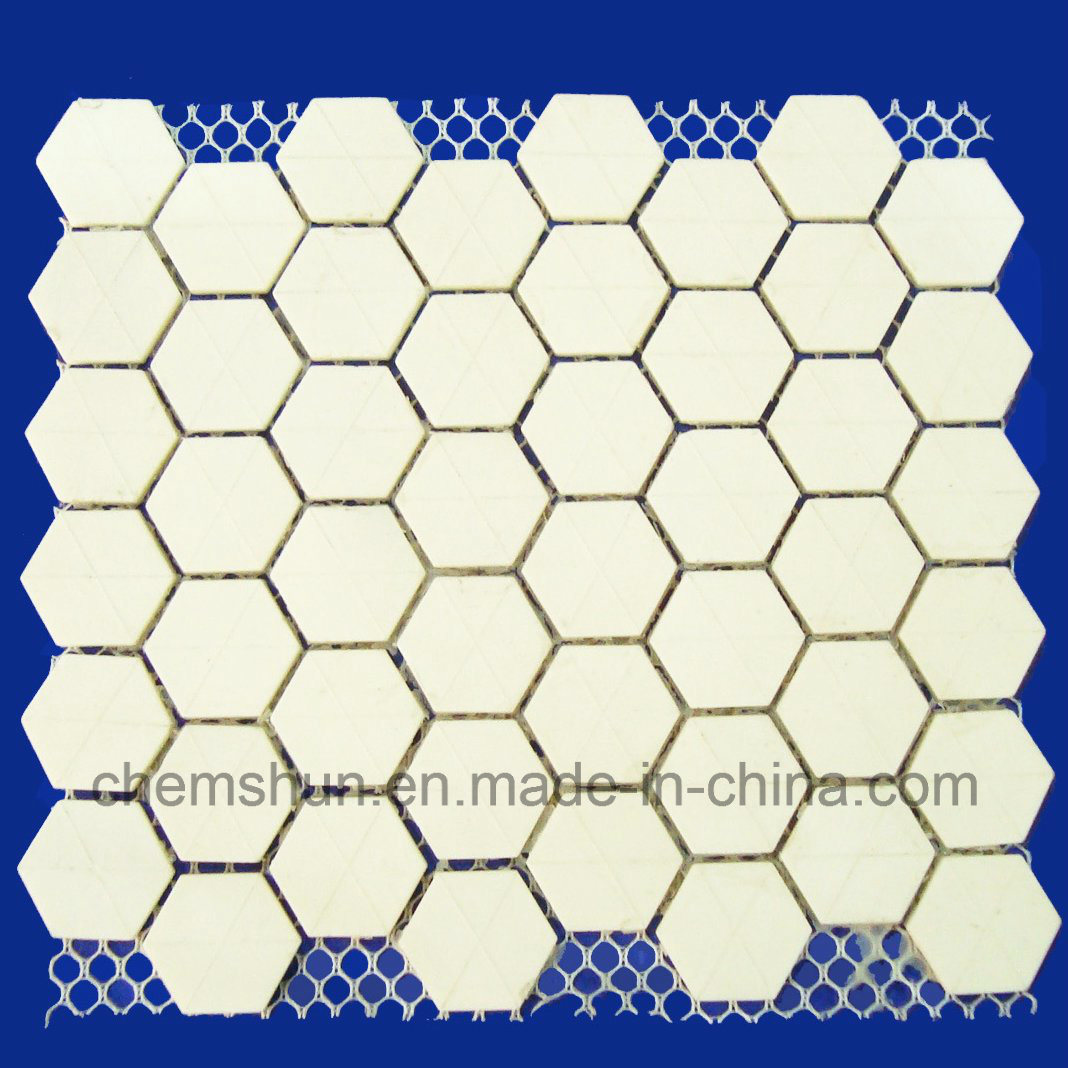

Wear Resistant Alumina Ceramic Hex Tile on Mesh

| Price: |

US $ 1000-2000/Ton |

| Trade Terms: |

FOB,CFR,CIF |

| Min Order: |

1/Ton |

| Pay Type: |

L/C,T/T,Western Union,Paypal,Money Gram |

Product Specifications

| Prod Model: |

chemshun ceramic hex tile |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Size Available: |

250*250mm, 300*300mm, 500*500mm |

| Alumina Content: |

92% or 95% |

| Density: |

3.6 and 3.7 |

| Mohs Hardness: |

9 Grade |

| Rockwell Hardness: |

More Than 87 Hra |

| Delivery Time: |

20days |

| Item Material For Ceramics Stick: |

Paper , Silk , Net |

| Application: |

Wear Resistant |

Product Description

Hex tiles mounted on strong synthetic fabric mesh.

high alumina ceramic tile mats

alumina ceramic hex on nylone net

hex ceramic mat

Wear resistant hexagonal tile

>>> Description :

Wear resistant ceramic hex tile mat also named ceramic lining pieces mats consist of small plate glued on acetate silk or other special medium. Alumina mosaic plate offer long wear life in .applications with sliding wear .the thickness and the low weight make these products ideal in applications where weight and space are limiting factors. Chemshun high alumina ceramic mosaics in a variety of sizes and shapes including square and hexagonal shapes . Dimensions range from 500*500mm ,300*300 mm, various plant components can be lined quickly and easily with these mosaic plate .

>>> Product character :

--- High hardness with Moh's hardness 9 grade

----High abrasion and chemical resistance

----Easy installation by epoxy resin glue water

----Easy mending if someone hex tile drop off

---- Various of alumina ceramic hex sheet size available

>>> Chemshun ceramic tile and sheet size

| square tile size | Hexagon tile sizes

| Ceramic square mat (stick on silk /nylon net/paper) size |

| 17.5*17.5 mm | S 6*T3~6 mm | 300*300 mm |

| 19.95*19.95mm | S 12 * T 3~25 mm | 200*200 mm |

| 30*30 mm | S 19.05 * T 3~25 mm | 150x150mm |

| 20*20 mm | | 500*500 mm |

| 25*25*4mm | | |

| | | |

| Note: more customized size available | |

Chemical Composition:

| Al2O3 | SiO2 | CaO | MgO | Na2O |

| 92~93% | 3~6% | 1~1.6% | 0.2~0.8% | 0.1% |

Physical properties:

| Specific gravity (g/cc) | >3.60 |

| Apparent porosity (%) | 0 |

| Flexural Strength (20ºC, Mpa) | 280 |

| Compressive strength (20ºC, Mpa) | 850 |

| Rockwell hardness (HRA) | 80 |

| Vickers hardness (hv) | 1050 |

| Moh's hardness (scale) | ≥9 |

| Thermal Expansion (20-800ºC, x10-6/ºC) | 8 |

| Crystal Size (μm) | 1.3~3.0 |

Pingxiang Chemshun ceramics Co., Ltd is a manufacturer of 95% & 92% Al2O3 alumina and ZTA (Zirconia toughness Alumina) wear resistant ceramic liner products. Chemshun ceramics was established in 2002, we have 15 years of professional ceramic producing and import & exporting experierence. Chemshun have the products and service of: Design, produce, sell, as follows:

1) 95% Al2O3 Alumina, 92%Al2O3 alumina, ZTA, abrasion wear resistant ceramic liner / linings and high quality grinding beads and grinding balls.

Chemshun manufacturing wear resistance Ceramic liner including: Alumina ceramic plain tile, ceramic weldable plate, alumina pipe liner, ceramic blocks, abrasion resistant lining, lined pipe and fitting, ceramic linings, wear-resistance ceramic linings, chemshun pre-engineered equipment lined ceramics and paiting, custom designed alumina ceramic, hexagonal ceramics sheet, square ceramic lining pieces, ceramic liner, Ceramic Conveyor Pulley Lagging, ceramic tube and all kind of engineered ceramics, the finished equipment according to drawings. Ceramic Grinding balls, griding cylinders. Products used in the mineral, steel, power, port, cement, ceramic, glass etc industries, and was fixed on the equipment of chute, cyclone, cone, fan etc.

2)Catalyst support media /support covering materials (Inert ceramic balls, 99 alumina balls, all kind of ceramic/alumina rings) and all kinds of tower packings(Mat: Eramic/Plastic/Metallic), saddles, pall rings, flower rings, raschig rings, cascade mini rings etc) and ceramic honeycomb products.

Aim for servicing with the global maket, we established a new factory in 2008 which mainly supplys the high alumina wear resistant product and the high quality catalyst support media. In 2016year we establish a new producing line special for 99.5%Al2O3 and 99% Alumina balls.

Has strong research and production capability, with an annual production capacity of 5000 tons of wear-resistance product (grinding balls & lining bricks, alumina plate, alumina mosaic product), 1500m3 catatalyst support /covering materials (inert ceramic balls, 99alumina balls, ceramic honeycomb materials) and 1500m3 various chemical packing. We aim to serve clients from all over the world.