Product Specifications

| Prod Model: |

Custom Air Conditioner Foam Part |

Product Description

Custom Lightweight Anti-impact Insulating EPP/EPS Foam Suction Plate for Air Conditioner

| Service | OEM/ODM Factory |

| Customized Logo | Accept |

| Material | High Durable EPP/EPS Foam |

| Size | Per Customer's Drawing |

| Color | Pink/Black/White(custom) |

| Feature 1 | Lightweight |

| Feature 2 | Shock-proof |

| Feature 3 | Non-toxic & Total Eco-friendly |

| Feature 4 | Insulating |

| Function | Air Conditioner Foam Parts |

| Additional Service | Mold Manufacturing & Rapid Prototyping |

| Certificates | SGS |

| Packing | In Polybags or Cartons |

| Delivery | 15~30 Days after Order Confirmed |

| Payment | T/T, L/C(other method can be accepted if possible) |

EPP details(EPS is similar to EPP)

EPP is a plastic material with a wide range of applications and high engineering performances. Thanks to its specific properties, it can be used in various areas to improve technical performances and the absolute value of the end product.

Resistant and non-deformable

EPP has a very high strength-to-weight ratio, with exceptional load bearing quality, reducing weight and volumes. Its high energy absorbing property makes it the ideal material to build, for instance, protection components in the automotive and logistic industry.

Lightness

EPP is an ultra light material. It allows a significant weight reduction of the end product, with a substantial increase of resistance and efficiency.

Acoustic insulation

Porous EPP guarantees acoustic insulation, with excellent performances in the automotive industry.

Thermal insulation

When temperature resistance is required, EPP provides thermal insulation: food, medical supplies and temperature sensitive products. EPP thermal insulation makes it the ideal material to be used in thermohydraulics.

Recyclable

EPP is 100% recyclable.

EPP Solution

EPP has been used as a material of choice in automotive applications for several years, from passive safety products such as side impact energy absorbers in door panels, head restraints and seat cores, seating and knee protection, to stowage applications.Here, the exceptional strength to weight ratio enables storage of tool kits, boot liners, load floors and console components.

EPP manages impact energy by absorbing it, then returning to shape. It is ideal for multiple impact protection such as vehicle crash applications, and is widely used in automotive interiors to improve passenger safety for side impact protection, Knee protection, A, B, C pillars, Instrument panel components, and Head restraints.

Expert design and unique material properties enables EPP bumper systems to deliver crash performance and pedestrian safety to Euro NCAP standards set- against increasing space-restriction and styling demands.

An important safety benefit of EPP is its ability to withstand repeated impact without significant deformation and to return to their original shape following dynamic stress. In addition to vehicle components, this multiple impact protection, lightweight and design flexibility makes EPP ideal for personal protective equipment also.

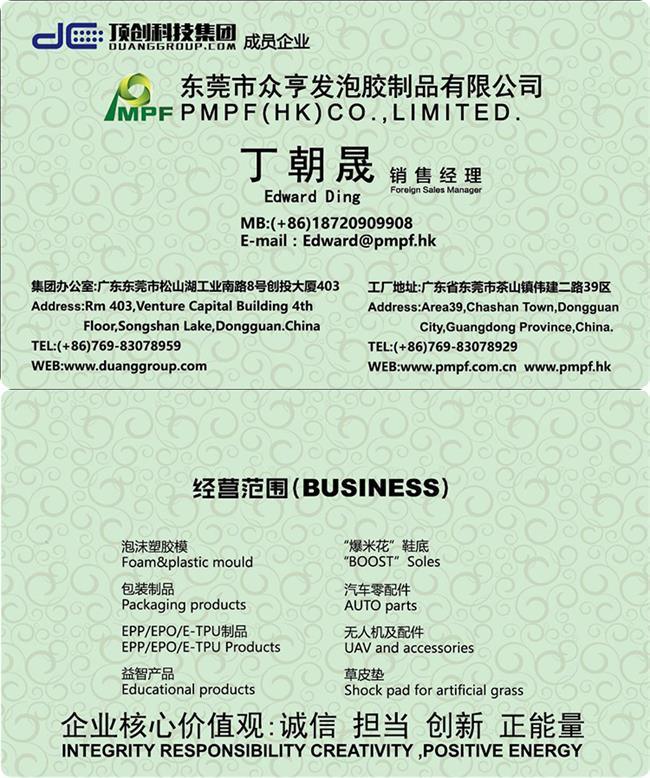

Company Info

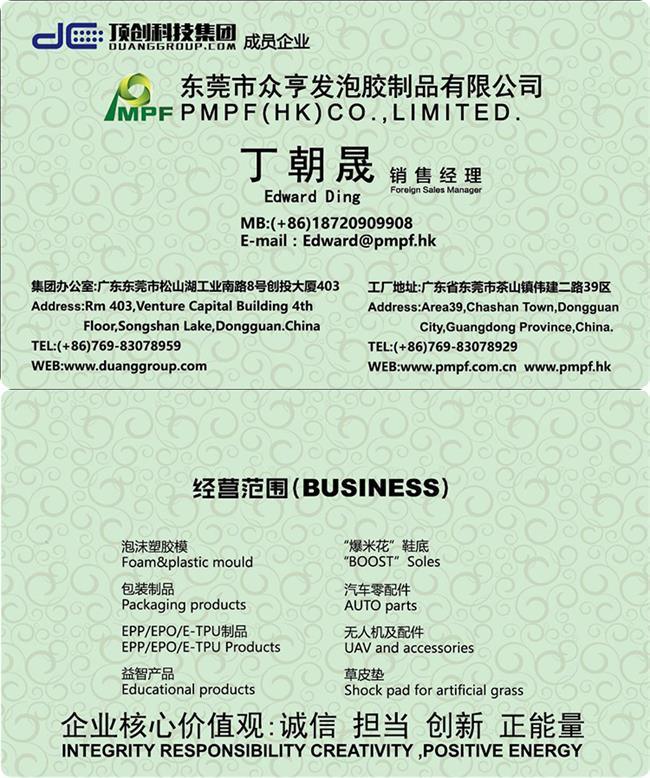

Our PMPF factory is specializing in the molded EPP (Expanded Polypropylene), EPS (Expanded Polystyrene), EPO (Expanded Polyolefin) and ETPU (Expanded Thermoplastic Polyurethane) foam products. We have good advantage in rapid prototyping made by CNC machine from EPP foam block, EPS foam block or EPO foam block, and also plastic injection moulds are available for you.

We have our own EPP/EPS/EPO/E-TPU foam moulding machines in our plants and we also assorted with CNC workshops equiped with Milling machine, EDM machines that make high quality aluminum mold toolings and plastic injection molds for us.

Our Production Line:

EPP Foam Products:

- Packaging Boxes (Take-out delivery boxes, cooler boxes, electronics or electric appliance packaging, medical packaging and any other item packing)

- Structural components (Air-condition foam parts or any other parts)

- Protective material or cushions (Baby carrier liner or any other lightweight but durable liner)

- Hand throwing plane or rc model plane

- Artificial grass/shock pad

- Toy blocks

- Foam Trays

- Foam yoga roller

- Helmet (Bicycle helmet, motorcycle helmet, safety helmet and etc)

- Foam sheets (Products underlay or any other usage)

- Interlocking Shock pad (For indoor decoration, underlay for garden or artificial grass)

- Auto foam parts (Bumper core, sunshade, seat liner, tool box and any other foam parts)

Or any other foam products per customer's drawing. EPS Foam Products:- Packaging Boxes (Take-out delivery boxes, cooler boxes, electronics or electric appliance packaging, medical packaging and any other item packing)

- Structural components (Fireplace Foam vent parts or any other parts)

- Protective material or cushions

- Foam Trays

- Helmet (Bicycle helmet, motorcycle helmet, safety helmet and etc)

- Foam sheets (Construction material like sandwich panel or any other usage)

Or any other foam products per customer's drawing. EPO Foam Products:- RC model plane

- Flying wings

- Helicopter or quadcopter

- UAV or FPV

- Foam sheets

Or any other foam products per customer's drawing. ETPU Foam Products:- Ultra boost foam insoles

- Ultra boost foam midsoles

- Boost foam sheets

Or any other foam products per customer's drawing.

Certificates

Δ TS 16949:2009 & ISO 14001:2015

Δ SGS

Packaging & Delivery

Packaging: in polybags or cartons (customized)

Delivery: 15~30 days after order confirmed

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample available.

* View our Factory.

After-Sales Service

* Inferior-quality product will be recalled.

* Any probelm will be sovled ASAP.

Name Card

FAQ

1. What's your typical procedures of OEM production business?

--Customer send us RFQ, material requirement, foam density, color, quantity, etc;

--Customer send the required part's 3D model, design drawing file, or sample;

--PMPF sales and engineers checking customers' drawing file/samples, offer feedback on design and suggestion, provide quotation for mold tooling and parts;

--Customer confirm the prices and agree to start mold tooling process;

--PMPF starts mold tooling and prepare raw material for first sample part run;

--Mold tooling completed, first sample run started and send samples to customer for approval;

--Customer's approval of samples and arrange mass production;

--PMPF starts mass production;

--Customer pay off all related cost

--Arrange shipping and delivery.

2. What are the available EPP/EPS foam densities and colors?

--Denstiy available now: 20g/L(1.25pcf)-180g/L(11.25pcf);

--Colors available now: White, Black, Pink, Grey, Orange, Blue, Yellow, Rose Red.

3. What's the normal lead time of material purchasing, mold tooling and first samples?

--Material purchasing: 5-7days;

--Mold tooling: 20-25days;

--First samples: 3-5days.

3. What's the software PMPF engineering used and the accepted part drawing file format?

--Software: UG NX10.0, ProE 5.0, Creo 3.0, Solidworks, AutoCad;

--File format: IGS, STEP, SLDPRT, X_T, CATPart.

4. What's the min form wall thickness can be achieved?

--Thickness: 3mm-4mm

5. Whether PMPF can design based on customer's idea and samples?

--Yes

6. Whether hand made prototypes available?

--Yes, PMPF can make prototypes by CNC machining from EPP/EPS/EPO/ETPU foam blocks

7. What's the accepted shipping terms?

--Shipping terms available: EXW, FOB Shenzhen, CFR, CIF, DDU

PMPF (Dongguan City Prosperous Mass Polyfoam Co., Ltd) was established in the year 2011, the company is a morden technology driven company with a collection of expertise in the entire industry and specialized in mould design, product development, new material development and application. PMPF factory is situated in Chashan Town of Dongguan City with a 15000 square meters floor coverage and over 100 employees including management, know-how, quality and workshop workers.

The PMPF factory equiped with 17sets foam moulding machine, including 2sets K1216 type machine, 7sets K1214 type machine and 9sets K813 type machine. All the machines are available for producing EPP, EPS, EPO, E-TPU foam products. Our factory also has the capablity to expand EPS/EPO foam raw material to different density beads with expansion machine by our ownself. To ensure the quality can meet our customers' demands and aimed to be the leader in the industry, the products are controled and random checked from the start of moulding production line to the final packaging and transporting process through our QC staff at any time.

PMPF take the leader of market trends, keep innovation and development, actively dedicated to develop newly eco-friendly packaging materials including high end EPP, EPO and also EPS foam products. The PMPF manufacturing and selling polyfoam products business scope is very wide, such as foam products, LCD packaging products, plastic products, general packaging products, sports protection products, mould, foam toys, automotive cushion padding products, car sun visors, helmet liners, model planes, etc.

To meet the market requirement and produce worthy products for human beings, PMPF based on continously innovation and development, estiblished its brand by technology as our duty, driven by the current market demands. Now PMPF has become an approved supplier to many well-known telecom brands and automotive brands such as: Huawei, ZTE, LG, TCL, Parrot GAC, TESLA, FUTURIS, etc. And we also have become material supplier and parts manufacturer for many famous consumer electronics companies such as Parrot, Jabil and Flextronics. PMPF also has built all-round business cooperative partnership with many other famous UAV and FPV drone aerial photography companies around the world. PMPF company takes "Liability, Responsibility, Positve Energy" as our root personnel policy. On that basis, PMPF has gathered a lot of multi-industry expertise and talents to provide the best service and products to the customers and consumers. We believe in that our centralized talents with the advanced know-how will contribute to the customers' product and service in occupying their markets.

Under the PMPF's "Quality First" tenet, the high quality products and services provided by PMPF will undoubtedly help our customers to broad their development space in a big level.

PMPF will always keep the environmental protection in mind, following the path of high end EPP/EPO foam products application market, carrying forward with the eco-friendly and innovation packaging concept, to set up a thanksgiving and rewarding coporate culture, serve our loyalty customers through wholeheartedly attitude and best technology, build a better future together.