Product Specifications

| Prod Model: |

SJSZ |

| Colour: |

Customizable |

| Electrical Parts: |

World's Famous Brand |

| Width Of Profile: |

50-500mm |

| Electrical Component: |

Schneider, Omron |

| Inverter: |

ABB Frequency Controller |

| Screw & Barrel: |

38crmoaia |

| Screw: |

Double-Screw |

| Automation: |

Automatic |

| Computerized: |

Computerized |

| Certification: |

ISO9001:2008 |

| Customized: |

Customized |

| Product Type: |

WPC |

Product Description

WPC WALL PANEL EXTRUSION PRODUCTION LINE

Product description

Specifications

pvc profile extrusion machine

1.for door and window profile,clapboards

2.PVC,PP,PE+Wood Fiber

3.CE,ISO

4.Warranty:1 year

Working flow

SJZ Series Conical Twin Screw Extruder→ Die mould → Vacuum Calibration Table → QYQ series Haul-offs and Cutting Machine Unite →DF series Stacker → Control cabinet

(Note: Other Auxiliary Machine, such as crusher, mixer, will be provided according to client's requirements)

Production Description:

PVC profile extrusion machine can produce all kinds of profile, for example, window, door and door frame, pallet, cladding of outdoor wall, faciliry of ourside park, floor etc. Output profile is Wood Plastic Composite(WPC) or Plastic UPVC. WPC Introduction:

As a new material to replace wood, wood plastic composite is widely used in fields of building decoration and outdoor building materials, such as edge and corner lines, fence of flowers nursery, skirting board, ceiling line, blind window, stair railing, decorative wall board, outdoor pavilion and so on. Most interior and exterior decorative building materials can be made by using wood plastic composite.

Particularly, wood plastic composite can be used in kitchen and washing room for its waterproof and fireproof functions which the raw wood does not have.

At present, wood plastic composite has already drawn extensive attention in the world and is praised as new material which will have board developing prospect.

Materials: PVC/PP/PE + Wood Powder or PVC, PE, PP.

Products

Extruder

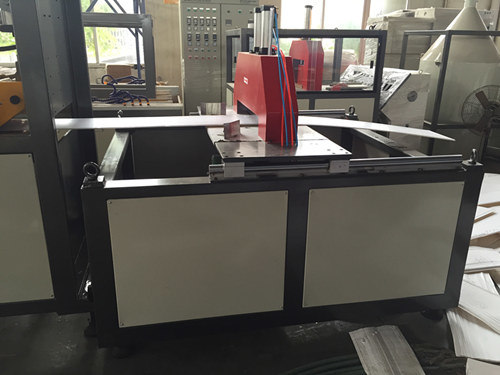

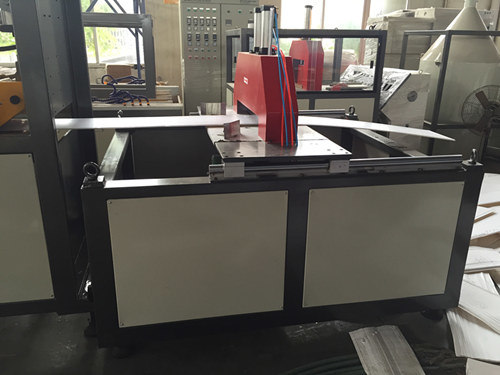

Mould

Haul - off

Cutter

Main technical parameters:

Extruder Type

| SJZ51/132

| SJZ55/110

| SJZ65/132

| SJZ80/156

| SJZ92/188

|

Main Motor Power

| 18.5kw

| 30kw

| 37kw

| 55kw

| 110Kw

|

Production capacity

| 80-120kg/h

| 100 -180kg /h

| 150-220kg/h

| 200-350kg/h

| 550-750kg/h

|

Main composition

Item | Quanlity |

SJSZ- XX Twin Screw Extruder with Automatic Feeding System | 1Set |

Die Mold & Stock Mold | 1Set |

Vacuum Calibrarion Table | 1Set |

Haul-off and Cutter Unit | 1Set |

Stacker | 1Set |

Electric Control System | 1Set |

We use good quality C model and U model steel as the frame, SIEMENS motor, SIEMENS contactor, OMRON tempertre controller, TTIANYI Button, ABB/FUJI/HOLIP/SHREADER inverter etc. electrical parts.

Choose us, closier to success.

Zhangjiagang city benk machinery Co., Ltd. is a committed in plastic extrusion solution and waste plastic recycling technology r & d, for customers to provide plastic extrusion, recycling & washing, granulation equipment as well as plastics extrusion molding of innovative enterprises.

Products with all kinds extrusion machine of plastic pipe, PVC profile, PVC imitation marble, construction & furniture foam board, and can provide customized solutions for customers of plastic extrusion. Washing mainly PE washing granulation, PE / PP film cleaning granulation. All kinds of production line is stable, competitive price, cost savings for the customer at the same time, in a stable and efficient performance to create value for customers, promote social resource conservation, sustainable development of ecological environmental protection.

As an excellent extrusion machine manufacturer, zhangjiagang benk machinery Co., Ltd is an expert on types of extrusion machine, who is known for its expertise and authority in extruder manufacturing and service. Benk has advanced technology, who is always ready to provide latest extruder ( product center) solution to your applications. After sale services is what makes benk extrusion machine differentiated with other manufacturers, besides its superior quality products. Benk extrusion machine has its own servicing team, consisting of experienced engineers and experts from related fields and skilled workers to make sure each of our clients can be served with 100% satisfaction.