Product Specifications

| Prod Model: |

HBM |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

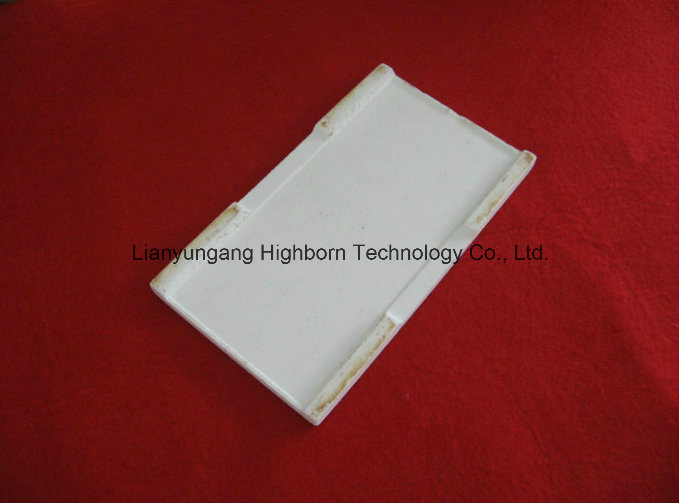

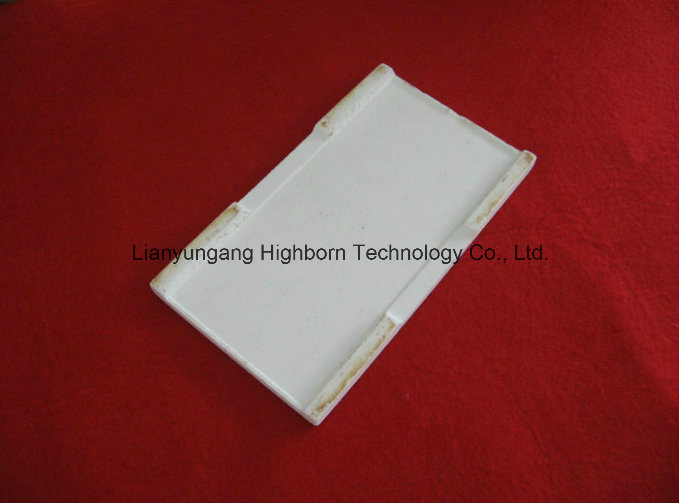

| Name: |

High Temperature Resistantwhite Corundum Mullite C |

| Size: |

Customized Is Ok |

| Color: |

White |

| Application: |

High Temperature Resistance |

| Working Temperature: |

1600c |

| Usage: |

Kiln Furniture |

| Keyword1: |

Corundum Mullite |

| Keyword2: |

Corundum Mullite Brick |

| Keyword3: |

Corundum Mullite Ceramic Brick |

| Keyword4: |

Refractory Ceramic Brick |

| Refractoriness (',℃): |

1770< Refractoriness< 2000 |

| Feature: |

Long Time Materials |

| Type: |

Refractory Material |

| Shape: |

Pipe |

| Material: |

MgO-Carbon Brick |

Product Description

Advantages:

1. Energy saving: 10-20%

2. Short warm-up time, free ovens, free sintering, use can be sent directly to electricity smelting.

3. High refractoriness, one turn induction coil pressed at bottom and the furnace volume is larger

than the traditional hand-made ones, high effective power, significantly improved the rate of melting furnace.

4. Quick and easy installation and removal

5.Furnace installation assembly, greatly improved labor productivity, effectively reducing the labor

intensity.

6. Improve the quality of liquid steel. The product has high refractoriness, good thermal stability,

resistance to high temperature erosion of liquid steel, greatly reduces the liquid steel slag.

7. Long service life: This product uses the optimal level of granularity and with high performance

composite materials, using pressure forming, so furnace life and stability is greatly improved.

8. Safe to use: the outside furnace layer (safety lining) may offer safety when failures happen,

effectively eliminating the accidents of wear ovens.

Magnesia crucible technical parameters:

Purity | 98% (Al2o3:2%) |

| Compressive strength | 1000Mpa |

| Bending strength | 300 Mpa |

| Moh's hardness | 5-6 |

| Max temperature | 2000°C |

| Density | 3.2g/cm3 |

| Service life | At1700 °C,you can use it for

more than 200 furnaces |

High magnesia crucible technical parameters

Purity | 99.9% |

| Compressive strength | 1800Mpa |

| Bending strength | 600 Mpa |

| Moh's hardness | 5-6 |

| Max temperature | 2200°C |

| Density | 3.5g/cm3 |

As a professional company in advanced ceramic industries, HIGHBORN is supplying high quality and high precision ceramic components for clients from worldwide. Our ceramic products are widely used in various fields of automotive, metallurgy, machinery, electronic & electrical, food, chemical, medical and so on. With experienced engineers and talented workers, we are able to evaluate projects and drawings properly, make valuable suggestion, supply satisfying products. Our materials including:

- Aluminium Oxide ( 95% 96% 99% 99.5% 99.7% Al2O3 )

- Zirconium Oxide ( Yttria stabilized ZrO2 )

- Silicon Nitride ( Gas pressure sintered & Hot pressed Si3N4 )

- Silicon Carbide (Reactive sintered, Pressureless sintered & Recrystallization SiC)

- Aluminum Nitride

- Machinable Glass Ceramic

Aiming at building long term cooperation relationship with our clients, we set our motto as "Quality First". Far now, our products have been exported to North Amirica, East Europe, West Europe, East Asia, Southeast Asia and get good reputation from our client.

Payment Term

T/T

L/C

D/A

D/P

AliExpress

Western Union

MoneyGram

According to certain countries, our way of payment will be adjusted.

Packaging : PE bag inside outer carton or wooden box,finally make the wooden pallet(950*950mm 950*1000mm) or according to your requirement

Shipping : delivery by express, by sea and by air so on.

HIGHBORN is one of the leading high quality quartz glass and precise ceramics manufacturer and supplier in China.

HIGHBORN has always been a defining force in the sale and fabrication of quartz glass within the semi-conductor, chemical, solar Energy and precise ceramics within semi-conductor, solar energy, textile, electronic, and laser industries.

Not only have we mastered the fabrication technology, our strength has always been based around listening to and understanding our customer's requirements and expectations.

Continuous improvement in all areas of our business is key to our grouth. What is equally important to us is maintaining in business, our inherent family values of trust, faimess and respect to our employees, suppliers and customers.