Bus Flooring Plywood, Truck Flooring Boards, Container Wood Floor

| Price: |

US $ 14/Piece |

| Min Order: |

1/Piece |

| Pay Type: |

L/C,T/T,D/P,Western Union,Paypal |

Product Specifications

| Formaldehyde E: |

E1 |

| Glue: |

Melamine or WBP |

| Main Material: |

Poplar |

| Thickness: |

2.5mm-30mm |

| Moisture: |

8-14% |

| Material: |

Plywood |

| Color: |

as Request |

Product Description

Linsen One-Time hot press decorative plywood is made by Russian Birch, German Beech, Okoume, Bintangor, Poplar or other equivalent top quality wood material. Veneers are bonded by modified Melamine Glue (MUF).

Face & Back veneer thickness is above 0.6mm, different grades are available according to customers' requirement. Longitudinal veneers are full rotary-cut veneers and Horizontal veneers are made by automatic CNC veneer builder.

Compared with UF Glue, this modified MUF is far more better in formaldehyde emission grade and water-resistant performance.

Characteristics:

Beautiful surface veneers, Low Formaldehyde Emission Grade, Water Proof, Strong Nail-holding power, fewest gaps and overlaps, No veneer peeling and delamination.

Application:

Internal decoration for yacht, boat, and ship.

Decorative materials for container house, camping house, and recreational vehicles.

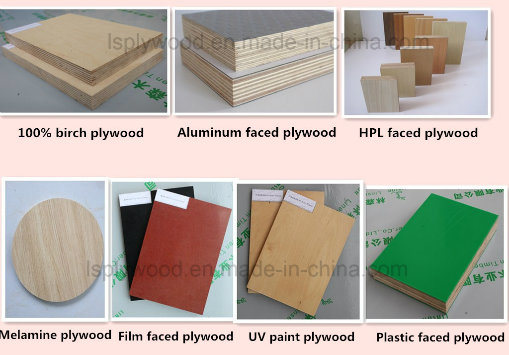

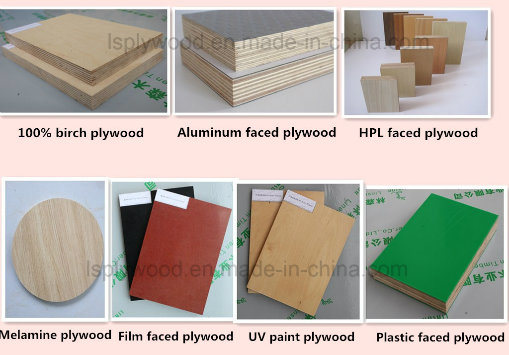

High end plywood furniture & other wooden architecture, luxury plywood packing box.≡ Kinds of our plywood sample:

| Item | Birch plywood(poplar core) | Sound insulation plywood |

| Structure | 18mm plywood | 9mm plywood+0.2mm mesh+9mm plywood |

| Material | Birch face, poplar core | 100% birch veneer |

| Glue | Phenolic resin |

| Category | Class I plywood, water boiled proof |

Formaldehyde

Emission | E1 grade |

| Face Veneer Thickness | ≥0.8mm |

| Thickness Tolerance | 18±0.5mm |

Length/Width

Tolerance | ±1mm |

| Density | About 550kg/m³ | About 680kg/m³ |

| Moisture Content | 5-14% |

| Glue Strength | ≥0.8Mpa | ≥1.0Mpa |

Flexural strength

Flexural modulus | ≥30Mpa;≥5000Mpa; | ≥50Mpa;≥6000Mpa; |

| Fire Resistant | No fire resistant processing,

if need and pls request for special. |

≡ Our products widely use for :

≡ Our advantage:

≡ Our advantage:

1) High-top quality

2) We can make the biggest size for: biggest length 10' and biggest width 6' equal 1830*3050mm

3) The material for 100% birch, 100% basswood, 100% beech or other 100% wood.

4) Curve wood

6) We can process the drawing as your request.≡ Our 4 big workshop:  ≡ Producing :

≡ Producing :  ≡ FAQ

≡ FAQ 1. What's the main business of our company?

We are the professional manufacture of the plywood, composite board, and other processed products, like cabinets or flooring of high speed train, industrial flooring, vehicle plywood, truck flooring plywood and so on.

2. Is OEM welcome by your company?

OEM or ODM is warmly welcome by our company. Hope we both parties will benefit a lot through the cooperation.

3. What is your MOQ?

Normal MOQ is 1X20'FCL, but also welcome LCL.

4. Could we get free samples?

Yes. Samples is freely prepared, but pls make freight collected by your side.

And This charge'll be deducted from total value once you order from us.

5. How can you promise the quality?

To supply the high quality board to every customer. Wanyun workers are serious in every process, every details, from sourcing the timber/veneer to check panels piece by piece. Just to satisfy every customer, and make long term cooperation.

If you are interested in our products or if you have special requirements,

Welcome to Contact Us With Any Enquiries!

LINSEN WOOD INDUSTRY Co., Ltd located in the shenzhou city, hebei province, establish in 1997 and concentrate on the plywood produce, all kinds of interior of the vehicle as well as the composite plywood. At present, with area for more than 800, 000 square meters and more than 100 workers.

In the fields of trains, buses, vans, ships, containers, industrial equipment, construction and furniture, Linsen is offering a complete range of products ranging from standard panels to modular components.

Our products mainly including three section:

1, plywood

Our plywood are all use the full veneer unitization craft to produce, stable and reliable qulaity.

2, composite plywood

By combining our plywood with other different materials (such as HPL, rubber damping layer, honeycomb core, PVC, aluminum, etc. ) to produce a composite sheet with different properties of flame retardant, noise insulation, abrasion resistance and slip resistance.

3, plywood processing and assembly

We have electronic cutting saws, CNC machining centers, automatic edge banding machines and other precision machining equipment, according to the drawings to processing by the plates. Supplemented by reliable parts, assembled into finished products.

Our company has a strict quality management system, has obtained ISO9001: 2008 quality management system certification. From the procurement of raw materials to product production, testing and packaging, strict quality control covers every aspect.

Our long-term partners include ZhongKe, Yutong Bus, FAW-Volkswagen, GuJia Household as well as well-known enterprises at domestic and overseas such as EISENMANN, DURR.

In 2016, we newly established LINSEN RAIL BUS EQUIPMENT Co., Ltd, focusing on the development of rail passenger car interior products business. When you need high-quality composite panels or vehicle interior products, Linsen is your best choice!