Product Specifications

| Prod Model: |

N/M |

| Color: |

White, Black, Yellow, Gray |

| Materials: |

High Technical Ceramic |

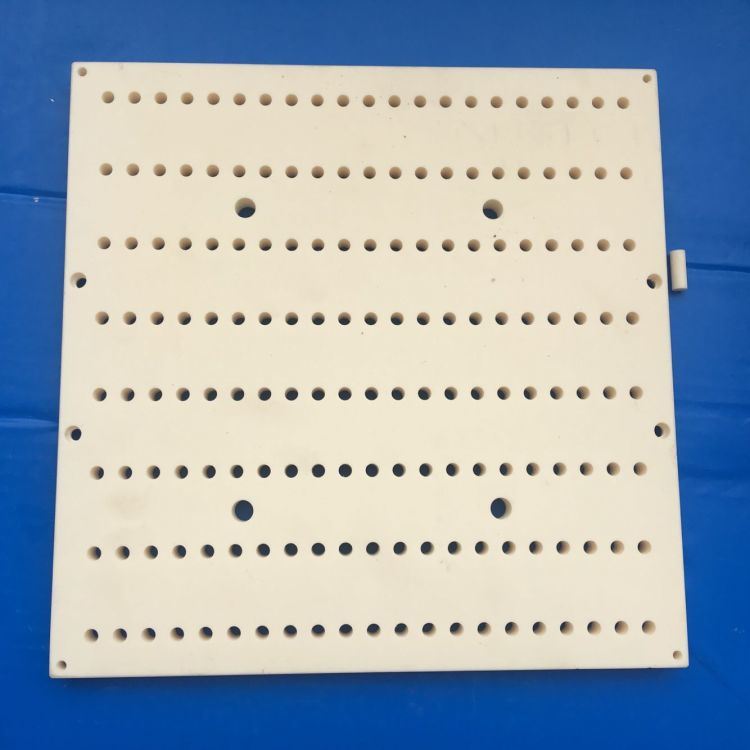

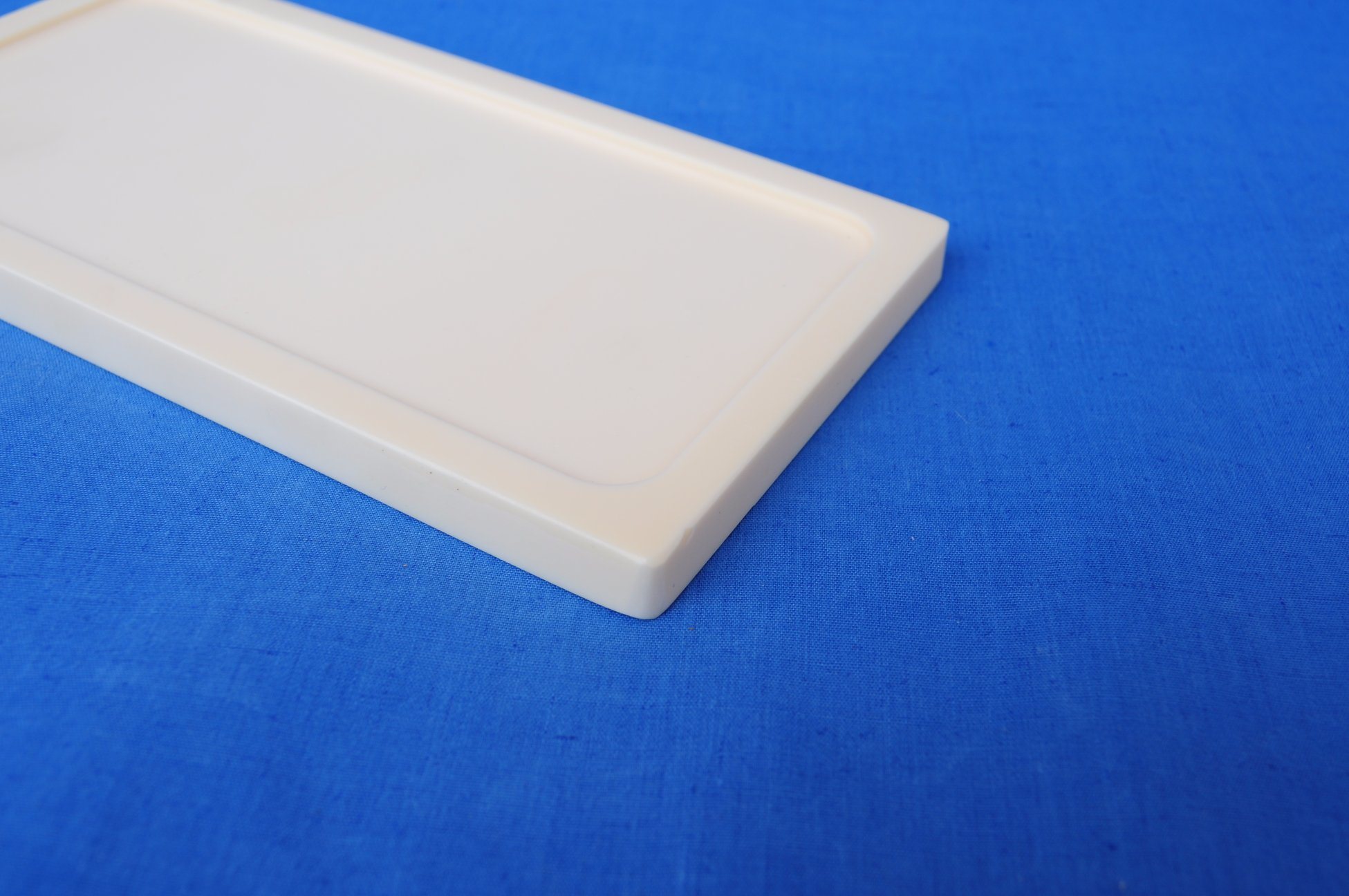

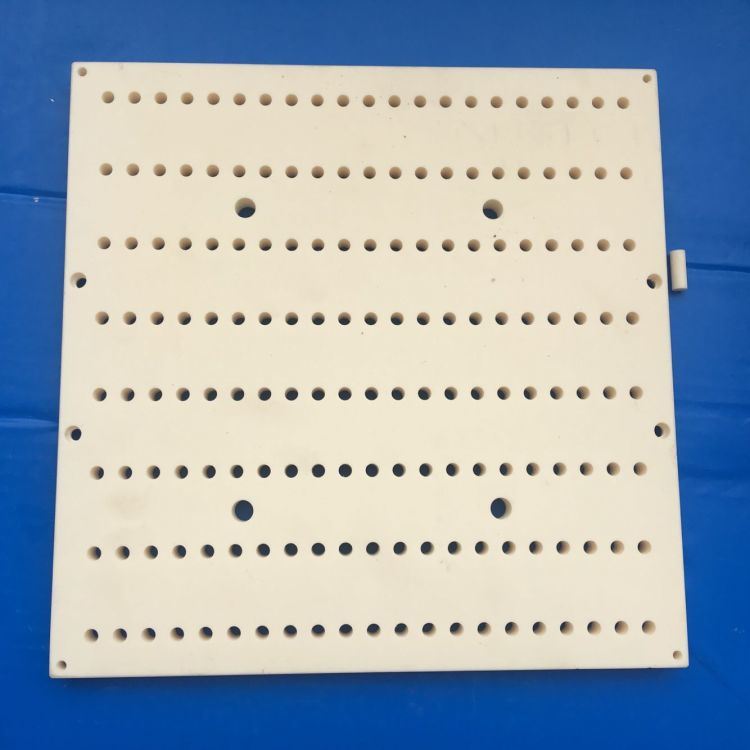

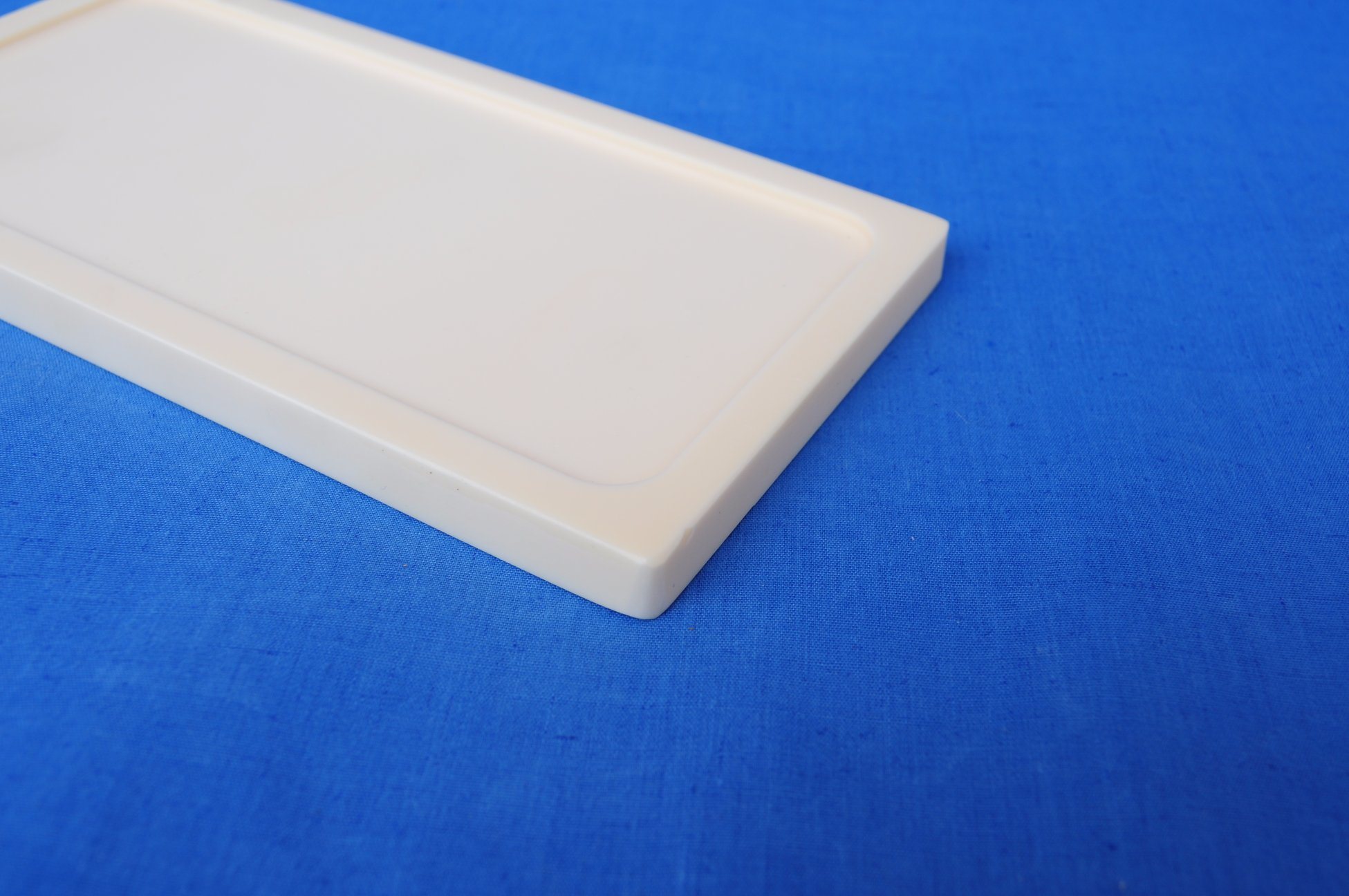

| Product Name: |

Alumina Ceramic Plates |

| Features: |

Good Flatness and No Sharp Angles |

| Advantages: |

High Temperature Resistance and No Deformation |

Product Description

Industrial Ceramic TilesSpecifications1.Material:Alumina, zirconia, silicon nitride

2.Method of moulding:dry pressing

3.Corrosion resistance

4.Custom design

5.Eco-friendlyThe ceramic tiles has very good performance at high temperature sintering, good thermal impact, small thermal expansion coefficients and very good creep resistance, so, it can be used in high-temperature kilns and can working under 1700 ºC high temperature condition and for industry such as petroleum, mine, steelworks, electric plant.

| | Unit | 95% Al2O3 | 99% Al2O3 | ZrO2 | GP-Si3N4 |

| Color | - | white | ivory | white | gray |

| Density | g/cm³ | 3.70 | 3.90 | 6.04 | 3.31 |

| Water Absorption | % | 0 | 0 | 0 | 0 |

| Young's Modulus | Gpa | 280 | 350 | 205 | 295 |

| Vickers Hardness | Gpa | 14 | 20 | 12 | 18-20 |

| Flexural Strength ( at R.T. ) | Mpa | 280 | 300 | 900 | 650 |

| Compressive Strength ( at R.T. ) | Mpa | 2000 | 2500 | 2200 | 2200 |

| Thermal Conductivity ( at R.T. ) | W/(m.K) | 18-25 | 30 | 2.2 | 25 |

| Thermal Shock Resistance | ΔT(°C) | 220 | 180-200 | 280-350 | 450-650 |

| Max. Working Temperature ( at R.T. ) | °C | 1500 | 1700 | 850 | 1200 |

| Volume Resistivity ( at R.T. ) | Ω.cm | >10^15 | >10^14 | >10^12 | >10^14 |

| Dielectric Constant (1 MHz at R.T. ) | - | 9.50 | 9.80 | 26 | 8.20 |

| Dielectric Strength | kV/mm | 16 | 22 | - | 16 |

Our Services

Why choose us?

We are specialized advanced technical ceramics manufacturer,who have founded 8 years.The quality and service of the products are guaranteed.

We provide customized parts according to user's requirement.We produce and process non-standard components to satisfy the customer's need.

Pre-sale service: Professional technical persons will choose suitable materials for you due to using environment about theceramic parts.

The sale of services: If you need,we can provide the sample for you to go on testing,and also provide technical help and supports for you.

After-sales service: Accept any repair of the product, help to improve technology for customer. And also provide long-term technical help and support for you!

FAQ

1. How can I get an offer?

You can send your drawing with technology requirements and inform your purchase quantity. If possible, please inform what is your part used in. We will confirm what is the most suitable material and quote our best price to you in 24 hours.

2. Can you provide the free samples?

Yes, we can provide the sample free of charge if we have the stock product the same as what customer required, but the freight is on your side.

3. Can you accept OEM & ODM?

Yes, we can produce the products according to your demand and drawing.

Jiangsu Xindelong Precision Ceramics Co., Ltd. is located in Yixing Economic Development Zone, which is famous for China all over the world, the company name of Yixing Tigar Precision Ceramic Co., Ltd is our subsidiary.

Xindelong Ceramics has dedicated in manufacturing and processing precision parts/components with a wide range of products and services covering high precision ceramics and high performance ceramics, such as machinery ceramic parts/components, textile ceramic parts, electronic ceramics parts, engineered ceramic components, pump components, valve components, flow components, wear components, corrosion resistant ceramic parts, high temperature ceramic parts, welding ceramic parts, ceramic parts for semiconductor etc. The raw materials is including alumina, zirconia, silicon carbide, silicon nitride, mullite, cordierite and steatite, PBN/ALN, BeO and graphite and so on.

Xindelong Ceramics has complete facilities, such as CNC machines, internal grinding machines, cylindrical grinding machines, centerless grinding machines, double surfacce lapping machines, vibration polishing machines, honing machines, and electron microscope, three-coordinates measuring machine, hardness tester, surface roughness instrument-to enable us to manufacture technical ceramic components to the highest specifications.

Our current customers comes from USA, Canada, Germany, England, Italy, Spain, Denmark, Mexico, Brazil, Argentina, Korea, Singapore, Thailand, Malaysia and so on.

Our company always insists on quality first, the supremacy of the purposes of the users. We'd like to cooperate sincerely with enterprises at home and abroad to create a win-win future.