Product Specifications

| Prod Model: |

QT10-15 |

| Molding Area: |

1025*810mm |

| Molding Period: |

15-25s |

| Weight Of The Host Machine: |

14t |

| Host Machine Power: |

45.38kw |

| Vibration Force: |

100kn |

| Mixer Model: |

Js750 |

| General Water Consumption: |

12t/Day |

| Factory Area: |

300m2 |

| Motor Brand: |

ABB or Siemens |

| PLC Control System: |

Mitsubishi |

| Certification: |

BV Soncap Coc |

Product Description

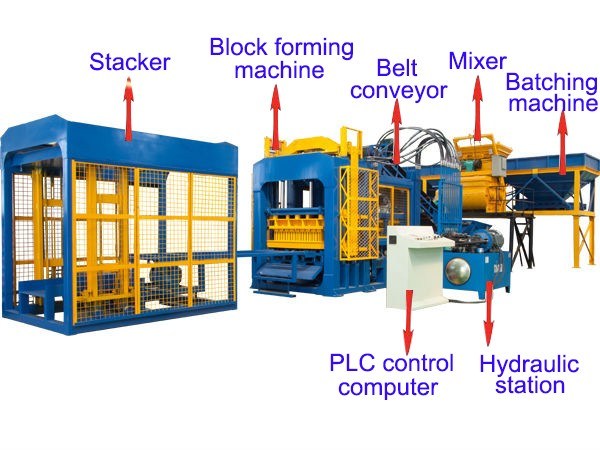

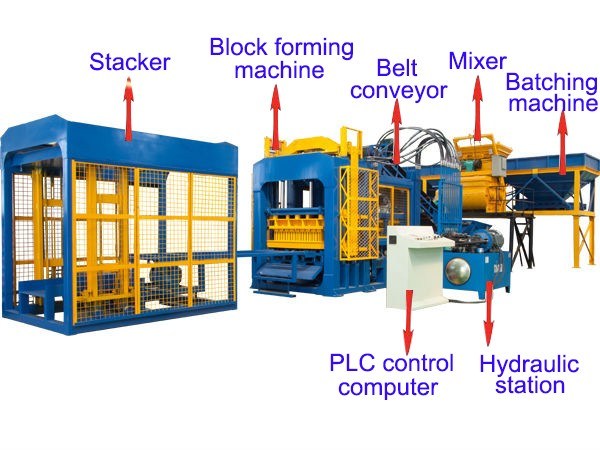

1.Introduction

QT10-15 automatic cement brick machine is a multi use machine, through the replacement of mold can produce different specifications of the porous brick, hollow brick, road edge stone, brick, grass planting brick, slope protection brick and other cement products. With the fabric device can produce color brick products.

QT10-15 automatic cement brick machine automatic diagnosis: random computer automatic fault diagnosis system, alarm, help in time troubleshooting. With the remote control system, through the telephone line connection, remote supervisory control,diagnosis.

QT10-15 automatic control system of cement brick machine: effective combination of digital and displacement sensingtechnology, so that the action is accurate and reliable, applicable to the complex work condition. The system collectedhundreds of production process to complete, advanced technology, simple operation.

2.Main Technical Parameters

Dimension of host machine | 3500x2220x2850mm | control style | PLC |

forming style | Hydraulic | Vibration force | 100KN |

vibrator style | table and mold vibrate together | raw material feeding style | 360 degree revolve |

forming height | 40-250mm | molding period | 15-20S |

molding area | 1025x810mm | size of pallet | 1350x900x30mm |

weight of host machine | 14ton | Mixer style | JS750 |

General water Consumption | 12T/day | Voltage | 220/240/380/440V |

Simple block machine line area needed |

Workshop | 200m2 |

Office | 100m2 |

Total area | About 2000m2 |

Worker arrangement |

operate | 1 | Material loader | 1 |

Drive forklift | 1 | Feeding pallets | 1 |

Maintain | 1 | Total | 5 |

4.Production capacity

Size(L x W x H) | Pcs /Mould | Pcs / Hr |

400X100X200 | 20 | 3000-3600 |

400X150X200 | 14 | 2100-2520 |

400X200X200 | 10 | 1500-1800 |

400X250X200 | 8 | 1200 |

3.Brick Raw Material

a. 8-10% cement, 30-40 % sand , 50-60% crushed stone.

b. 8-10% cement, 30% fly ash, 60% sand or stone powder

c. slag and cement

d. crushed construction waste, cement and sand

We supply different kinds of products. High quality and favorable price. We're pleased to get your Inquiry and we will reply you as soon as possible. We stick to the principle of " Quality first, service first, continuous improvement and innovation to meet the customers" For the management and " Zero defect, zero complaints" As the quality objective.