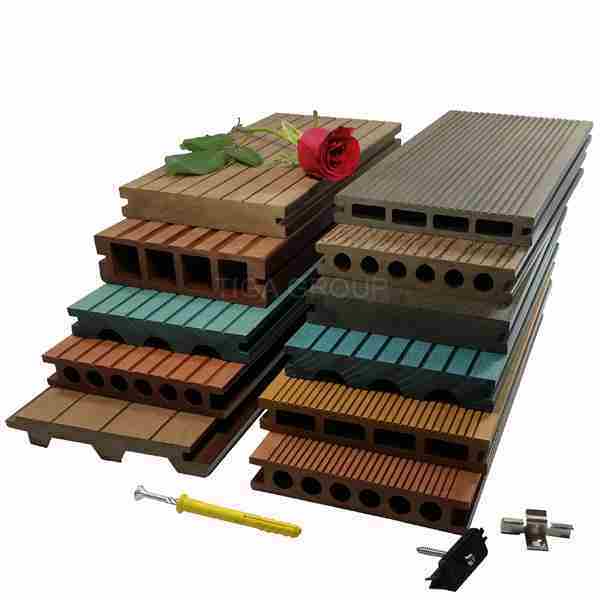

Factory Price Eco WPC Outdoor Flooring/Wood Plastic Composite Wall Cladding

| Price: |

US $ 8-12/Square Meter |

| Min Order: |

100/Square Meter |

| Pay Type: |

L/C,T/T,Western Union,Paypal,Money Gram |

Product Specifications

| Prod Model: |

TIGA-WLWPC016 |

| Thickness Range: |

8-50mm |

| Width: |

25-60mm |

| Length: |

10-11800mm |

| HS Code: |

39189090 |

| Color Type: |

as Per Request of Customers |

| Material: |

Wood + HDPE +Additives |

| Surface: |

Sanded, Brushed or Embossed |

| Warranty: |

10 Years |

| Usage Type: |

Outdoor, Swimming, Garden, Park, Yard, Balcony |

| Technique: |

Extrusion |

| Thickness: |

8-40mm |

Product Description

Outdoor WPC floor tiles is an attractive and dependable decking solution that will withstand the test of time.Each piece is knot free and consistent in size, colour and length,therefore eliminating the search for the perfect piece. It looks, smells and handleslike wood but has the durability of plastic.

The process of WPC decking floor

WPC decking board is made by special process(Extrusion) from disused plant fiber (wood/bamboo powder) and high density polyethyne(HDPE). All the product process is based on high temperature and high pressure under the supervise of our technician to make sure the good quality and natural & elegant looks of our wooden plastic composite products.

The main process is as following: Mixing, Granulation, Extrusion And then there will be embossing/sanding and cutting to complete. We can embossed natural wood texture, and cut them into different length.

Advantage& Feature:

1.Looks and feels like nature wood ;

2.100% recycle, Can be decomposed,saving forest resources;

3.Easy to install and clean, low labor cost and labor cost;

4.Waterproof,mildew resistant,Moisture resistant, no rotting, low flame spread;

5.Unaffected by termites and other insects;

6.Stable over a wide temperature range, suitable from -40'C to 60'C ;

7.Barefoot friendly,anti-slip, resistant to cracking and splitting ;

8.High capacity of UV-resistance, Fade resistant Durable ;

9.Available in different colors and wood grain design ;

10.Green ecological, Innovative technology, Lifestyle

Packaging & Shipping

1. WPC Boards will be wrapped by shrink foil for protection.

2. Accessories like screws, clips and end-caps are packed in carton boxes.

3. WPC decking boards are covered by nylon fabric for extra protection and strapped by PE belts for stability.

4. Pallets are loaded into containers within TIGA's factory by professional forklift drivers.

The details of High Quality Outdoor Composite WPC Decking Flooring

| Material | 35% environmental plastic materials(Grade A Recycled HDPE ) 55% natural wood fiber 10% chemical additives. (Anti-UV agent, Anti-oxidation agent, stabilizers, colorants, anti fungus agent, coupling agent, reinforcing agent, lubricants.) |

| Surface Treatment | Big Groove, Small Groove

Wood Grained

Sanded |

| Weight permeter | 2.4 kg/m ,2.5 kg/m ,2.58 kg/m ,2.8 kg/m ,3.4 kg/m ,2.54 kg/m ,4.5 kg/m ,

3.7 kg/m ,6.2 kg/m ,7.7 kg/m ,1.15kg/m,0.9kg/m,etc.

Custom made |

| Size | 140x25mm(Hot),140x30mm,140x35mm,146x22mm,150x25mm

135x25mm,144x12mm,200x18mm,160x80mm

136x25mm,70x10mm(Hot),150x23mm,85x13mm(Hot),200x50mm,etc.

Custom made,For more size,please send an inquiry to us. |

| Application | Garden, Lawn, Balcony, Corridor, Garage, veranda |

| Installment | Step 1:Put the keel in the bottom with the recommended 30-40cm distance

Step 2:Dig a 1.5cm-deep hole and put the nail in.

Step 3:Combine the two boards and tighten the screw. |

Quality Control

Quality is our top priority. We know that WPC products are usually used in large-scale projects so any quality issue can have devastating effect on our clients' finance and reputation. TIGA will not allow this to happen. From controlling wood powder particle size; analysing plastic liquidity to compression tests. We are doing everything we can to ensure our products are of top quality.

Coordinated Teams

TIGA is not just a factory. We have a professional R&D team and an experience trading team. They alway work together to provide the best solution for our clients. Our trading team is constantly bringing back feedbacks from our customers to help our R&D team further improve our existing products whilst our R&D team experiments on a daily basis to create new features for WPC.

Tiga Group, as a member of the House Structure Association, branch of China Steel Structure Association and other associations, is one of the most powerful enterprises of steel structure and temporary building projects in Henan Province and in China. Tiga Group is an ISO 9001: 2000 registered enterprises and is appraised as AAA grade credit enterprise by Construction Bank of China, Qingdao Branch. Tiga Group has passed the approval of CE and SGS

Tiga Group is a high tech enterprise and is headquartered in Zhengzhou High Tech Development Zone. Tiga Group is a comprehensive enterprise of design, producing and installation. Now the group has three branches: Tiga Building Facility Company Limited, Tiga Steel Structure Company Limited, and Tiga Modular House Factory.

Tiga Group has leading R & D capabilities and technology advantages, and its products such as steel structure series, modular house series, and light steel sandwich panels series and roofing sheeting series are widely used in industry, traffic, city construction, commercial and other temporary accommodation. With the advanced technology, full products range, excellent sales and service teams, Tiga's products are sold throughout the home and abroad markets. Tiga Group is a supplier of the series products for the country's key projects, such as the Olympic Sailing Center, bay bridge of Jiaozhou Gulf, Qingdao cross sea tunnel, etc. Tiga Group has the right of import and export, and its products have been exported to over 110 countires, such as, the UAE, Saudi Arabia, Oman, Angola, Equatorial Guinea, Libya, France, Poland, Romania, Russia, Australia, the Philippines, Indonesia...etc.

Tiga Group is dedicated to the developing the resource saving, environment protection products to enhance urban civilization and improve the living conditions. Through the incessant revolution in construction field, the new steel structure industry may achieve product standardization, modularization, universalization. Insisting on the maximization of customers' interest, Tiga Group's objective is to be the leader in the steel structure and temporary building field with the high quality products, and professional, efficient service.