Product Specifications

| Prod Model: |

SJSZ80/156+65/30 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Glazed Tiles Width: |

1040mm |

| Glazed Tiles Thickness: |

1-3mm |

| Application: |

Roofing Tiles Outdoor |

| Extruder Model: |

Sj-80/156+65/30 |

| Extrusion Capacity: |

400kg/H |

| Installed Power: |

176kw |

| Extrusion Speed: |

0.3-5mm/Min |

| Raw Materia: |

PVC, ABS, Asa, PMMA etc |

| Main Electrical Parts: |

ABB, Omron, Rkc, Schneider, FUJI, Delix etc. |

| Guaranteed Time: |

12 Months |

| Product Type: |

PVC Board |

| Board Layers: |

Multilayer |

| Automation: |

Automatic |

| Computerized: |

Computerized |

| Certification: |

ISO9001:2008 |

Product Description

with UV coating pvc plastic glazing/glazed roof tiles production line consists of main extruders, T-die and calibrating downstream units, which can continuously extrude single layer pvc glazed tiles, pvc/pmma and pvc/asa composite multi-layer galzed tiles.

PART 1: Advantages and applicationscompared with other ordinary plastic tiles, this kind of composite glazed tiles have more beautiful appearance, better quality, strong durability, and some special features: such as fire retardant, impact capacity, anti-corrossion, anti-freeze, waterpfoof, weather resistance and color retention etc,

The glazed roofing tiles are wised in the garden-style factory, tourist scenic spots, pavillions, hotels, family building etc.

PART 2: Main Techinical Data:

Extruder model |

SJSZ80/156 + SJ65/30 |

Capacity |

350kg/h+50kg/h |

Sheet specifications |

Width: 720/880/1040mm

Wave pitch:160mm

Wave length:220mm

Wave height:30mm

Thickness:1-3mm |

Emboss rollers |

1400mm*Φ300mm |

T-die head |

JC-Times brand |

Corrugation forming machine max haul off power |

20KN |

Haul off speed |

0.3-5m/min |

Cutting machine |

Pneumatic saw cutting |

Stacker |

6m |

Ridge tiles forming machine |

With end cover, slope ridge for step roof, T ridge for step roof, top ridge for step roof |

Other accessory machines |

High speed mixer, plastic crusher, plastic pulverizer etc |

PART 3 DETAILED PICTURES:

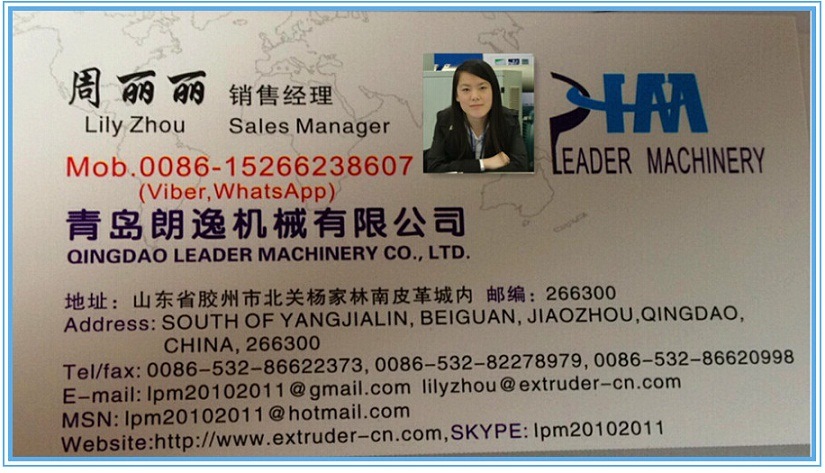

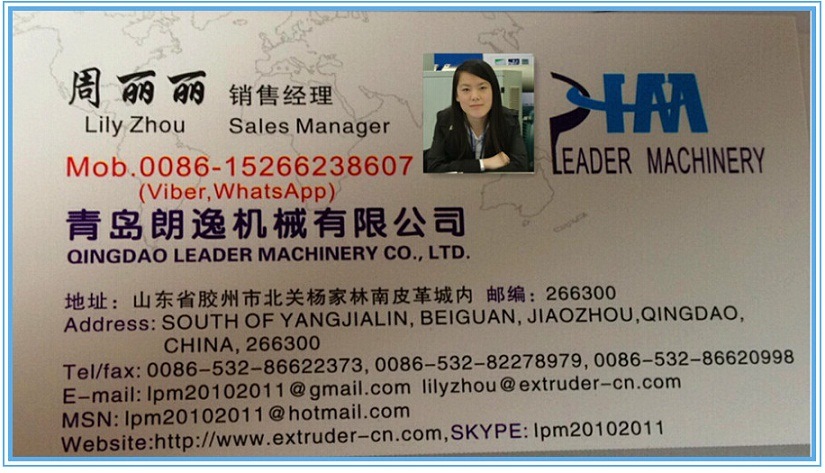

PART4 CONTACT INFORMATION:

Qingdao Leader Machinery Co., Ltd is an experienced and professional manufacturer of plastic extruder and extrusion lines for years. We can produce various equipments, including plastic sheet/plate extrusion lines etc. According to different requirement s of each customer, our engineers will provide most professional mechanical design and manufacturing, and the complete processing technology to meet their special application requirements.

Since foundation, we have been dedicated to study and research new products, new processing technology to satisfy the updating requirements of the world, and also we continuously digest and learn from the world advanced science technology and leading process. We are always standing firm ahead domestically in the plastic-extruder field as the pioneering representative. With years of experience in design and fabrication, we newly developed LM series extrusion lines, which realized the high efficiency extrusion idea "high precision control, high efficiency production, high quality production".

Through ISO9001-2008 quality certification, CE certification, SGS certification and GOST certification for Commonwealth of Independent States, strict following the standards of modern enterprise, the overall strengthening and the effective management of production, procurement, technology, and after sale service. We win the market by high quality products and services. At present, products have been exported to the US, Korea, Russia, Ukraine, Kazakhstan, Hungary, UAE, Turkey, Iran, Saudi Arabia, South Africa, Libya, Algeria, India, Nepal, Bangladesh, Mexico, Argentina, Chile and other countries and regions, praised by customers.