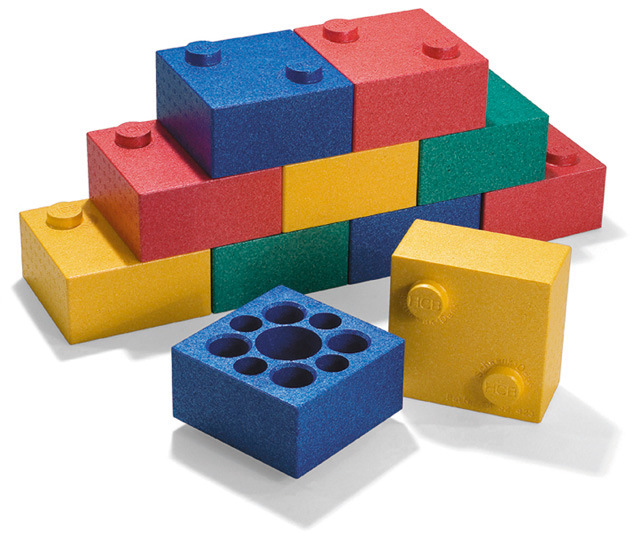

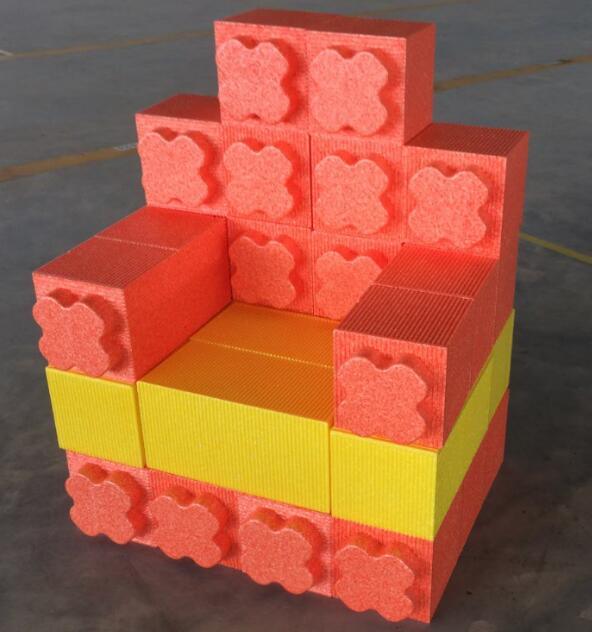

EPP Foam for Children Building Blocks Toys

| Price: |

US $ 1-2/Piece |

| Min Order: |

1000/Piece |

| Pay Type: |

T/T |

Product Specifications

| Prod Model: |

PMPF EPP block |

| Foam Material: |

Jsp EPP |

| Foam Density: |

30g/L |

| Foam Color: |

Orange,Yellow,Blue,Grey,Pink,White,Black |

| Advantage: |

Lightweight |

| Feature: |

No Harm |

| Application: |

Amusement Park |

| Type: |

Building Blocks |

| Age: |

37-96 Months |

| Material: |

EPP Foam |

| Toy Department: |

Boys and Girls |

| Plastic Type: |

EPP |

Product Description

EPP is particularly suitable for the production of toys in child-friendly forms and colors. The foam is extremely robust and durable, while at the same time it is as light as a feather. EPP is available in a variety of colors and allows an almost unlimited design flexibility. Furthermore, the foam plastic convinces by its dimensional stability and its ease of processing. EPP is water resistant and therefore suitable for outdoor applications. Moreover, also different cleaners cannot harm the material. Finally, the material does not comprise any pollutants or plasticizers such as phthalates and therefore absolutely fulfills the requirements for use in all kinds of toys.

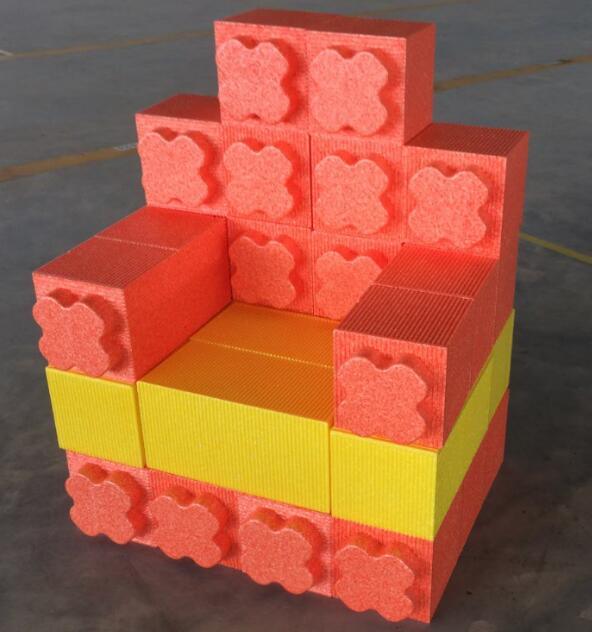

Due to its light weight and the freedom of part design EPP can be brought in the form or a frisbee or a model airplane. However, it can also be used as building blocks and high chairs of different sizes and colors, which then can be found in childrens' rooms, kindergartens or play corners.

Another game classic made out of EPP: The ball track viavario is particularly robust, yet still elastic and versatile. The low weight of the individual components of only about 50 grams makes the ball track easy to play for children of almost each age. Thanks to the dimensional accuracy of the material and therefore the building blocks, children can individually and simply assemble and disassemble their path in many different ways.

There are countless of other ideas where EPP can be used in the toy industry in the near future. Thanks to its recyclability, EPP is a future-oriented material also in this industry. It can be crushed and brought back to the product cycle as polypropylene granulate. This means that if a toy has become boring, new and exciting products can be developed from it.

If You also have ideas about light toys made out of EPP? We PMPF can help you realize your ideas to final product.

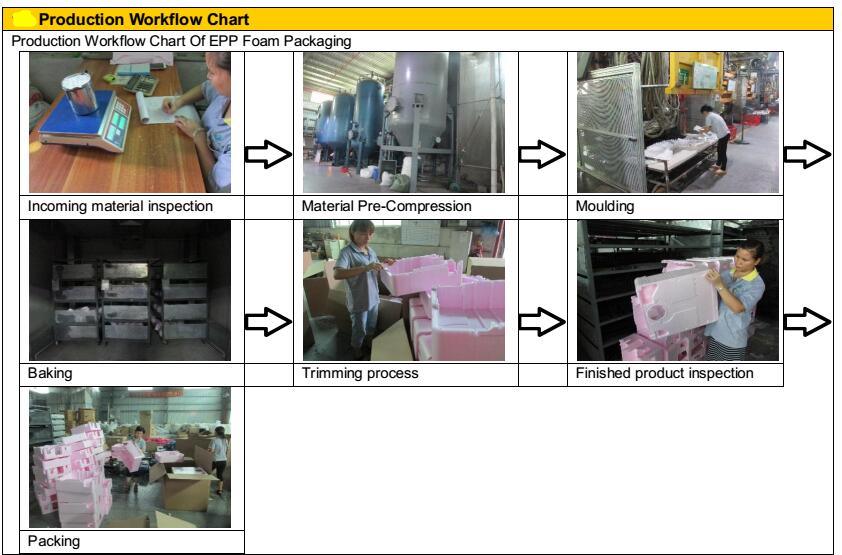

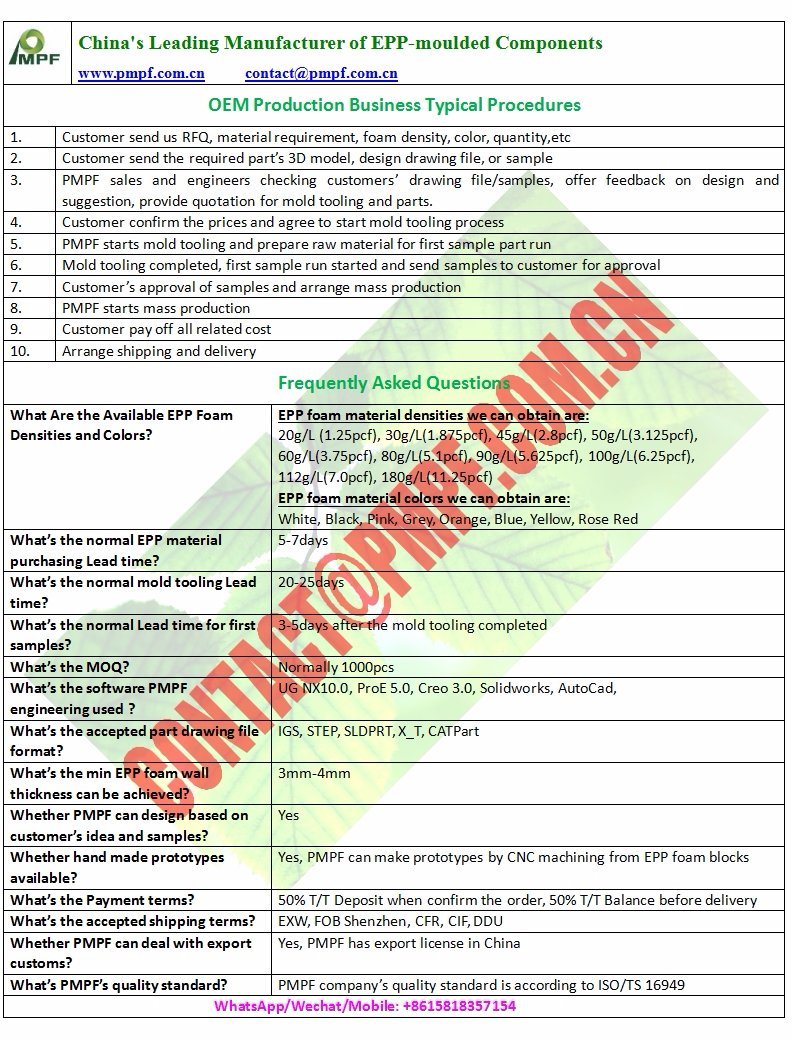

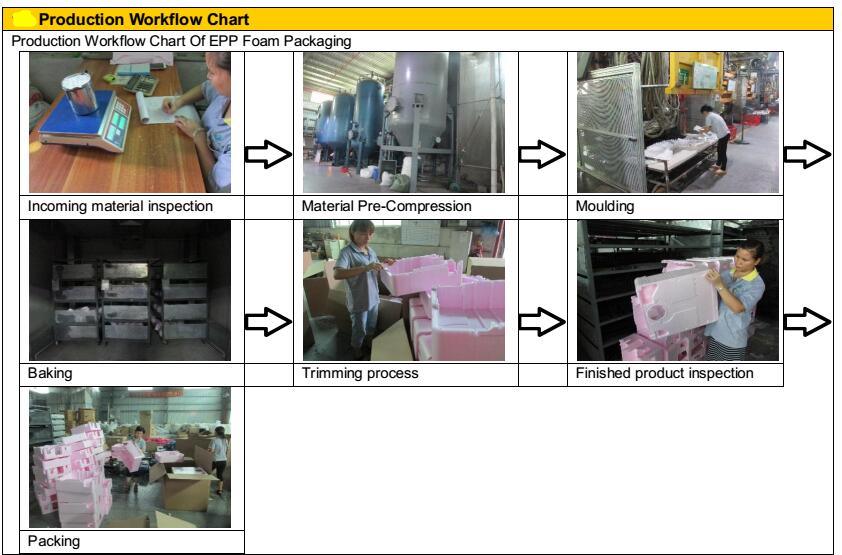

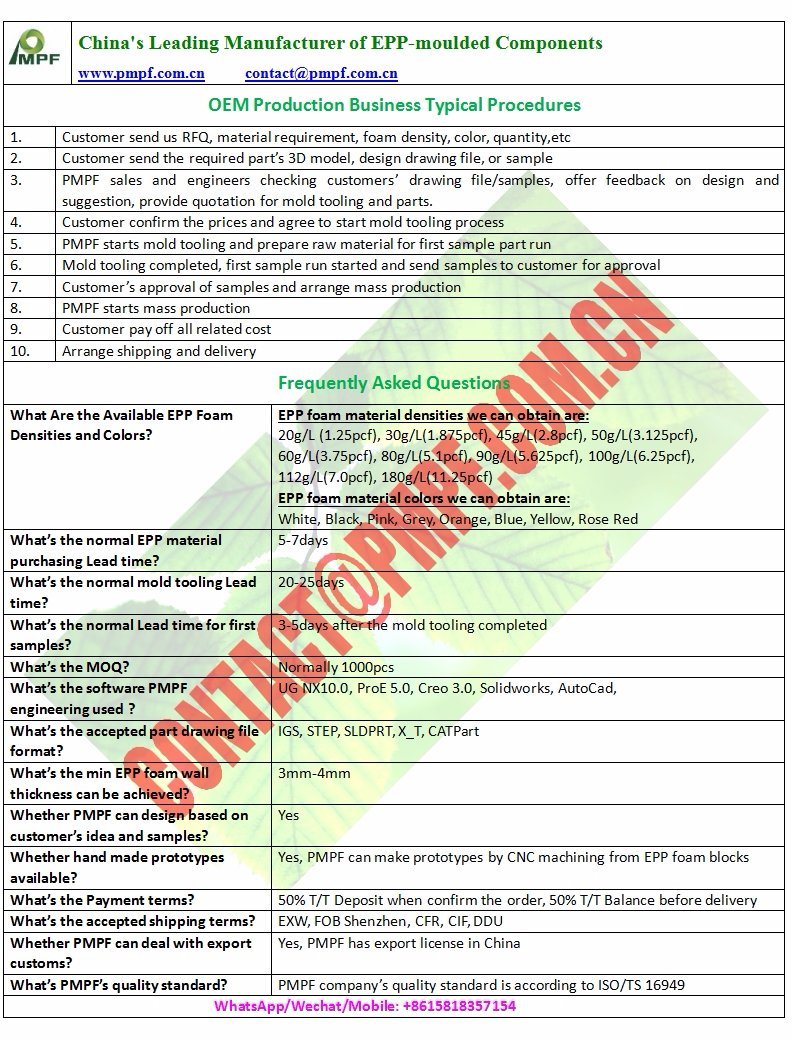

PMPF (Dongguan City Prosperous Mass Polyfoam Co., Ltd) was established in the year 2011, the company is a morden technology driven company with a collection of expertise in the entire industry and specialized in mould design, product development, new material development and application. PMPF factory is situated in Chashan Town of Dongguan City with a 15000 square meters floor coverage and over 100 employees including management, know-how, quality and workshop workers.

The PMPF factory equiped with 17sets foam moulding machine, including 2sets K1216 type machine, 7sets K1214 type machine and 9sets K813 type machine. All the machines are available for producing EPP, EPS, EPO, E-TPU foam products. Our factory also has the capablity to expand EPS/EPO foam raw material to different density beads with expansion machine by our ownself. To ensure the quality can meet our customers' demands and aimed to be the leader in the industry, the products are controled and random checked from the start of moulding production line to the final packaging and transporting process through our QC staff at any time.

PMPF take the leader of market trends, keep innovation and development, actively dedicated to develop newly eco-friendly packaging materials including high end EPP, EPO and also EPS foam products. The PMPF manufacturing and selling polyfoam products business scope is very wide, such as foam products, LCD packaging products, plastic products, general packaging products, sports protection products, mould, foam toys, automotive cushion padding products, car sun visors, helmet liners, model planes, etc.

To meet the market requirement and produce worthy products for human beings, PMPF based on continously innovation and development, estiblished its brand by technology as our duty, driven by the current market demands. Now PMPF has become an approved supplier to many well-known telecom brands and automotive brands such as: Huawei, ZTE, LG, TCL, Parrot GAC, TESLA, FUTURIS, etc. And we also have become material supplier and parts manufacturer for many famous consumer electronics companies such as Parrot, Jabil and Flextronics. PMPF also has built all-round business cooperative partnership with many other famous UAV and FPV drone aerial photography companies around the world. PMPF company takes "Liability, Responsibility, Positve Energy" as our root personnel policy. On that basis, PMPF has gathered a lot of multi-industry expertise and talents to provide the best service and products to the customers and consumers. We believe in that our centralized talents with the advanced know-how will contribute to the customers' product and service in occupying their markets.

Under the PMPF's "Quality First" tenet, the high quality products and services provided by PMPF will undoubtedly help our customers to broad their development space in a big level.

PMPF will always keep the environmental protection in mind, following the path of high end EPP/EPO foam products application market, carrying forward with the eco-friendly and innovation packaging concept, to set up a thanksgiving and rewarding coporate culture, serve our loyalty customers through wholeheartedly attitude and best technology, build a better future together.