Product Specifications

| Prod Model: |

brick machine |

| Method: |

Hydraulic Pressure |

Product Description

Brick setting machine introduction

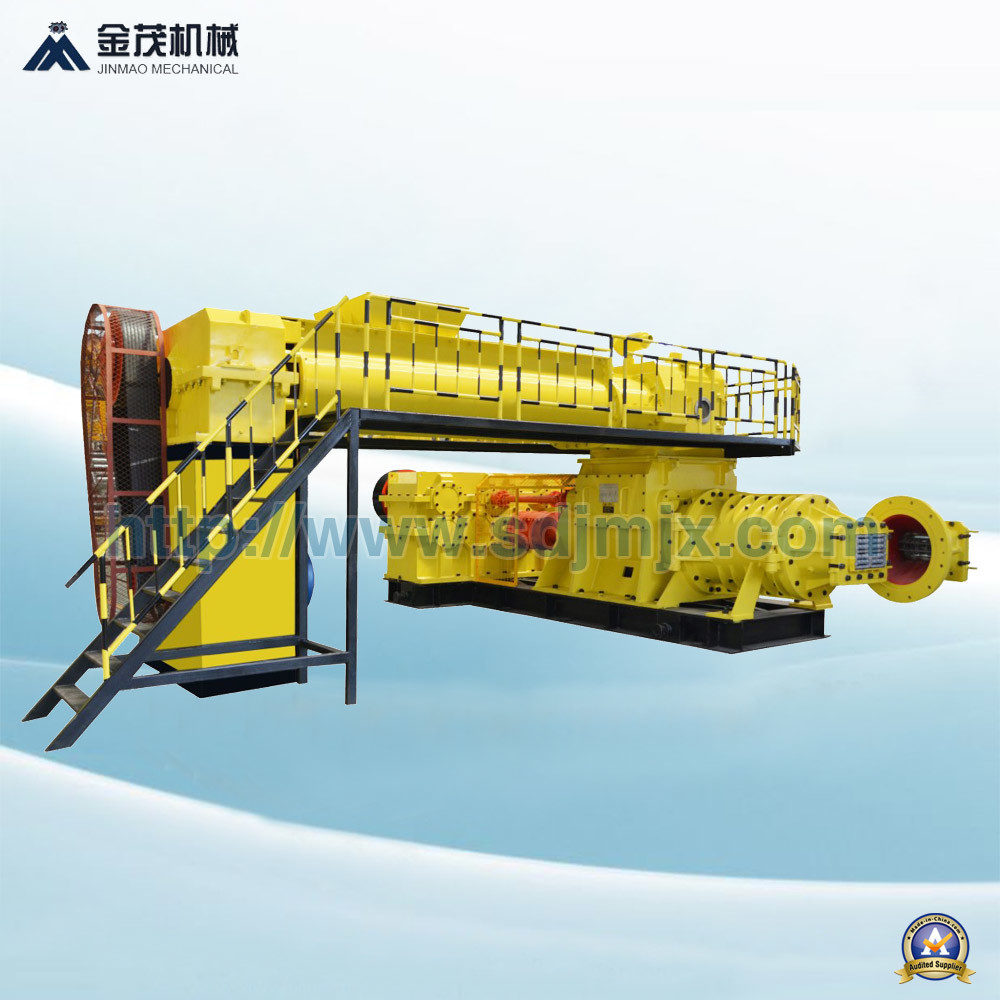

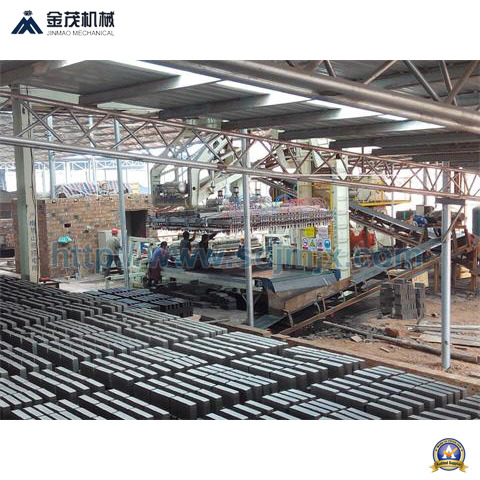

Auto green brick setting system is mainly suitable for bricks stacking in the once or twice firing tunnel kiln. The machine adopts the

advanced PLC central control. Frequency conversion controls the rotating, hydraulic controls the lifting-falling clamps, and digital

technique controls the brick separating. With the advantage of energy saving, efficiency maintence, low cost and stable operation, it keeps

the developed standard in the front rank internationally.

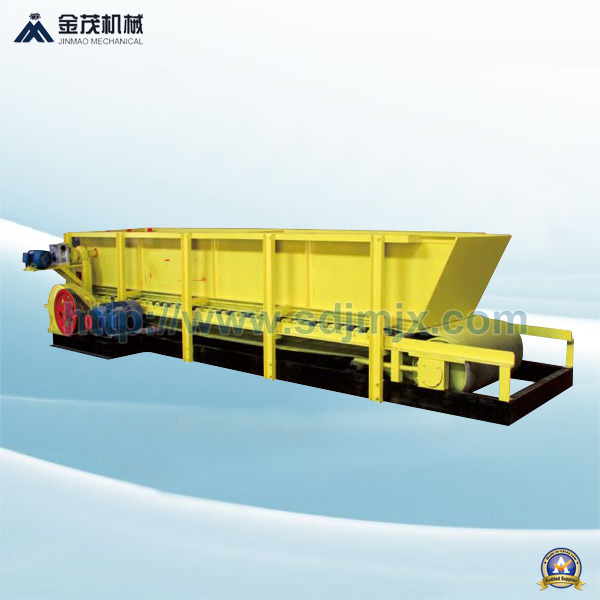

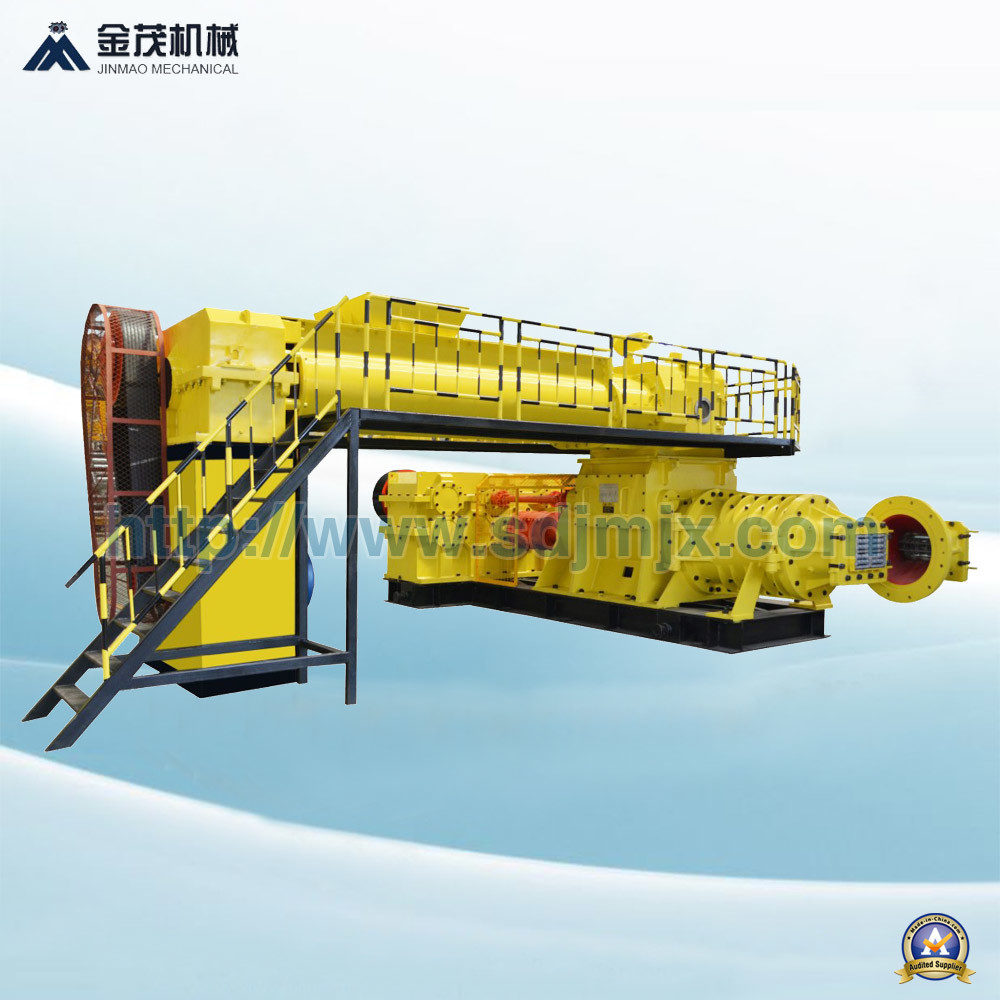

The full-automatic brick setting machine(ZMP)mainly applies to brickstacking in the once or twice firing tunnel kiln. It is controlled by

the electricity and hydraulic lift, it has the characters of energy saving, efficiency,easy maintenance, low cost and stable operation.

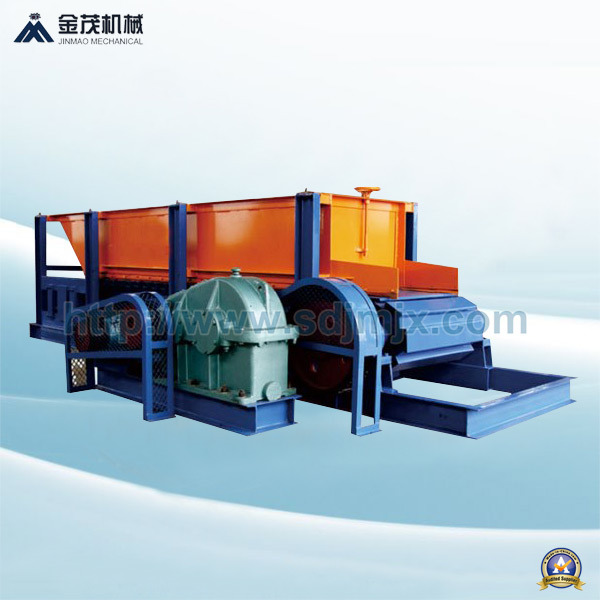

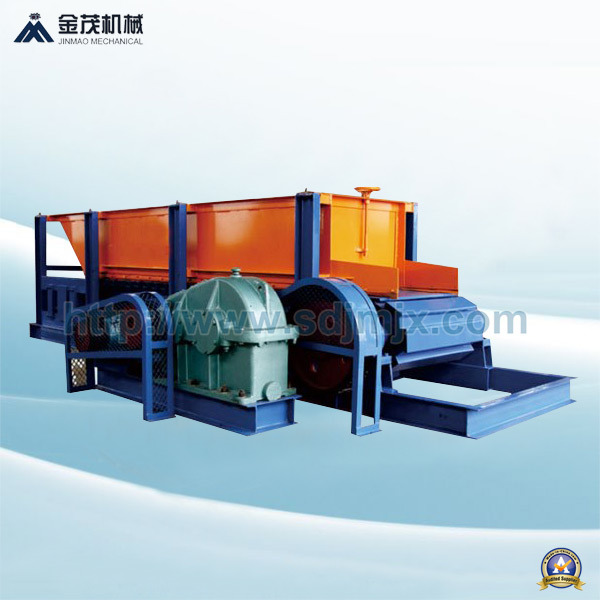

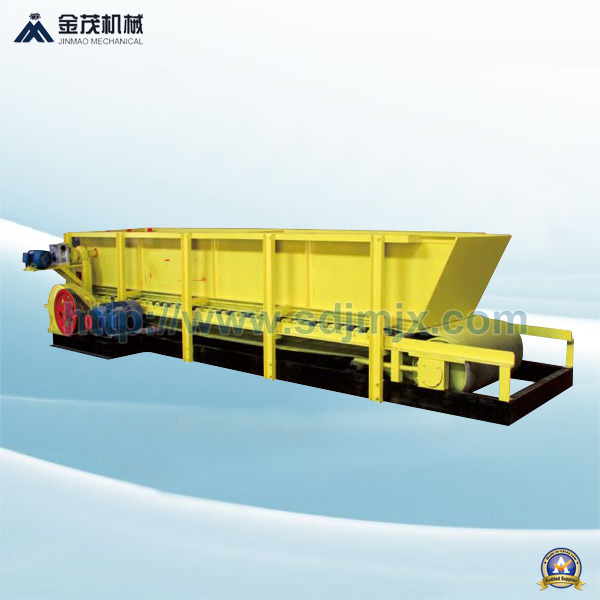

The full-automatic brick setting machine is formed by moving trestle, clamp plate, separator, lifting guide pillar, rail, hydraulic system

and electrical system, etc.

The workflow of hydraulic brick setting machine: when the cutter pushes the green bricks to the separating board, the separator starts work, it

drives the separating board stretch and separate the bricks. When the brick separating is finished, the lift cylinder turns down. When the clamp

plate reaches the pre-set location, the clamp plate fixture picks up the bricks, and then it is lifted to apredetermined height by the lifting cylinder.

After all those progress,the separator opens the air duct and the moving device drives brick stacking machine to the top of the kiln car,

The kiln car rotates 90oand then lift cylinder drops down to a predetermined height for setting bricks, the clamp plate opens and lays the bricks on

the kiln car, it completes stacking process automatically. With the periodical operation the whole stacking work is finished, all these functions are

centralized controlled automatically.

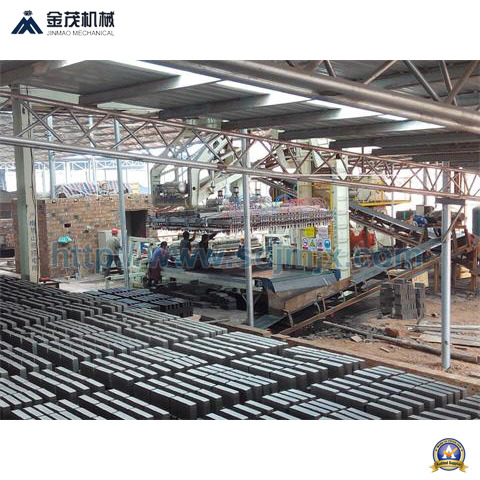

Jinmao Mechanical Co., Ltd is a high-tech enterprise in brick making machinery field, which integrating R&D, manufacture and trading. Our company has JINMAO brand, dozens of specifications for brick machinery.

Our main products are: Auto setting machine / auto brick cutter / robot stacking system/ blank cutting and slicing machine.

Now we have built more than 500 brick production line in China and we also have sold auto brick making machine to more than 30 countries, like India, Bangladesh, Indonesia, Myanmar, Kazakhstan, Uzbekistan, Turkmenistan, South Africa, Uganda, Peru, Brazil, Iraq, Bolivia, Mexico, etc. Our products sells well both in the domestic market and abroad and enjoys a good reputation.

Our company not only provides customers with various brick making equipment, but also provides services including process design, kiln design, workshop design and project contract. In addition, we have a professional team of engineers to offer the best after-sales services, such as training workers, imparting technical Instruction and fixing problems.

We clearly know that only the completely perfect quality and service are the best. We are always trying to be the best all the time. We are willing to make our progress with you hand in hand and become the high-class enterprise with non-stop efforts. Anyway, choosing to cooperate with us is really your wise choice. Hope to cooperate with you sincerely.

Company culture

Company spirit: Advance with the time, vie for the first place, be people-oriented, seek technological innovation.

Our objective: To develop green energy-saving buildings, create high-quality green energy energy-saving products, and build a green energy enterprise.

Company values: From the society, and for the society.

Our philosophy:

Market-oriented: Customer centric;

Quality centered: Innovation-based development;

Corporate tenet:

Go all out to create values for customers; Ultimate integrity, win-win situation, equality of responsibility and values; Pursuit of excellence, work harder everyday

Management concept: System-based, science-based, and people-centered.

Talent concept: Everyone is a talent; Talents are identified through real performances rather than superficial judgement.

Quality concept: Quality is tested through practice, and judged by users.

Our motto: Love is the magnet that attract people; Resilience is the key to success.

Professional ethics: Honest management, fair competition.

Safety concept: Care for life; Safety is of ultimate importance.