Product Specifications

| Prod Model: |

N52 |

| Tensile Strength: |

8.0kg/mm2 |

| Certification: |

RoHS, Rose, ISO9001:2008, ISO/Ts16949:2009:SGS |

| Coating Type: |

Zn, Cu, Au, Sliver, Epoxy, Ni-Cu-Ni,Nickel |

| Work Temp: |

80-220 Degree |

| Material: |

Rare Earth Permanent Magnet |

| Tolerance: |

+/-0.05mm |

| Delivery Time: |

Within 3-30 Working Days |

| Size: |

From 0.1mm to 200mm, Depend on Detail Dimension |

| Product Name: |

N40m Permanent Magnetic Segment NdFeB for Motor |

| Max Working Temp: |

80-230 |

| Application: |

Servomotor, Step Motor, DC Motor and Linear Motor |

| Shape: |

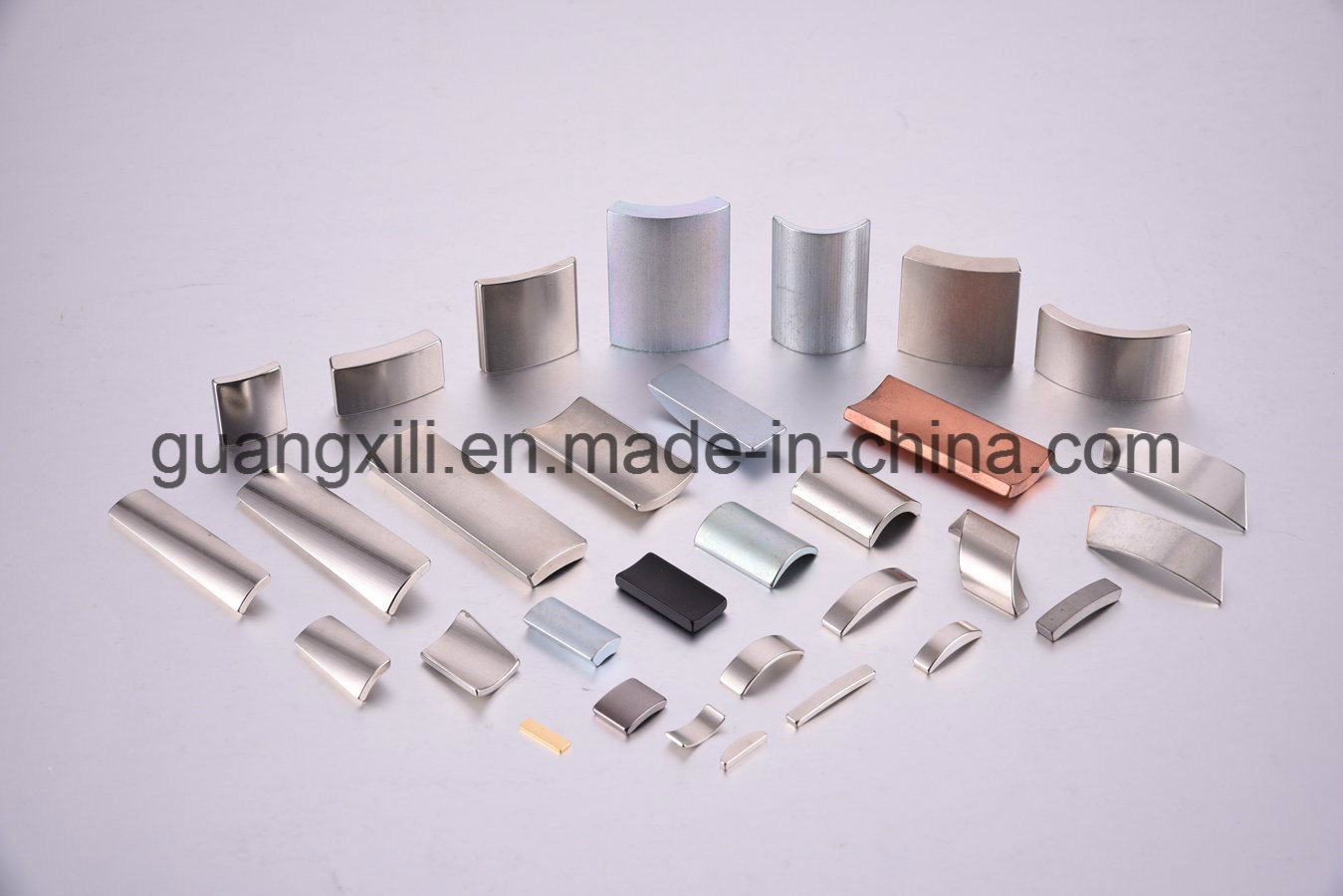

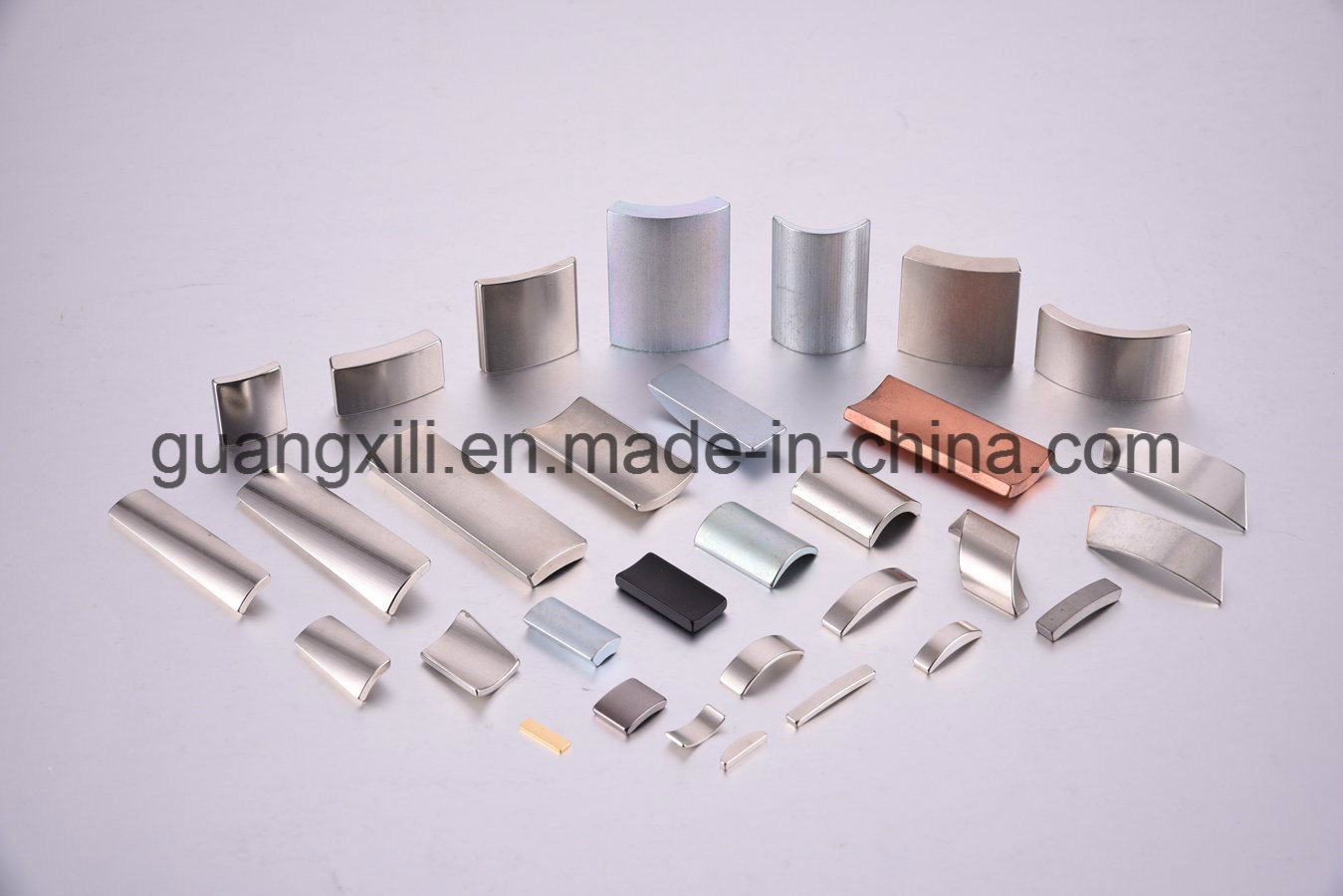

Ball. Bar, Block, Round, Square, Sheet, Ring, |

| Coating: |

Ni-Cu-Ni, Black Nickel, Zn, Sn, Au, AG, Black Epox |

| Grade: |

N40m |

Product Description

n52 magnetic of tile shape

We have the fixed Long-term cooperation factory. Which is mainly produce kinds magnet. We have invested much funds for some equipment, for example injection molding machine.

And Our technology is introduced from Japan and Germany. The major technical leader in our factory is from Japan and has been studying this field for over 15 years. Wish our best technology can solve your production problems.

A. Product Details

| Material | Neodymium-Iron-Boron |

| Working Temperature | Grade | Max. Operating Temperature |

| N35-N52 | 80°C (176°F) |

| 33M- 48M | 100°C (212°F) |

| 33H-48H | 120°C (248°F) |

| 30SH-45SH | 150°C (302°F) |

| 30UH-40UH | 180°C (356°F) |

| 28EH-38EH | 200°C (392°F) |

| 28AH-35AH | 220°C (428°F) |

| Magnet Shape | Disc, Cylinder, Block, Ring, Countersunk, Segment, Trapezoid, Irregular shapes and so on. |

| Magnet Coating | Ni-Cu-Ni, Nickel, Zn, Gold, Silver, Copper, Epoxy, Chemical, PTFE, Parylene, Everlube, Passivation and so on. |

| Technology Advantage | Depending on advanced R&D center, Quality control team and professional machining technicians, we can surpass our competitors in the stability of quality and superiority of property. |

| Delivery Advantage | The leadtime must be 2-5 days quicker than industry average because of more flexible machine process control. |

| Price Advantage | The price is 5-10% cheaper than industry average because of an excellent and efficient management system. |

| Application | Magnet neodymium are widely used in many fields, such as motors, sensors, microphones, wind turbines, wind generators, VCMs in hard disk drives, printer, switchboard, loudspeakers, magnetic separation, magnetic hooks, magnetic holder, magnetic chuck, common daily use, and so on. |

B. NdFeB Magnetic Parameter tableN35-N54; N35M-N52M; N33H-N50H, N30SH-N50SH; N30UH-N45UH,

N28EH-N40EH,N28AH-N35AH,N30SH-T-N45SH-T,N30UH-T-N42UH-T| | CGS Unit | SI Unit |

| Grade | Remanence

Br, KGS | Coercive Force

HcB, KOe | Intrinsic Coercivity

HcJ, kOe | Max Energy Magnetic

(BH)max,

MGsOe | Remanence Br, T | Coercive Force

HcB, kA/m | Intrinsic Coercivity HcJ, kA/m | Max Energy Magnetic (BH)max, kJ/m3 |

| N35 | 11.7 | - | 12.2 | ≥11.0 | ≥12.0 | 33 | - | 36 | 1.17 | - | 1.22 | ≥876 | ≥955 | 263 | - | 287 |

| N38 | 12.2 | - | 12.6 | ≥11.0 | ≥12.0 | 36 | - | 39 | 1.22 | - | 1.26 | ≥876 | ≥955 | 287 | - | 310 |

| N40 | 12.5 | - | 12.9 | ≥11.0 | ≥12.0 | 38 | - | 41 | 1.25 | - | 1.29 | ≥876 | ≥955 | 302 | - | 326 |

| N42 | 12.9 | - | 13.3 | ≥11.0 | ≥12.0 | 40 | - | 43 | 1.29 | - | 1.33 | ≥876 | ≥955 | 318 | - | 342 |

| N45 | 13.3 | - | 13.7 | ≥11.0 | ≥12.0 | 43 | - | 46 | 1.33 | - | 1.37 | ≥876 | ≥955 | 342 | - | 366 |

| N48 | 13.6 | - | 14.1 | ≥11.0 | ≥12.0 | 46 | - | 49 | 1.36 | - | 1.41 | ≥876 | ≥955 | 366 | - | 390 |

| N50 | 14.0 | - | 14.4 | ≥11.0 | ≥12.0 | 48 | - | 51 | 1.4 | - | 1.44 | ≥876 | ≥955 | 382 | - | 406 |

| N52 | 14.3 | - | 14.7 | ≥11.0 | ≥11.0 | 49 | - | 53 | 1.43 | - | 1.47 | ≥835 | ≥955 | 390 | - | 422 |

| N54 | 14.7 | - | 15.0 | ≥10.4 | ≥11.0 | 52 | - | 55 | 1.47 | - | 1.50 | ≥835 | ≥875 | 414 | - | 438 |

| N35M | 11.7 | - | 12.2 | ≥11.2 | ≥14.0 | 33 | - | 36 | 1.17 | - | 1.22 | ≥892 | ≥1114 | 263 | - | 287 |

| N38M | 12.2 | - | 12.6 | ≥11.4 | ≥14.0 | 36 | - | 39 | 1.22 | - | 1.26 | ≥907 | ≥1114 | 287 | - | 310 |

| N40M | 12.5 | - | 12.9 | ≥11.4 | ≥14.0 | 38 | - | 41 | 1.25 | - | 1.29 | ≥907 | ≥1114 | 302 | - | 326 |

| N42M | 12.9 | - | 13.3 | ≥11.4 | ≥14.0 | 40 | - | 43 | 1.29 | - | 1.33 | ≥907 | ≥1114 | 318 | - | 342 |

| N45M | 13.3 | - | 13.7 | ≥11.4 | ≥14.0 | 43 | - | 46 | 1.33 | - | 1.37 | ≥907 | ≥1114 | 342 | - | 366 |

| N48M | 13.6 | - | 14.1 | ≥11.4 | ≥14.0 | 46 | - | 49 | 1.36 | - | 1.41 | ≥907 | ≥1114 | 366 | - | 390 |

| N50M | 14.0 | - | 14.4 | ≥11.4 | ≥14.0 | 48 | - | 51 | 1.4 | - | 1.44 | ≥907 | ≥1114 | 382 | - | 406 |

| N52M | 14.3 | - | 14.8 | ≥11.4 | ≥14.0 | 50 | - | 53 | 1.43 | - | 1.48 | ≥907 | ≥1114 | 398 | - | 422 |

| N33H | 11.4 | - | 11.8 | ≥10.3 | ≥17.0 | 31 | - | 34 | 1.14 | - | 1.18 | ≥820 | ≥1353 | 247 | - | 271 |

| N35H | 11.7 | - | 12.2 | ≥10.8 | ≥17.0 | 33 | - | 36 | 1.17 | - | 1.22 | ≥860 | ≥1353 | 263 | - | 287 |

| N38H | 12.2 | - | 12.6 | ≥11.4 | ≥17.0 | 36 | - | 39 | 1.22 | - | 1.26 | ≥907 | ≥1353 | 287 | - | 310 |

| N40H | 12.5 | - | 12.9 | ≥11.4 | ≥17.0 | 38 | - | 41 | 1.25 | - | 1.29 | ≥907 | ≥1353 | 302 | - | 326 |

| N42H | 12.9 | - | 13.3 | ≥11.4 | ≥17.0 | 40 | - | 43 | 1.29 | - | 1.33 | ≥907 | ≥1353 | 318 | - | 342 |

| N45H | 13.3 | - | 13.7 | ≥11.4 | ≥17.0 | 43 | - | 46 | 1.33 | - | 1.37 | ≥907 | ≥1353 | 342 | - | 366 |

| N48H | 13.6 | - | 14.1 | ≥11.4 | ≥17.0 | 46 | - | 49 | 1.36 | - | 1.41 | ≥907 | ≥1353 | 366 | - | 390 |

| N50H | 14.0 | - | 14.4 | ≥11.4 | ≥16.0 | 48 | - | 51 | 1.4 | - | 1.44 | ≥907 | ≥1273 | 382 | - | 406 |

| N30SH | 10.8 | - | 11.4 | ≥10.1 | ≥20.0 | 28 | - | 31 | 1.08 | - | 1.14 | ≥804 | ≥1592 | 223 | - | 247 |

| N33SH | 11.4 | - | 11.8 | ≥10.3 | ≥20.0 | 31 | - | 34 | 1.14 | - | 1.18 | ≥820 | ≥1592 | 247 | - | 271 |

| N35SH | 11.7 | - | 12.2 | ≥10.8 | ≥20.0 | 33 | - | 36 | 1.17 | - | 1.22 | ≥860 | ≥1592 | 263 | - | 287 |

| N38SH | 12.2 | - | 12.6 | ≥11.4 | ≥20.0 | 36 | - | 39 | 1.22 | - | 1.26 | ≥907 | ≥1592 | 287 | - | 310 |

| N40SH | 12.5 | - | 12.9 | ≥11.4 | ≥20.0 | 38 | - | 41 | 1.25 | - | 1.29 | ≥907 | ≥1592 | 302 | - | 326 |

| N42SH | 12.9 | - | 13.3 | ≥11.4 | ≥20.0 | 40 | - | 43 | 1.29 | - | 1.33 | ≥907 | ≥1592 | 318 | - | 342 |

| N45SH | 13.3 | - | 13.7 | ≥11.4 | ≥20.0 | 43 | - | 46 | 1.33 | - | 1.37 | ≥907 | ≥1592 | 342 | - | 366 |

| N48SH | 13.6 | - | 14.1 | ≥11.4 | ≥19.0 | 46 | - | 49 | 1.36 | - | 1.41 | ≥907 | ≥1512 | 366 | - | 390 |

| N50SH | 13.9 | - | 14.3 | ≥11.4 | ≥19.0 | 48 | - | 51 | 1.39 | - | 1.43 | ≥907 | ≥1512 | 382 | - | 406 |

| N30UH | 10.8 | - | 11.4 | ≥10.1 | ≥25.0 | 28 | - | 31 | 1.08 | - | 1.14 | ≥804 | ≥1990 | 223 | - | 247 |

| N33UH | 11.4 | - | 11.8 | ≥10.3 | ≥25.0 | 31 | - | 34 | 1.14 | - | 1.18 | ≥820 | ≥1990 | 247 | - | 271 |

| N35UH | 11.7 | - | 12.2 | ≥10.8 | ≥25.0 | 33 | - | 36 | 1.17 | - | 1.22 | ≥860 | ≥1990 | 263 | - | 287 |

| N38UH | 12.2 | - | 12.6 | ≥11.4 | ≥25.0 | 36 | - | 39 | 1.22 | - | 1.26 | ≥907 | ≥1990 | 287 | - | 310 |

| N40UH | 12.5 | - | 12.9 | ≥11.4 | ≥25.0 | 38 | - | 41 | 1.25 | - | 1.29 | ≥907 | ≥1990 | 302 | - | 326 |

| N42UH | 12.8 | - | 13.2 | ≥11.4 | ≥25.0 | 40 | - | 43 | 1.28 | - | 1.32 | ≥907 | ≥1990 | 318 | - | 342 |

| N45UH | 13.2 | - | 13.6 | ≥11.4 | ≥25.0 | 43 | - | 46 | 1.32 | - | 1.36 | ≥907 | ≥1990 | 342 | - | 366 |

| N28EH | 10.4 | - | 10.8 | ≥9.8 | ≥30.0 | 26 | - | 29 | 1.04 | - | 1.08 | ≥780 | ≥2388 | 207 | - | 231 |

| N30EH | 10.8 | - | 11.4 | ≥10.1 | ≥30.0 | 28 | - | 31 | 1.08 | - | 1.14 | ≥804 | ≥2388 | 223 | - | 247 |

| N33EH | 11.4 | - | 11.8 | ≥10.3 | ≥30.0 | 31 | - | 34 | 1.14 | - | 1.18 | ≥820 | ≥2388 | 247 | - | 271 |

| N35EH | 11.7 | - | 12.2 | ≥10.8 | ≥30.0 | 33 | - | 36 | 1.17 | - | 1.22 | ≥860 | ≥2388 | 263 | - | 287 |

| N38EH | 12.2 | - | 12.6 | ≥11.5 | ≥30.0 | 36 | - | 39 | 1.22 | - | 1.26 | ≥915 | ≥2388 | 287 | - | 310 |

| N40EH | 12.5 | - | 12.9 | ≥11.5 | ≥28.0 | 38 | - | 41 | 1.25 | - | 1.29 | ≥915 | ≥2229 | 302 | - | 326 |

| N28AH | 10.4 | - | 11.0 | ≥9.8 | ≥34.0 | 26 | - | 29 | 1.04 | - | 1.10 | ≥780 | ≥2706 | 207 | - | 231 |

| N30AH | 10.8 | - | 11.4 | ≥9.8 | ≥34.0 | 28 | - | 31 | 1.08 | - | 1.14 | ≥780 | ≥2706 | 223 | - | 247 |

| N33AH | 11.4 | - | 11.8 | ≥9.8 | ≥34.0 | 31 | - | 34 | 1.14 | - | 1.18 | ≥780 | ≥2706 | 247 | - | 271 |

| N35AH | 11.7 | - | 12.2 | ≥9.8 | ≥34.0 | 33 | - | 36 | 1.17 | - | 1.22 | ≥780 | ≥2706 | 263 | - | 287 |

| N30SH-T | 10.8 | - | 11.4 | ≥10.1 | ≥23.0 | 28 | - | 30 | 1.08 | - | 1.14 | ≥804 | ≥1831 | 223 | - | 239 |

| N33SH-T | 11.4 | - | 11.8 | ≥10.3 | ≥23.0 | 30 | - | 33 | 1.14 | - | 1.18 | ≥820 | ≥1831 | 239 | - | 263 |

| N35SH-T | 11.7 | - | 12.2 | ≥10.8 | ≥23.0 | 33 | - | 36 | 1.17 | - | 1.22 | ≥860 | ≥1831 | 263 | - | 287 |

| N38SH-T | 12.2 | - | 12.6 | ≥11.4 | ≥23.0 | 36 | - | 38 | 1.22 | - | 1.26 | ≥907 | ≥1831 | 287 | - | 303 |

| N40SH-T | 12.5 | - | 12.9 | ≥11.4 | ≥23.0 | 38 | - | 40 | 1.25 | - | 1.29 | ≥907 | ≥1831 | 303 | - | 318 |

| N42SH-T | 12.9 | - | 13.3 | ≥11.4 | ≥23.0 | 40 | - | 42 | 1.29 | - | 1.33 | ≥907 | ≥1831 | 318 | - | 334 |

| N45SH-T | 13.3 | - | 13.7 | ≥11.4 | ≥23.0 | 42 | - | 45 | 1.33 | - | 1.37 | ≥907 | ≥1831 | 334 | - | 358 |

| N30UH-T | 10.8 | - | 11.4 | ≥10.1 | ≥27.0 | 28 | - | 30 | 1.08 | - | 1.14 | ≥804 | ≥2149 | 223 | - | 239 |

| N33UH-T | 11.4 | - | 11.7 | ≥10.3 | ≥27.0 | 30 | - | 33 | 1.14 | - | 1.17 | ≥820 | ≥2149 | 239 | - | 263 |

| N35UH-T | 11.7 | - | 12.2 | ≥10.8 | ≥27.0 | 33 | - | 36 | 1.17 | - | 1.22 | ≥860 | ≥2149 | 263 | - | 287 |

| N38UH-T | 12.2 | - | 12.6 | ≥11.4 | ≥27.0 | 36 | - | 38 | 1.22 | - | 1.26 | ≥907 | ≥2149 | 287 | - | 303 |

| N40UH-T | 12.5 | - | 12.9 | ≥11.4 | ≥27.0 | 38 | - | 40 | 1.25 | - | 1.29 | ≥907 | ≥2149 | 303 | - | 318 |

| N42UH-T | 12.8 | - | 13.2 | ≥11.4 | ≥27.0 | 40 | - | 42 | 1.28 | - | 1.32 | ≥907 | ≥2149 | 318 | - | 334 |

| 1). 1T=1KGs÷10;1KA/m=1KOe×79.6 ; 1kJ/m3 =1MGOe×7.96 |

| 2). For other grades and custom-made grades, please contact our Sales Department. |

C. Shape ShowDisc, Cylinder, Block, Ring, Countersunk, Segment, Trapezoid, Irregular shapes and more.

Customized shape are available.

D. Raw Material&Production Process

Raw materials mixing→Smelting →Powder Production→Molding→Sintering→Magnetic property testing→Fine machinery processing→Surface Coating→Finished Inspection→Magnetization and packing

F. Application

1) Servomotor, step motor, DC motor and linear motor

2) Loudspeaker, headphone, earphone and microphones

3) Holding system equipment

4) Medical facility

5) Sound device

6) Wind power

7) VCM, MRI

8) Mobile accessory

9) Research and development, as well as many other applications

G.Package

a: the weight is under 40Kg,we will choose FedEx,DHL or UPS with shielding box for you;

b: the weight is over 100Kg,we will choose shipping for you;

c: the weight is between 40Kg-100Kg per you request;

H.Test

FAQ

1. Q: What information do I need to supply when I have an inquiry?

A: If you have any inquiry, please kindly advise the following items:

Dimensions, sizes, shape and drawing with tolerances.

Material grade or magnetic properties.

Magnetic direction, quantity. Surface coating (if necessary).

2:Q: How about the quality of the magnets?

A:We can offer the certification of ISO14001,OHSAS18001.Our factory participate in the sub-project of the nations's 863 research project High performance sintered NdFeB magnets's production and application.

3. Q: What about the sample time and charge?

A: (1) 7-10 days if you want to customize your logo, charge according to your design

(2) 3-7 days for our existing samples for reference

4. Q: What about the delivery time of our products?

A: 10-15days.

Fast Delivery when you choose the item and decide your design, we can produce it as fast

as possible, and deliver it as quick and convenient as possible.

5. Q: Could you provide me the shortest lead time?

A: We have materials in our stock,if you really need, you can tell us and we will try our best to

satisfy you.

6. Q: What is your MOQ?

A: 1-10-100-500-1000-5000-10000-200000 pcs etc. depend different size ,item, design and process.

MIN and SMALL quantity accept accordingly.

7. Q: How to pay you?

A: T/T in advance(telegraphic transfer-bank order), for small order, or samples order, or shipment by air.

Western Union cash - for small order or samples order.

Other payment: L/C,D/A,D/P,MoneyGra,Paypal or Escrow.

Different areas may exist some differences.

8. Q: Could I pay a visit to your factory?

A: Yes, of course, if you need, we will help you visit our cooperative factory, everything will be well arranged.

9. Q: What about OEM and ODM?

A: OEM and ODM Accept. We have our best designers, we can produce any design you wanted to meet your needs.

10. Q: If I have more questions, where can I get the answer?

A: Any issue, please feel free to contact us any time.

Mobile:0086-13963975915

Tel: 0086 532-85196797

Fax: 0086 532-85196798

Qingdao Guangxili Industrial Products Co., Ltd. is a full-invested subsidiary company, affiliated with Japan HIKARI Group. Which is a comprehensive enterprise combining design, R&D, marketing and service. The branch is located in the beautiful West Coast Economic Zone, Qingdao city. The transportation is very convenient with QianWan port, Dongjiakou port, LiuTing airport and ShuGang expressway.

Since the establishment of company, we always adhere to the headquarters service concept of "Pioneering sprit, high responsibility, thanksgiving society". At the same improving the service quality continuously, we also build a strong team of technology, marketing and management. Relying on rigorous working attitude, competitive price, fast and steady supply coordination capacity, our product have been exported to Asia, Europe and America and other global dozens of countries and regions. And won the majority of customer support and trust, also enjoy a high reputation in the international market.

Our main products as follows: Magnet related products, storage cage, expansible aluminum gates, Kinds of fence and fittings, signboard, road& construction site safety products, rubber products, plastic products, wheel barrow, warehouse trucks, tool vehicles casters and so on. OEM and sample processing business also is acceptable. We try our best to create the characteristic product for clients.

In future, we will always offer excellent product and service with more advanced concept and sincere attitude.