Product Specifications

| Prod Model: |

DB-TCM-I, DB-TCM-II, DB-TCM-III |

| Ceramic Shape: |

Cylindrical,Hexagonal & Rectangular |

| Ceramic Size: |

Variuos Size & Thickness |

| Product Material: |

95+/-1% |

| Ceramic Hardness: |

Mohs9 |

| Rubber: |

Nr |

| Peel Strength: |

>800n/Cm |

| Steel Mild Plate: |

Q235A |

| Certificate: |

ISO9001:2008,SGS |

| Application: |

Hopper,Chutes,Bins,Lining Pipe,Side Bar,Deck Plate |

| Feature: |

Cold-resistant |

| Material: |

High Alumina Ceramic and Rubber |

| Usage: |

Material Handling Industry |

| Raw Materials: |

92% Alumina Ceramic, Rubber, Steel |

| Medium: |

Ceramic Tile in Rubber |

| Performance: |

Wear Resistance |

Product Description

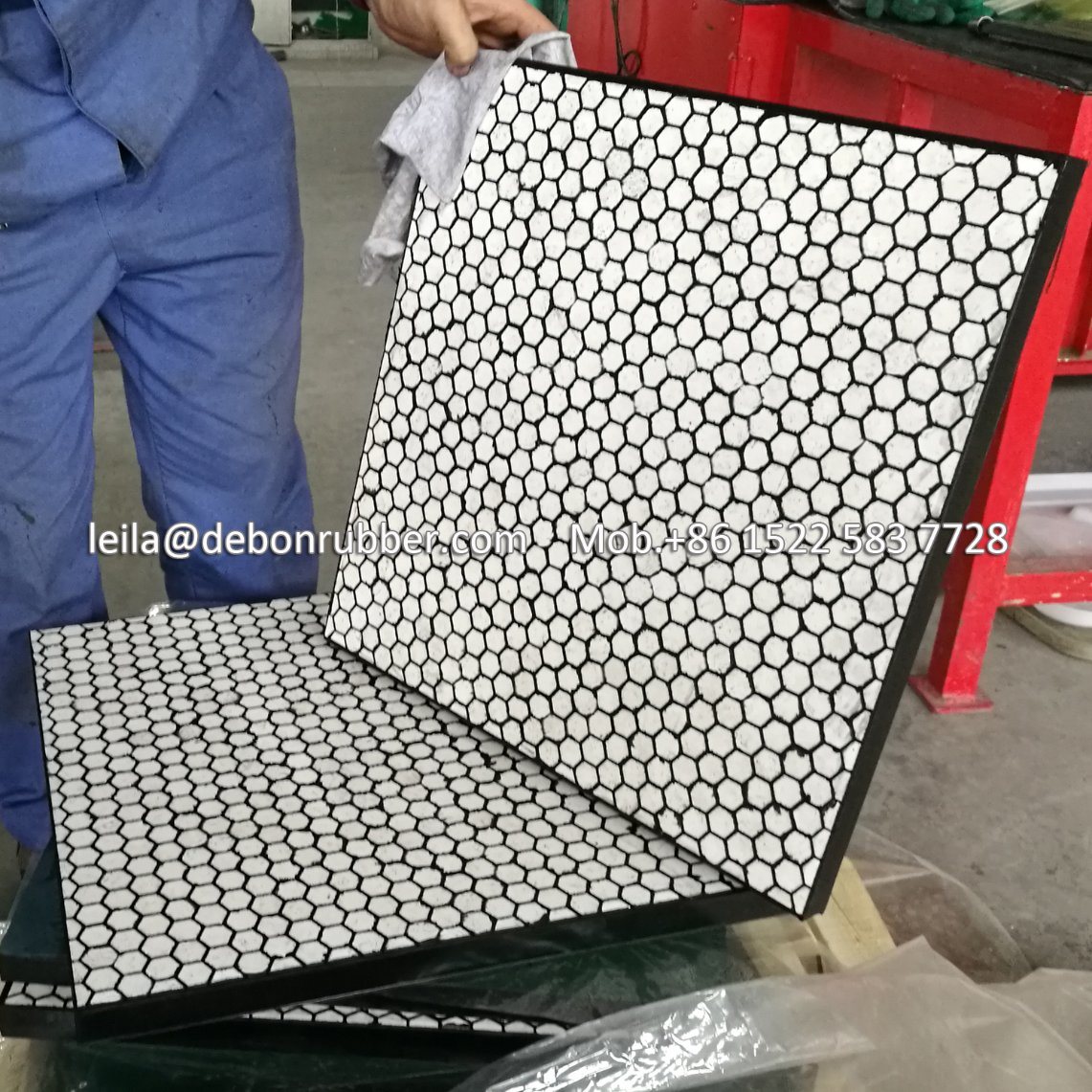

Wear and Abrasion Resistant Rubber Ceramic Tile Mats

Features of rubber backed ceramic mats:

1. combine energy absorbing rubber and excellent abrasion resistant high alumina ceramic, suitable for high wear and impact applications.

2. custom shapes and sizes to meest your specific requirements, standard liners and non-standard ones are all available.

3. complete wear and abrasion solutions

4. manufacturer with rich experience, good bond between rubber and ceramic, ceramics stay in place until completely worn.

5. wide range of rubber ceramic mats to meet your different requirements.

Product Description:

High wear resistant rubber backed ceramic tile mats are embedding high alumina ceramic into energy absorbing rubber or urethane cushion, and bond both to steel backing plate via hot vulcanizing for easy installation.

Impact-absorbing rubber cushions helps reduce impact energy and prevent ceramic tiles breakage,

Steel backing plate with studs for easy installation.

Application:

High wear resistant rubber ceramic liners are suitable for applications in areas of severe impact and areas of high abrasion.

High alumina ceramic deliver extra abrasion resistance and extend wear life.

High alumina ceramic:

1. Aluminium Oxide: al2o3>92%

2.Specific gravity of ceramic 3.6 g/cm3

3.Hardness(Moh's) > 9 t

Applications of rubber ceramic chute ceramic liner:

* conveyor chutes

* reflectors and impact plate

* bins, hoppers

*conveyor skirt liners

* stackers and reclaimers

TCM chute wear protection rubber ceramic liner:

We specialize in manufacturing alumina ceramic wear liners, experience makes sure high quality, advanced technology, excellent bonding strength.

Our rubber alumina ceramic liners have been exported to many countries, high quality have been approved.

Abrasion resistant rubber ceramic wear liner selection chart:

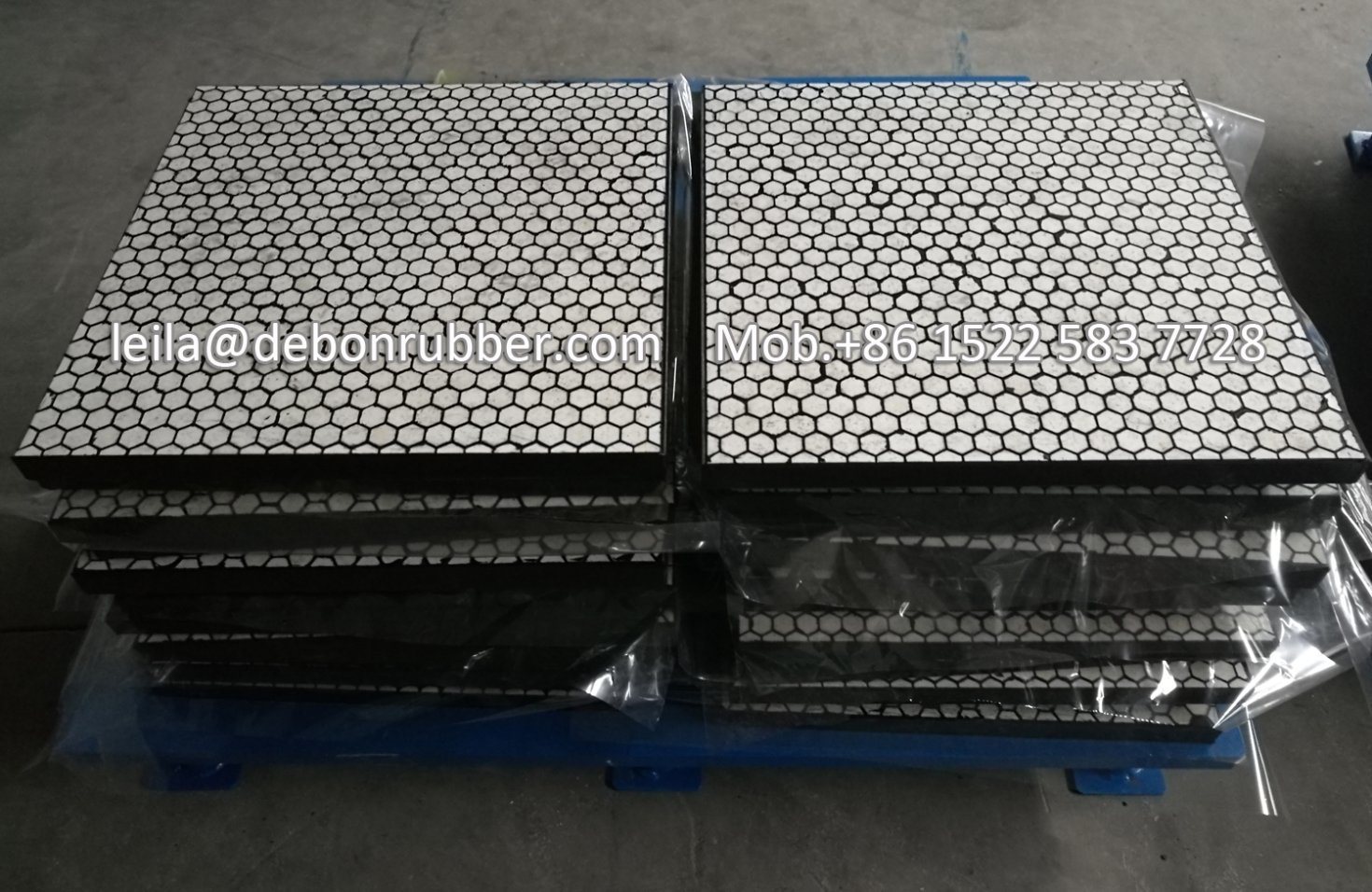

Specification (mm) | Thickness of ceramic (mm) | Thickness of rubber (mm) | Thickness of steel backing plate | Total thickness (mm) |

300x300x36 | Φ21x21 | 9 | 6 | 36 |

300x300x50 | Φ31x31 | 13 | 6 | 50 |

250x250x36 | Φ21x21 | 9 | 6 | 36 |

250x250x50 | Φ31x31 | 13 | 6 | 50 |

250x250x18(17.5x17.5x8) | 7 | 5 | 6 | 18 |

Special Dimendions and Shapes to order.

Abrasion resistant rubber alumina ceramic wear liner with ceramic cylinders, rubber ceramic wear panel

abrasion resistant rubber alumina ceramic liners on site:

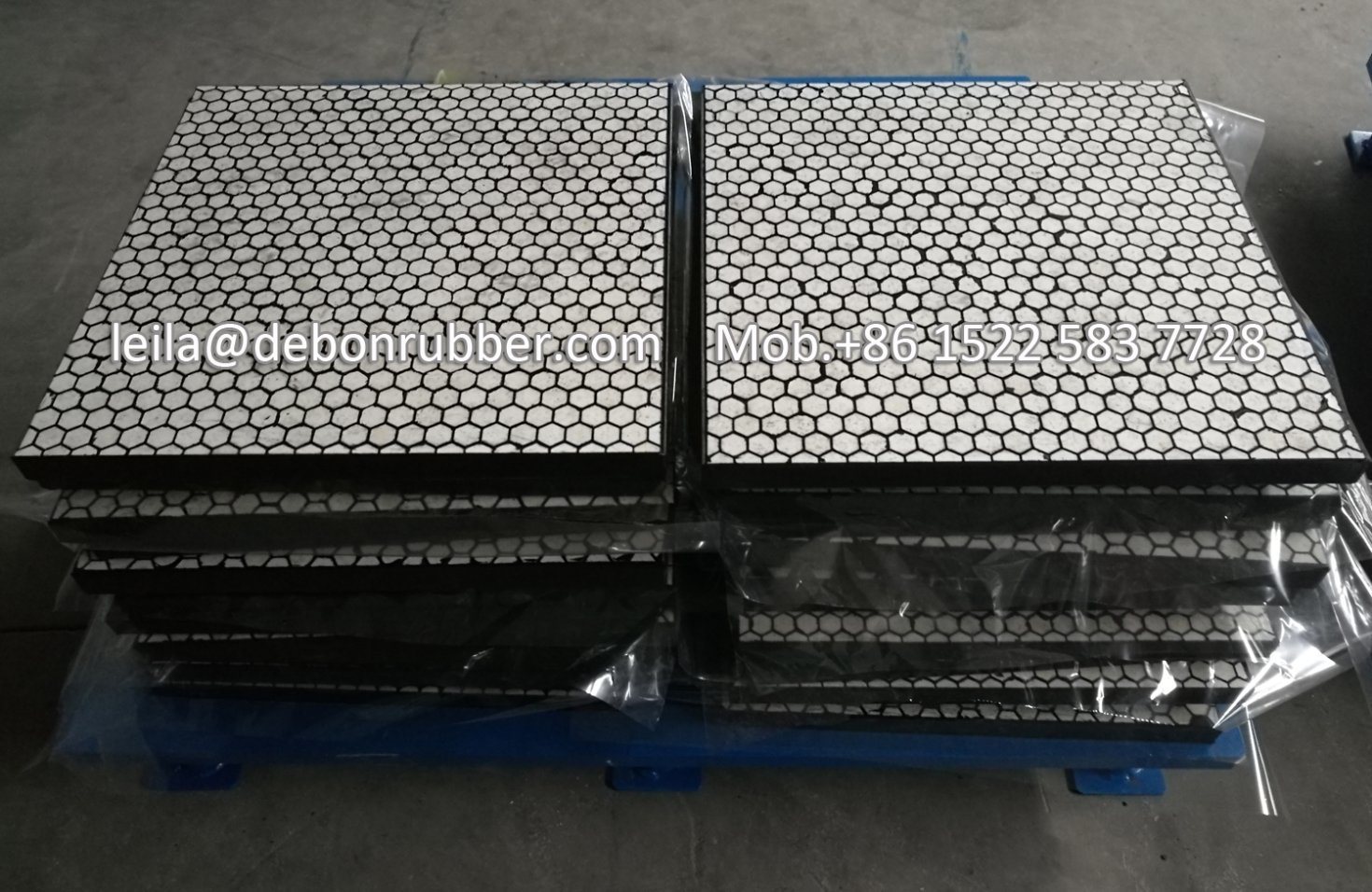

Company Introduction:

We are a manufacturer specialized in designing and manufacturing wear resistant products,ceramic liner, rubber lining, polyurethane lining , conveyor accessories, etc. Our products are widely used in bulk material handling industries including coal mine, steel plant, power generation, cement plant, metallurgy, chemical and other fields.

Export:

Our products have been exported to many countries: Australia, Chile, USA, Russia, UK, Indonesia, etc., good quality have be approved by our clients.

More information about abrasion resistant rubber alumina ceramic liners, send us inquiry please.

We welcome you to visit our factory all the time.