Product Specifications

| Prod Model: |

BBS-1 |

| Name: |

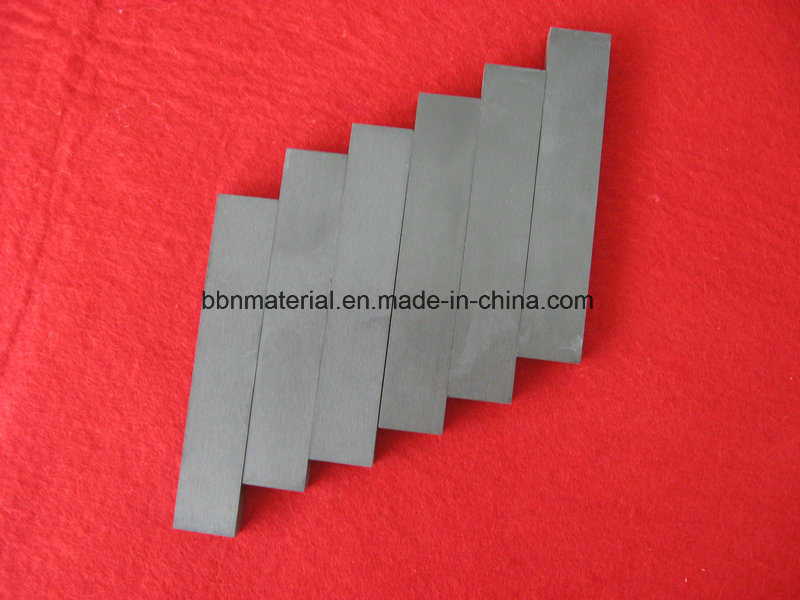

Silicon Nitride Ceramic Square Block Brick |

| Color: |

Black/Gray |

| Compressive Strength: |

2200 MPa |

| Water Absorption: |

0% |

| Max. Working Temperature: |

1550°c |

| Flexural Strength: |

650 MPa |

| Density: |

≥3.2g/cm3 |

| Fracture Toughness: |

6.2MPa.M1/2 |

| Coefficient Of Thermal Expansion: |

3.0~3.2 X 10-6/ºC |

| Vickers Hardness: |

1500MPa |

Product Description

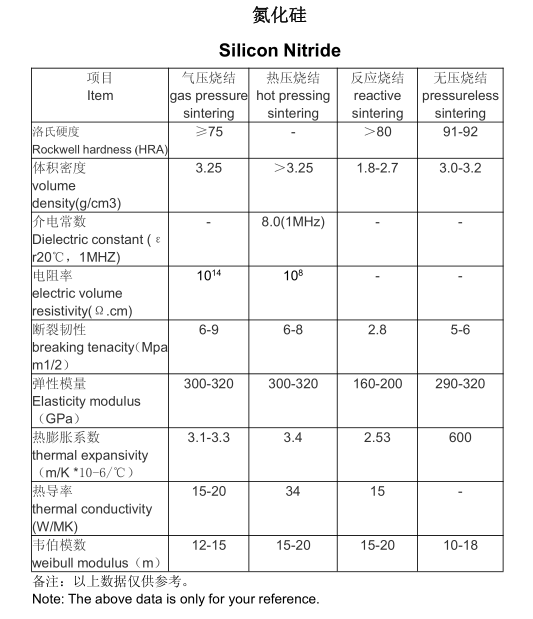

Silicon Nitride Ceramic Square Block BrickProduct DescriptionMaterial Introduction:

Silicon Nitride (Si3N4) is a widely used ceramic material in high temperature application, it has high strength in both room temperature and high temperature condition, the strength of silicon nitride can be kept up to 1200ºC; the low coefficient of thermal expansion make it a ceramic material possessing excellent thermal shock resistance; at the same time, it also has good thermal conductivity.

Except for the excellent properties in thermal application, silicon nitride also has good mechanical, chemical, electrical properties. It has good strength, good flexture strength and wear resistance;it is a good performance electrical insulation ceramic material; it is corrosive against all inorganic acid, most of organic acid solutions and some of caustic soda solutions.

Main Features:

*High strength over a wide temperature range

*High fracture toughness

*High hardness

*Outstanding wear resistance, both impingement and frictional modes

*Good thermal shock resistance

*Good chemical resistanceDetailed Images

Name: Silicon Nitride Ceramic Square Block Brick

Name: Silicon Nitride Ceramic Square Block Brick

Brand: Baibo

Original: ChinaAdvantages1. Moulding: Cold isostatic pressing(CIP)2. Sintering: GPSN/HPSN3. High strength and good compactness4. Low thermal expansion coefficient5. Excellent thermal shock resistance6. No wetting by molten aluminum and non-ferrous metal7. Good corrosion resistanceOur CompanyBaibo is a modern enterprise management company, who devote themselves to the service of product research and development, construction and maintenance.

Our company has a long history. We own the advanced equipment, a young, energetic, proficient and experienced team of professionals which with leading technology strength, excellent operational management and high-quality services what made us be recognized by customers of the chemical, petroleum, electric power, metallurgy, building material, aerospace, machinery and other industries.Our Service- Customize components

- Rapid production of samples

- Rapid design of mould

- Rapid mass production

- OEM, ODM and OBM are acceptable

- Instant technical support

- Quickest reply onlinePacking & Delivery Packaged by polybay and bubble bag in the stardard export carton,

Every package can be offered with English installation instruction.

FAQ

1.What is your payment term?

We mainly accept T/T, West Union, Credit card and L/C.

Paypal will be available in the near future.

2.Where is your main market?

We have been exported to USA, Korea, UK, France, Russia, Germany, India, Spain, Brazil etc, so far, there is about 94 countries we have been exported, we also get good reputation from our customers.

3.For alumina ceramic, what about the forming method?

Drying pressing

Isostatic pressing

Hot pressing casting

4.What about the package?

We pack with plastic bubble paper, carton box, then safe wooden box outside, we can control the breakage less than 1%.

5.Do you support OEM?

Sure! We offer OEM for many customers all over the world.