Product Specifications

| Prod Model: |

QT8-15 |

| Brick Raw Material: |

Cement |

| Automatic: |

Yes |

| Capacity: |

12000PCS |

| Mixer: |

Js750 |

| Pallet Size: |

1010X550X30mm |

| Shipping Type: |

by Sea |

| Control System: |

PLC |

| Warranty: |

1 Year |

| After-Sales Service Provided: |

Engineers Available to Service Machinery Overseas |

| Condition: |

New |

Product Description

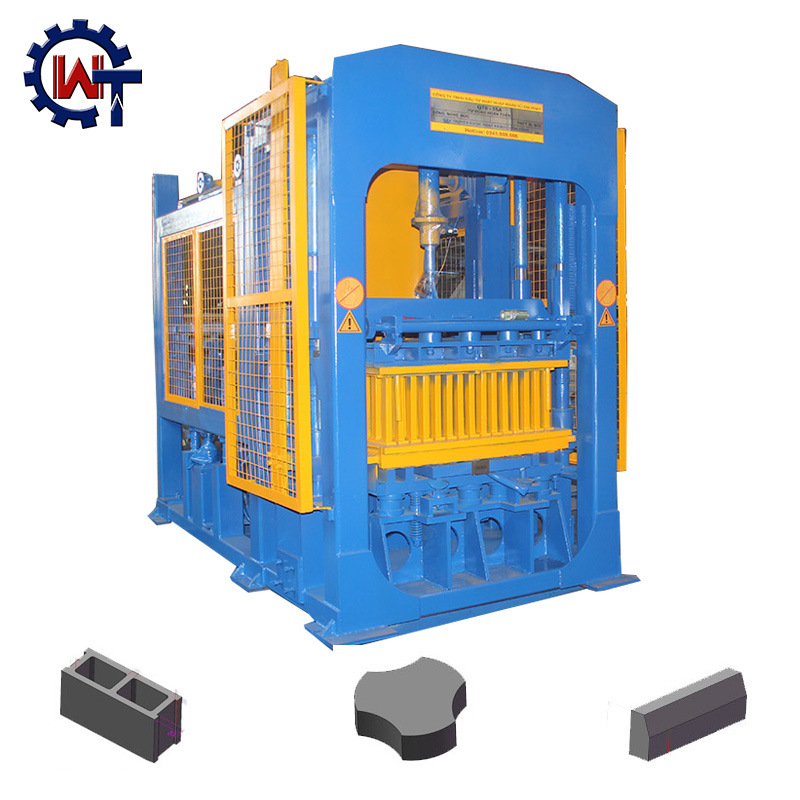

QT8-15 Hydraulic Pressure Method and Automatic fly ash brick making machine WORKING PRINCIPLE:

1.Material Batching and preparation Section: Raw materials are discharged to the mixer from three Hopper batching

machine, as there is a hole under ground. The mixed raw materials are sent to the mixer.

2.Mixing Section: After being mixed evenly with water, raw material are unloaded to the block making machine

through belt conveyor.

3.Block pressin Section: Mixed raw material are then sent to the mold case. Under PLC computer intelligent control.

Hydraulic transmission, vibration, shaping takes place.

4.Automatic Stacker Section:After demolding,green brick will be unloaded to the bamboo pallet.

5.Block Curing Section :Wet product will be conveyed through green block conveyor then to the stacker.

- Stacker(A)

- QT8-15 block moulding machine(B)

- PLC controller(simens/Mitsubishi)(C)

- Hydraulic station(D)

- JS750 Mixer(E)

- Cement scale(F)

- PLD1200 batching machine(G)

- Cement silo

- Screw conveyor

Main technical parameters | Dimension of main machine | 3000x2100x3090mm | Power of host machine | 35.1KW |

| Weight of host machine | 7.9T | Vibration force | 60-80KN |

| Molding area | 1080x800mm | Models of mixer | JS750 |

| Pallet size | 1300x900x30mm | Forming period | 15-20s |

| Water consumption | 5-6T | Workshop | 260m2 |

Theoretical Production capacity and block sample

| Size(L*W*H) | PCS/Mould | PCS/Hr | PCS/8Hr |

| 400x100x200mm | 15 | 2790 | 22320 |

| 400x150x200mm | 8 | 1530 | 12240 |

| 400x200x200mm | 7 | 1350 | 10800 |

| 400x250x200mm | 6 | 1170 | 8640 |

| 230x110x70mm | 32 | 5760 | 46080 |

| paver:200x100x60mm | 27 | 4860 | 38880 |

| Paver:200x163x60mm | 20 | 3600 | 28800 |

Our company

Our company Linyi Wante Machienry Co,.Ltd has long endeavoured to the research, production and sales of the block machines. We are constantly absorbing domestic and foreign advanced advanced technology and mature experience, after 20 years of unremitting efforts, it rapidly developed into the leading enterprises in the industry.

Our mainly products:Interlocking block machine,hydraform block machine, fully automatic block machine, Mobile brick machine, manual block machine, paver block machine and some related products like Mixer, Batching machine and Crushers, widely used in building construction field, road and bridge,energy and other areas.

The products have been exported to more than 100 countries and regions such as Africa, South Asia, Middle east, South America.used in building construction field, road and bridge,energy and other areas.

FAQ

1>.What's the payment terms?

30%T/T in advance,70% balance before delivery.

2>.How long it will takes before deliver?

usually it takes 25-30days,depends on quantity and voltage of motor.Delivery time on the sea to africa usually take 30-50 days.

3>.How long will my machine be warranted?

We supply one year quality warranty and send spare parts for free.If any quality problem,we will solve for free.

4>.Do you have engineer overseas ?

Yes.Our engineer can come to customers' place to help install the machine and train workers.Customer must pay for the air tickets and salary $60/day.

Linyi Wante Machinery Co., Ltd has long endeavoured to the research, production and sales of the stone coated roof tile and block making machine. There is the state-of-the-art equipment, superb technology and high standards of test base. The company has always been adhering to the "integrity, pragmatism, innovation, development" spirit of enterprise, constantly absorbing domestic and foreign advanced technology and mature experience, after 23 years of unremitting efforts, it rapidly developed into the leading enterprises in the industry.

Our mainly products: Stone coated mental roof tile, Aerated concrete production line, QT12-15 QT10-15 QT8-15 QT6-15 QT5-15 QT4-15 Fully automatic concrete block making machine and QT4-18 QT4-24 QT4-26 QT40-1 QT40-2 Simple concrete block making machine, hydraulic paver block machine, cement pipe machine, WT4-10 WT2-10 WT1-25 WT1-25D Clay interlocking brick making machine and WT1-20 WT1-20M WT2-20M Hydraform brick making machine, widely used in building materials, road and bridge, energy and other areas. Company as the foundation of the domestic market, focusing on the development of the international market, the products have been exported to more than 100 countries and regions, such as Africa, South America, Algeria, Nigeria, Tanzania, Vietnam, Fiji, Egypt, Canada, Russia, Kenya, Uganda, Iraq, Mozambique, Yemen, Thailand, Philippines, with frequent international business dealings and establish a good market reputation.

Our company has a perfect quality management system, and passed the ISO9001-2000 international quality management system certification. Besides, the company has established its own sales network in many countries around the world, and has set up sales branches and service outlets in major cities across the country. So we are able to provide our clients with timely, and convenient service.

The Linyi Wante Machinery Co., Ltd adhering to the brand philosophy that "excellence, do first-class products, creating a model for the industry", always adhere to enhance the brand ideology, building the brand quality, service, innovation, Positive enterprising, noble professionalism, drive the company forward to the first-class enterprise.

Contact Jojo ( 0086-539-8110558) for more information any time!