Product Specifications

| Prod Model: |

chemshun ceramics |

| Place Of Origin: |

Pingxiang Chemshun Plant,China |

| Materials: |

Alumina Ceramics |

| Alumina Conent: |

92% Al2O3 or 95% Al2O3 |

| Density: |

3.60g/cm3 or 3.70g/cm3 |

| Use For: |

as Wear Resistance Part for Protection Equipments |

| Application Method: |

Rubber Backed Ceramic, Lining Ceramic,Vulcanized C |

| Application Equipment: |

Hopper, Chute, Conveyer, Bunker, Concrete Storage |

| Application Industry: |

Mining Industry, Power Plant, Steel Plant,Cement P |

| Sample & Store: |

Available |

| Moh's: |

9 |

| Application: |

Wear Resistant |

| Corrosion Rate: |

0.001-0.01 |

Product Description

>>> Short description :

Chemshun weldable alumina ceramic tile liner is easy to install , widely used for materials conveying/handling/stocking abrasion resistance as hopper liner, cyclone linings, chute liner ,conveying pipe etc.

>>> Detailed description:

Anti-abrasion alumina ceramic products in the form of tile, liner and elbow are widely used in mining, chemical, steel making, port and cement industries to prevent wear, impact and corrosion of machinery. Chemshun ceramic liner tile can be custom made and installed in various types including adhesive, irregular-shape and assembly types,The main advantages of these products lie in their high level of strength, hardness, anti-abrasiveness and performance and these advantages contribute to the service life of the facility, savings in facility maintenance costs and uninterrupted operation for improved operational deficiencies as they protect your facilities at economic price.

>>> Product features:

> High hardness

> Superior abrasion resistance

> Corrosion and chemical resistance

> Light weight

> Can be applied in all kinds industrial abrasion solution field

1. Raw Material:

The wear resistance alumina ceramic products are made from the high purity, super fine and single narrow particle high-quality grain alumina powder, which is spray-dried processing, formed by cold isostatic pressing, firing on 1520 º C~1650 º C temperature. Subject to Al2O3 content difference, we have 92%, 95%, 97% and 99% abrasion resistance ceramics.

2. Advantage of the material:

High hardness Superior abrasion resistance Corrosion and chemical resistance Light weight Can be applied in all kinds industrial abrasion solution field

3. Application:

-Used to construct ceramic rubber plate as wear-and-impact-resistant lining.

-Used as Grinding Media for Ceramics, chemical, , mining, metallurgical, cement etc, in which low pollution to the grinding material is requested.

-Used as component of ceramic bearing.

4. Available Size:

| Alumina ceramic weldable tile popular Sizes (Length*width*thickness ) |

| 100*100*20mm (4"x4"x3/4") |

| 150*100*13mm (6"x4"x1/2") |

| 150*100*15mm (6"x4"x5/8") |

| 150*100*20mm (6"x4"x3/4") |

| 150*100*25mm (6"x4"x1") |

| 150*100*50mm (6"x4"x2") |

| 150*50*25mm (6"x4"x1") |

| 100*75*25mm (4"x3"x1") |

| 120*80*20mm |

| 228*114*25mm |

| 114*114*25mm |

More sizes and customized size acceptable.

Chemshun ceramics afford the relative weldable steel cone and ceramic rod. |

More products of chemshun ceramics size

6.Standard Shapes and Sizes

-Alumina Ceramic Plain Tiles

·150*100*6-50mm ( Length 150mm, Width:100mm, Thickness: 6-50mm) 150x100x6-50mm

·100*100*6-50mm ( Length 100mm, Width:100mm, Thickness: 6-50mm) 100x100x6-50mm

·120*80*6-50mm ( Length 120mm, Width:80mm, Thickness: 6-50mm) 120x80x6-50mm

·80*80*6-50mm ( Length 80mm, Width:80mm, Thickness: 6-50mm) 80x80x6-50mm

·50*50*6-50mm ( Length 50mm, Width:50mm, Thickness: 6-50mm) 50x50x6-50mm

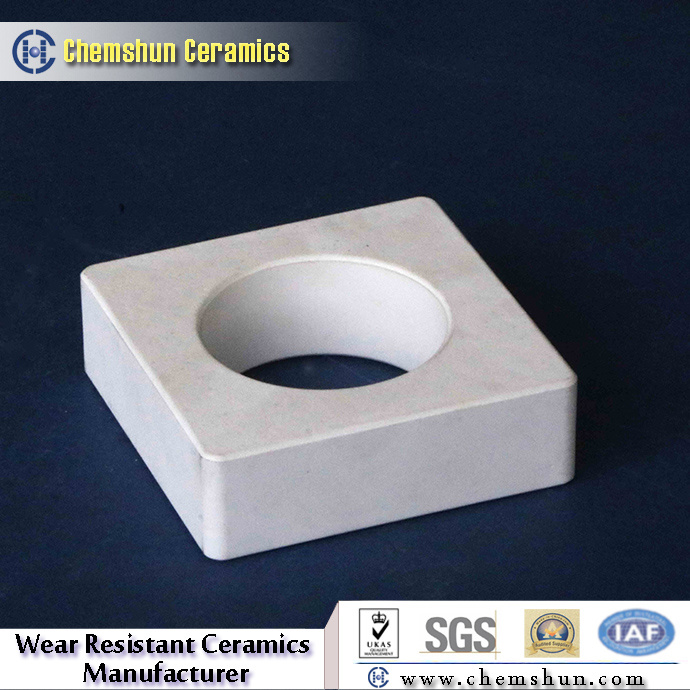

-Alumina Ceramic Weldable Tiles with center hole and ceramic plug and metal welding part

·150*100*12-50mm ( Length 150mm, Width:100mm, Thickness: 12-50mm) 150x100x12-50mm

·100*100*12-50mm ( Length 100mm, Width:100mm, Thickness: 12-50mm) 100x100x12-50mm

·120*80*12-50mm ( Length 120mm, Width:80mm, Thickness: 12-50mm) 120x80x12-50mm

·80*80*12-50mm ( Length 80mm, Width:80mm, Thickness: 12-50mm) 80x80x12-50mm

-Alumina Ceramic Hex Tiles (Hexagon Tiles)

·12*3-25mm (Side:12mm, Thickness: 3-25mm) 12x3-25mm

·19*3-25mm (Side:19mm, Thickness: 3-25mm) 19x3-25mm

·12*3-25mm (Side:12mm, Thickness: 3-25mm) 12x3-25mm on mesh backing (Ideal for concave or convex surfaces )

-Alumina Ceramic Small Tiles (Mosaic Tiles)

·10*10*2-10mm (Side: 10mm, Thickness: 2-10mm), 10x10x2-10mm

·17.5*17.5*3-15mm (Side: 17.5mm, Thickness: 3-15mm), 17.5x17.5x3-15mm

·20*20*2-15mm (Side: 20mm, Thickness: 2-15mm), 20x20x2-15mm

·33*33*4-25mm (Side: 20mm, Thickness: 4-25mm), 33x33x4-25mm

-Alumina Ceramic Dimplel Tiles (Bumps Tiles)

·20*20*4-10mm (Side: 20mm, Thickness: 4-10mm.Dimple Height: 1mm, Dimple: 5pcs) 20x20x4-10

·20*30*5-10mm (Side: 20mmx30mm, Thickness: 5-10mm.Dimple Height: 1mm, Dimple: 18pcs)

-Alumina Ceramic Cylinders (ceramic rod) Water polished

·20*20mm (Diameter: 20mm, Height: 20mm), 20x20mm with chamfer

·21*21mm (Diameter: 21mm, Height: 21mm), 21x21mm without chamfer

·31*31mm (Diameter: 31mm, Height: 31mm), 31x31mm with chamfer

·31*31mm (Diameter: 31mm, Height: 31mm), 31x31mm without chamfer

·32*31.5mm (Diameter: 32mm, Height: 31.5mm), 32x31.5mm with chamfer

-Alumina Ceramic Pipe Tiles (Ceramic Trapezoid Tiles Locking in Steel Pipe )

(Containing a wide variety of tapered side angles to fit virtually any size pipe)

·150*53/49.38*13mm (Length: 150mm Width: 53/49.38mm Thickness:13mm) 150x53/49.38x13mm

·150*53/49*25mm (Length: 150mm Width: 53/49mm Thickness:25mm) 150x53/49x25mm

·150*50/46*25mm (Length: 150mm Width: 50/46mm Thickness:25mm) 150x50/46x25mm

·100*35/32*13mm (Length: 100mm Width: 35/32mm Thickness:13mm) 100x35/32x13mm

·150*49.5/43.8*50mm (Length: 150mm Width: 49.5/43.8mmThickness:50mm) 150x49.5/43.8x50mm

-Alumina Ceramic Interlocking Tongue and Groove Tiles (Self-locking Tiles/Ceramic Block)

(Containing a wide variety of inside and outside widths to fit virtually any size batch or continuous ball mill)

·150*100*25mm (Length: 150mm Width: 100mm Thickness:25mm) 150x100x25mm

·40*40*40mm (Length: 40mm Width: 40mm Thickness:40mm) 40x40x40mm

·40*40*25mm (Length: 40mm Width: 40mm Thickness:25mm) 40x40x25mm

·30*30*25mm (Length: 30mm Width: 30mm Thickness:30mm) 30x30x25mm

-Alumina Ceramic Backing Rubber & Steel (Anti-wear & Resistant impact)

·500*500*20 ( Length: 500mm, Width: 500mm, Thickness:Ceramic:10mm Rubber: 5mm, Steel: 5mm)

·300*300*20 ( Length: 300mm, Width: 300mm, Thickness:Ceramic:10mm Rubber: 5mm, Steel: 5mm)

- Pre-Engineering Alumina Ceramics

- Alumina Bends

- Alumina Tube

- Alumina Plate

Technical Data Sheet(TDS)

| S.No. | Attributes | Unit | CHEMSHUN92 | CHEMSHUN95 |

| 1 | Alumin Content | % | 92 | 95 |

| 2 | Density | g/cc | 3.60 | 3.68 |

| 3 | Color | - | White | Pale Ivory |

| 4 | Water Absorption | % | 0 | 0 |

| 5 | Flexural Strength | Mpa | 280 | 300 |

| 6 | Moh's Density | Grade | 9 | 9 |

| 7 | Rock Well Hardness | HRA | 80 | 86 |

| 8 | Vickers Hardness(HV10) | Kg/mm2 | 1050 | 1190-1220 |

| 9 | Compressive strength | Mpa | 850 | 950-1000 |

| 10 | Thermal Expansion Coefficient

(25-1000 )oc | 1x10-6/ oc | 7.6 | 8.3 |

| 11 | Maximum operation temperature | oc | 1250 | 1250 |

Pingxiang Chemshun ceramics Co., Ltd is a manufacturer of 95% & 92% Al2O3 alumina and ZTA (Zirconia toughness Alumina) wear resistant ceramic liner products. Chemshun ceramics was established in 2002, we have 15 years of professional ceramic producing and import & exporting experierence. Chemshun have the products and service of: Design, produce, sell, as follows:

1) 95% Al2O3 Alumina, 92%Al2O3 alumina, ZTA, abrasion wear resistant ceramic liner / linings and high quality grinding beads and grinding balls.

Chemshun manufacturing wear resistance Ceramic liner including: Alumina ceramic plain tile, ceramic weldable plate, alumina pipe liner, ceramic blocks, abrasion resistant lining, lined pipe and fitting, ceramic linings, wear-resistance ceramic linings, chemshun pre-engineered equipment lined ceramics and paiting, custom designed alumina ceramic, hexagonal ceramics sheet, square ceramic lining pieces, ceramic liner, Ceramic Conveyor Pulley Lagging, ceramic tube and all kind of engineered ceramics, the finished equipment according to drawings. Ceramic Grinding balls, griding cylinders. Products used in the mineral, steel, power, port, cement, ceramic, glass etc industries, and was fixed on the equipment of chute, cyclone, cone, fan etc.

2)Catalyst support media /support covering materials (Inert ceramic balls, 99 alumina balls, all kind of ceramic/alumina rings) and all kinds of tower packings(Mat: Eramic/Plastic/Metallic), saddles, pall rings, flower rings, raschig rings, cascade mini rings etc) and ceramic honeycomb products.

Aim for servicing with the global maket, we established a new factory in 2008 which mainly supplys the high alumina wear resistant product and the high quality catalyst support media. In 2016year we establish a new producing line special for 99.5%Al2O3 and 99% Alumina balls.

Has strong research and production capability, with an annual production capacity of 5000 tons of wear-resistance product (grinding balls & lining bricks, alumina plate, alumina mosaic product), 1500m3 catatalyst support /covering materials (inert ceramic balls, 99alumina balls, ceramic honeycomb materials) and 1500m3 various chemical packing. We aim to serve clients from all over the world.