, if you are interested, please come here.

Jiangsu ATOP Machinery Co., Ltd. is a company with 10 years brick machine experience, which is located in Zhangjiagang City. It is about one and a half hour's drive from shnghai international airport to our factory.

We are specialized in manufacturing all kinds of Burn-free block making machines and AAC(Autoclaved Aerated Concrete) block production line, concrete mixing machine. We exported our products to Indonesia, Malaysia, Myanmar, Vietnam and Africa. We can cooperate with you with our best service and quality.

With many technical patents and professional technical level, Our factory is well ahead of the domestic counterparts. Never slack quality, Quality is our culture. We also gained series of quality certifications such as CE, BV etc, And good market feedback. Never delay service, We are always supply customized scheme and offer the site planning and technical training for free. Enjoy lifetime maintenance.

ATOP Machinery Co. Ltd, has always been adhering to the management idea of"Integrity, Innovation, Harmony, Security, Altruism", strive to produce highest quality products, built and completed management and quality control system. With broad domestic and international sales network and excellent after-sales service team, we gain the initiative in the fierce market competition, "ATOP" brand reputation is famous in domestic and international market.

Quality is the core of our company. Advanced inspection equipment and stringent quality control tests make us through ISO9001 certification, and also we have passed the tests of National Building Materials and Mechanical Products Testing Center. Service is the guarantee of company life. Providing the customers with first-class service is our long-term and unchangeable ideas.

It is our unceasing pursuit to commit ourselves to research and develop high-quality, environmental protection and new type building materials

1. Our product has passed CE, ISO9001, BV, SGS, CTC certification.

2. We have after-sales departent in Asia, America, South America, Africa.

3. Engineers will come to you to install the machine and train workers for you.

Company name in English: ZhangJiaGang ATOP Machinery Co., Ltd

Address: Leyu Economic Development Zone, Zhangjiagang, Jiangsu, China

More Details

More Details