Product Specifications

| Prod Model: |

SHP-252 |

| Adhesive: |

Fire Rated Expoxy Resin |

| Fire Resistance: |

A Grade |

| Skin: |

Stone Veneer, Mable, Granite, Travertine, etc. |

| Surface Treatment: |

Brushed, Polished, Buffing, Burnishing, Flamed |

| Size: |

1800W by 3200L Max., Customized Made |

| Thickness: |

10mm, 15mm, 20mm, 25mm, 30mm or Customized Made |

| Stone: |

Marble, Granite, Travertine, Quart, Porcelain |

| Edge Processing: |

Edge Closed, Edge Open, 45 Degree Closed |

| Application: |

Facade,Cladding,Counter Top, Bathroom, Elevator |

| Frame Curtain Wall Kind: |

Mixed Frame |

| Metal Curtain Wall Kind: |

Aluminum Honeycomb Panel Curtain Wall |

| Usage: |

Partition; Facade; Couter Top; So on |

| Specila Function: |

Dry-Hanging Facade |

| Type: |

Stone Honeycomb Panel |

| Open: |

Edge Closed or Edge Open |

| Material: |

Granite,Marble, Aluminum Sheet |

| Glass Curtain Wall Kind: |

Stone Honeycomb Facade |

| Supporting Construction: |

Customized Made |

| Number Of Layers: |

High Rise |

| Shape: |

Flat, Wave, Curved, Customzied Made |

Product Description

Quartz honeycomb composite panel for wall decorationHONGZAN production lines & Capacity:| Aluminum honeycomb panels | 500,000 sqm annually |

| Aluminum honeycomb core &corrugated core | 4.5 million sqm annually |

| Stone (marble,granite) & Ceramic honeycomb panel | 80,000 sqm annually |

| FRP honeycomb panel | 100,000 sqm annually |

| Rock wool Sandwich panel | 100,000 sqm annually |

| Solid aluminum sheet | 300,0000 sqm annually |

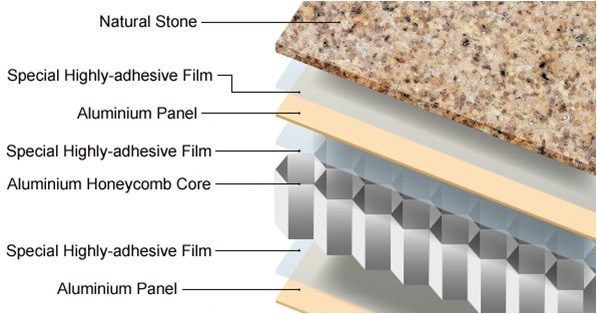

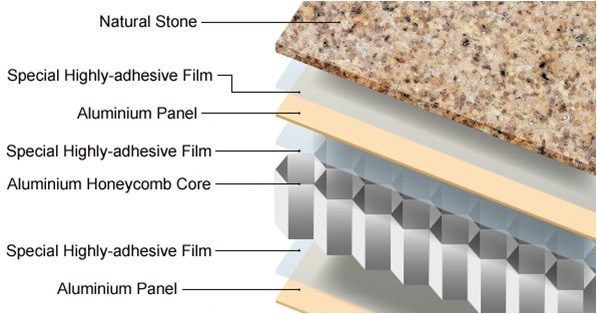

1. Product IntroductionBasic Information:Hongzan Stone Honeycomb Panel is a kind of high-tech products with natural granite and marble/granite or other stones and aluminum honeycomb panel. The panel remains the beauty of natural stone material and overcomes disadvantages of heavy, easy to break and brittleness of natural stone material. The outstanding advantages of stone honeycomb panel are low weight with strong strength, intensity, smoothness, sound and heat insulation and fire resistance, etc.

The stone honeycomb panel can be manufactured based on your specifications for a various applications, such as wall cladding (exterior & interior), bathroom and cleanroom, flooring, partition, elevator, door, counter top and other furniture boards, etc.

Structure of Stone Honeycomb Panel: Specification:*Marble Honeycomb Panel

Specification:*Marble Honeycomb Panel| Regular Size | Marble slab thickness: 3/5/8/10mm |

| Marble honeycomb panel size: 600*600/600*800/2440*1220*20mm |

| Max. Size | Marble slab thickness: 30mm |

| Marble honeycomb panel size: 2440*1800*30mm |

| Regular Surface Treatment | Brushed, polished, chiselled, honed, grooved, rubbing, etc. |

| Bending | Yes (customized) |

| Applications | Wall cladding(exterior & interior), ceiling, partitions, furniture board, elevator decoration, flooring, bathroom, etc. |

| Customerization(MTM) | Yes (color, surface texture, size, shape, pattern, etc.) |

*Granite Honeycomb Panel | Regular Size | Granite slab thickness: 5/8/10mm |

| Granite honeycomb panel size: 600*600/600*800/2440*1220*20mm |

| Max. Size | Granite slab thickness: 10mm |

| Granite honeycomb panel size: 1500*1200*30mm |

| Regular Surface Treatment | Brushed, polished, chiselled, honed, grooved, rough-rubbing, etc. |

| Bending | Yes (customized) |

| Applications | Wall cladding(exterior & interior), ceiling, partitions, furniture board, elevator decoration, flooring, bathroom, table, etc. |

| Customerization(MTM) | Yes (color, surface texture, size, shape, pattern, etc.) |

| Suggestion: | |

| 1. For interior wall : 15/20mm (stone: 5mm); mostly use marble & travertine; surface treatment: polished/matt surface |

| 2. For exterior wall:25/28/30mm (stone:8mm); mostly use granite & marble with dark color; surface treatment: polished/matt surface for marble |

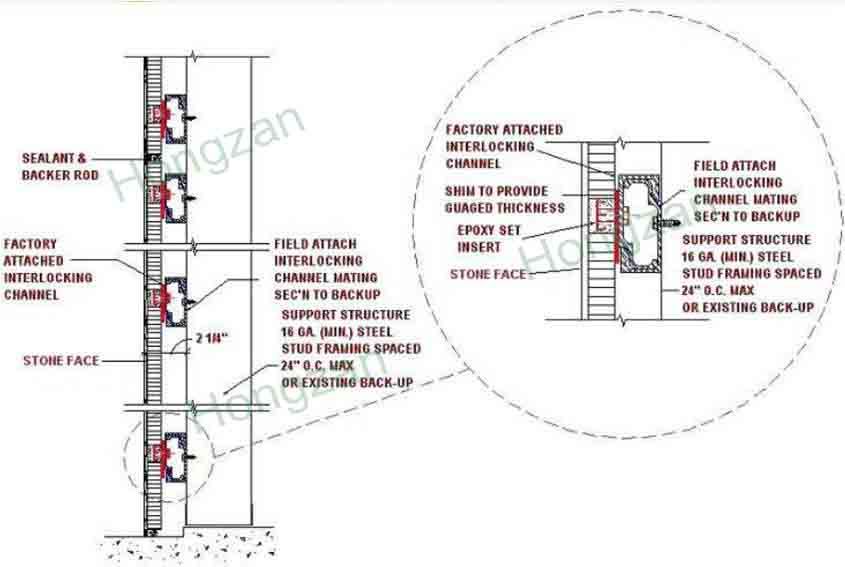

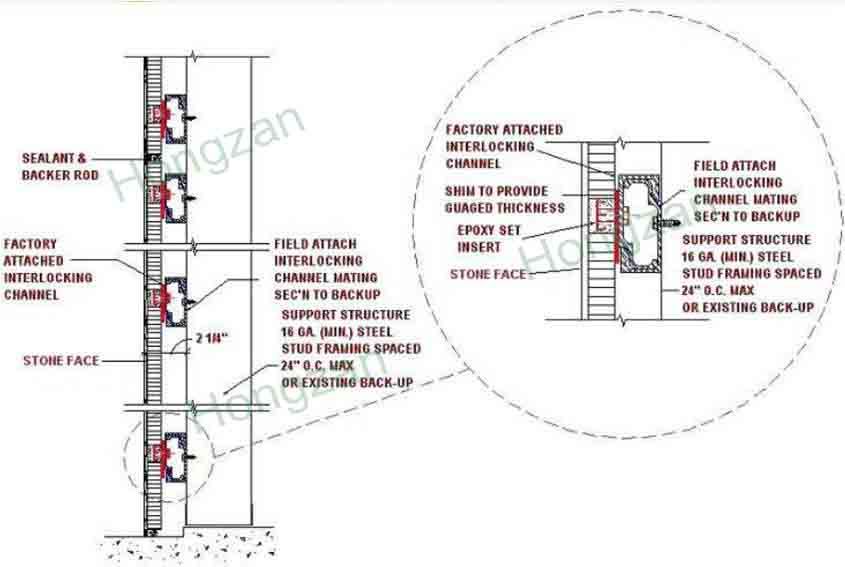

Hongzan Standard Installing System for Stone Honeycomb Panel (customized installation systems are available):

2. Technical Data*Executive standard for stone honeycomb panel: China Industry Standard "Stone Face Honeycomb Composite Panel for Building Decoration" JG/T 328-2011 Physical performance

2. Technical Data*Executive standard for stone honeycomb panel: China Industry Standard "Stone Face Honeycomb Composite Panel for Building Decoration" JG/T 328-2011 Physical performance | Items | Technical requirements |

| W | N |

| Contamination resistance | No visible residual contamination |

| Falling ball impact resistance | No glue-off or damage |

| Soft heavy object impact resistance | No glue-off or damage |

| Flatwise compressive strength/Mpa | ≥0.8 | ≥0.6 |

| Flatwise compressive elastic modulus/Mpa | ≥30 | ≥25 |

| Flatwise shear compressive/Mpa | ≥0.5 | ≥0.4 |

| Flatwise shear compressive/Mpa | ≥4.0 | ≥3.0 |

| Climbing drum peel strength (N.mm/mm) | Average value | ≥50 | ≥40 |

| Minimum value | ≥40 | ≥30 |

| Flatwise tensile adhesive strength Mpa | Average value | ≥1.0 | ≥0.6 |

| Minimum value | ≥0.6 | ≥0.4 |

| Flexural strength(standard value) Mpa | Granite | ≥8.0 | - |

| Sandstone,Marble,Limestone | ≥4.0 |

| Flexural rigidity (N.mm2) | Aluminum honeycomb panel | ≥1.0 x 109 | ≥1.0 x 108 |

| Steel honeycomb panel | ≥1.0 x 109 |

| FRP honeycomb panel | ≥1.5 x 108 |

| Shearing rigidity/N | ≥1.0 x 105 | ≥1.0 x 104 |

| Hot water resistance | Appearance | No abnormalities | - |

| Average decrease percentage of flatwise adhesive strength (%) | ≤ 15 |

| Temperature different resistance | Appearance | No abnormalities |

| Average decrease percentage of bending strength (%) | ≤ 20 |

| Anti-freezing | Appearance | No abnormalities |

| Average decrease percentage of flatwise adhesive strength (%) | ≤ 15 |

| Note: The width of the sample in flexural test is 100mm. |

*Comparison of Stone Honeycomb Panel and Traditional Stone Slab | | Traditional stone Slab With Junction Piece | Stone Honeycomb Panels |

|

| Weight comparison | 30mm Total thickness | 20mm Total thickness |

| 75kg/m2 (weight) | 15kg/m2 (weight) |

| Performance comparison | Unable to bend | Bendable(pressing 30mm bent not crack or broken) |

|

| Installation | big expenditure | small expanditure |

| ( >$50.00/m2 ) | ( <$16.00/m2 ) |

| Safety Performance | Cracking in impact-resistant test | Only with punctate cracking |

|

| Material availability (useful material output from one cubic) | 28-38m2 | 80-100m2 |

|

| Maximum size | ≤ 600 x 600 | up to 1600 x 3200 |

| |

3. Application & Factory ShowUltra-thin stone honeycomb panels can be used on wall cladding (exterior & interior), bathroom and cleanroom, flooring, partition, elevator decoration, door, counter top and other furniture boards, etc.

4. Package DetailsHongzan will use standard export packages--wooden crate which will largely protect the products well during land/sea/air/train transportation. Customized package requirements are available.

4. Package DetailsHongzan will use standard export packages--wooden crate which will largely protect the products well during land/sea/air/train transportation. Customized package requirements are available.

5. Project ShowStone Honeycomb Panel can be widely used on bathroom's wall, floor, counter top, exterior or interior wall cladding, flooring, elevator, partition, furniture board, table, cabinet top, etc.

5. Project ShowStone Honeycomb Panel can be widely used on bathroom's wall, floor, counter top, exterior or interior wall cladding, flooring, elevator, partition, furniture board, table, cabinet top, etc.

6. Contact DetailsVictoria

Mobile/whatsapp/IMO: 0086 139 2319 2421

Tel: 0086-757-85622688

Fax: 0086-757-85650560

History: Established in 2002. It is one of the leading manufacturers of metal and stone honeycomb panels, honeycomb cores products in China.

Location & Factory scale: Located in Nanhai district, Foshan City, Guangdong, China; The factory covers an area of about 30000 square meters and be equipped with 300 sets of large-scale specialized production equipment.

HR and R&D: More than 300 workers and 10 experienced engineers.

Main Production lines cover: Aluminum honeycomb panel, aluminum honeycomb core, stone(marble, granite) honeycomb panel, ceramic honeycomb panel, stainless steel honeycomb panel, Formica honeycomb panel, Corrugated panel for curtain wall, partition, ceiling, vehicles,

Quality Control & Test: QA quality assurance system and BV, TUV, SGS product test

Obtained Certificates:

1) ISO 9001: 2008 certificate

2) ISO 9001: 14001 Environment Management System certification

3) BS 476 475 by TUV, Singapore

4) EC TYPE EXAMINATION (MODULE B) CERTIFICATE FOR MARINE INDUSTRY BY LLOYD'S

5) AAA enterprise of quality & green building material products

6) Member of the Building Decoration Association of China

7 SGS testing reports and quality control certificates

8) and some other test reports for the products.

What we can do for you:

We are not only supply excellent products with high quality at competitive prices, but also provide excellent engineering solutions, efficient & workable R&D support throughout your projects with our experienced rigorous engineers and trained workers, as well as high quality services are provided always.

Objectives: With our excellent high quality products and services, efficient reaction, competitive price and rigorous professional R&D support, uttermost to satisfy our global customers at every aspect!

Company Culture: Honesty, Hardworking, Teamwork, Curiousness, Pleasure, Thankfulness, Pioneering and Enterprising.

We will always persist our faith and keep perfecting!