Product Specifications

| Surface Treatment: |

Wood Grain, Sanded, Brushed |

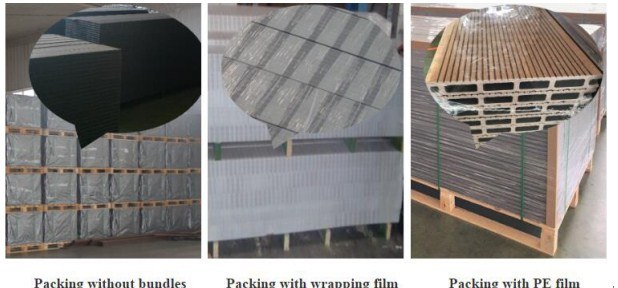

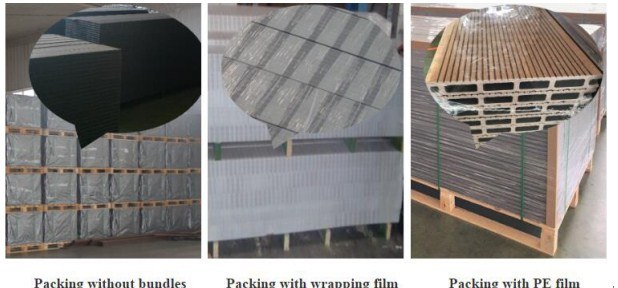

| Packing: |

PE Film + Wooden Pallet or According to Your Needs |

| Color: |

Grey |

| Certification: |

Ce, ISO, Fsc, ASTM |

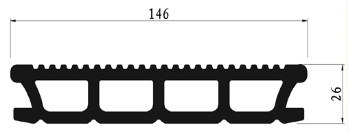

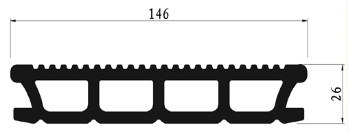

| Thickness: |

26 |

Product Description

Wood grain High strength Sustainable Wood plastic composite Decking/flooring (K26*146mm)

The advantages over Normal WPC:

The advantages over Normal WPC:| Items | Co-extruded WPC | Normal WPC |

| Color: | Rich, vivid,strong steady leveling natural wood color | Single solid color and the very few thickness oxidation |

| Anti-scratch | Stronger | Better than wood |

| Expansion rate | Lower,about 0.1% | About 0.3-0.5% |

| Water absorption | Smaller only the two ends | Better than wood |

| Weathering test | Much stronger | Better than wood |

| Water/oil stain | N/A | May occasionally occur |

| Cleaning Method | Water, very easy | Sand paper,steel wool etc |

| Wood grain | Never disappears | May be not very clear |

| Mold stain | N/A | Better than wood |

UV 2000 Testing and Evaluation Results: | Test Method | Test Item | Result |

| ISO 4892-2 | Xenon Arc Weathering | Non-exposure | 2000h Exposure |

| ISO 4892-2 | Color Change | - | Gray Scale 3 |

| ISO 178 | Flexural Strength

Flexural Modulus | 26.3Mpa

2.44Gpa | 25.0 Mpa, decrease 4.9%

2.24GPa,decrease 8.2% |

| ISO 179 | Impact Strength | 4.86KJ/square meter | 4.66KJ/square meter,decrease 4.1% |

ASTM Testing and Evaluation Results: | Test Method | Characters | Result |

| ASTM D638 | Tensile test | 18.0Mpa |

| ASTM E831 | Coefficient of linear thermal expansion | 40.5 μm/mC |

| ASTM D256 | Impact resistance | 33.7J/m Type of break: Complete Break |

| ASTM D6109 | Flexural strength | MOR:29.3Mpa

MOE:3715Mpa |

| ASTM D790 | Flexural properties | MOR:34.1Mpa

MOE:2503Mpa |

| ASTM D4060 | Abrasion resistance | Weight loss: 0.07g |

| ASTM D6007 | Formaldehyde test | ND² |

Colors available(can be customized):

Component:30% HDPE60% bamboo/wood fiber10% chemical additives ( antioxidant,colorants, coupling agent, stabilizers,blowing agents, reinforcing agents,lubricants,etc).Main feature:1) Water proof, Mildew proof, Anti-corrosion, Extreme durability2) High recyclable, eco-friendly, saving forest resources3) With the look of the natural wood but less timber problems4) Requires no painting, no glue, low maintenance.5) Available in various colors6) Easy to install and clean Applications:Garden,Fences & Rails,Courtyard, flower boxes,outdoor-flooring,dust bins,pavement, bridges,Wall-cladding,Pergola and Pavilion, Leisure/ landscaping places etc. Different Packages:

Component:30% HDPE60% bamboo/wood fiber10% chemical additives ( antioxidant,colorants, coupling agent, stabilizers,blowing agents, reinforcing agents,lubricants,etc).Main feature:1) Water proof, Mildew proof, Anti-corrosion, Extreme durability2) High recyclable, eco-friendly, saving forest resources3) With the look of the natural wood but less timber problems4) Requires no painting, no glue, low maintenance.5) Available in various colors6) Easy to install and clean Applications:Garden,Fences & Rails,Courtyard, flower boxes,outdoor-flooring,dust bins,pavement, bridges,Wall-cladding,Pergola and Pavilion, Leisure/ landscaping places etc. Different Packages: Customer annual demand:

Customer annual demand: | Country | Sales Quantity in 2017 |

| France | 1000sqm |

| America | 9000sqm |

| Brazil | 7000sqm |

| Canada | 6500sqm |

| Bulgaria | 5500sqm |

| Romania | 9800sqm |

| Thailand | 4900sqm |

| India | 8600sqm |

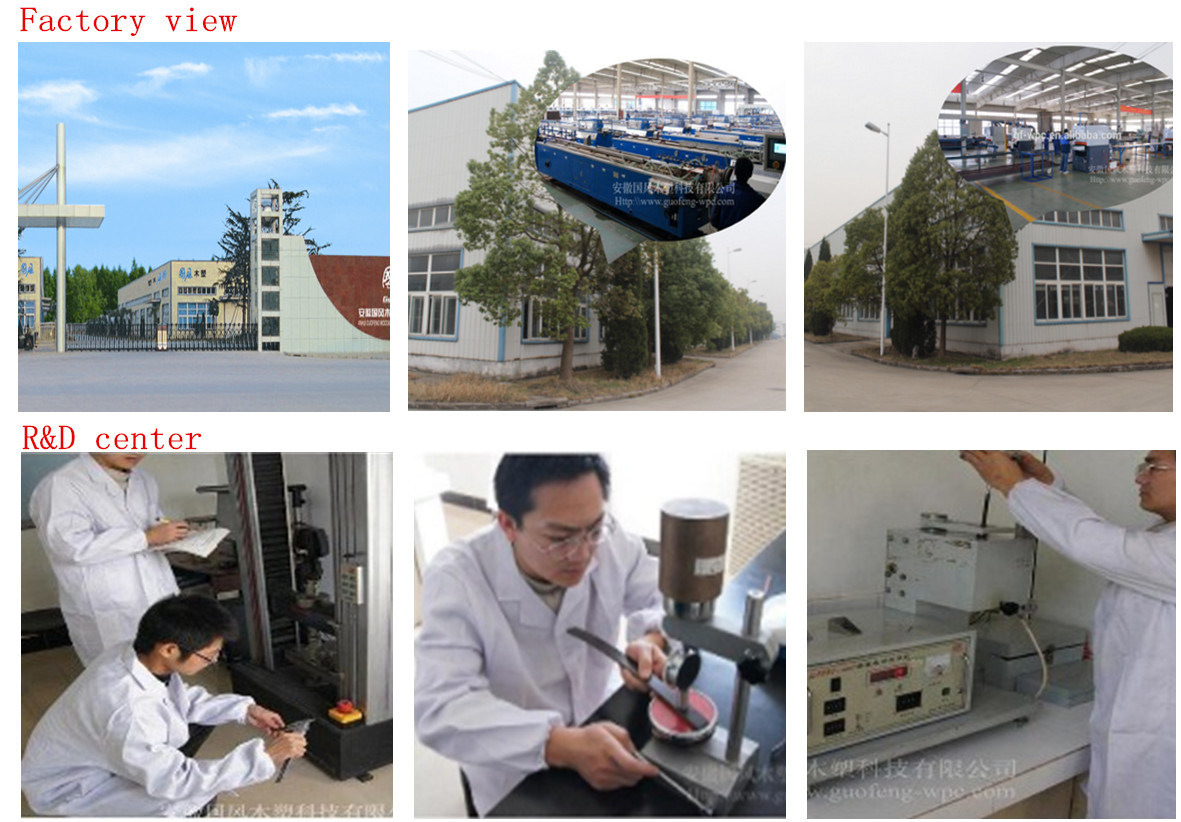

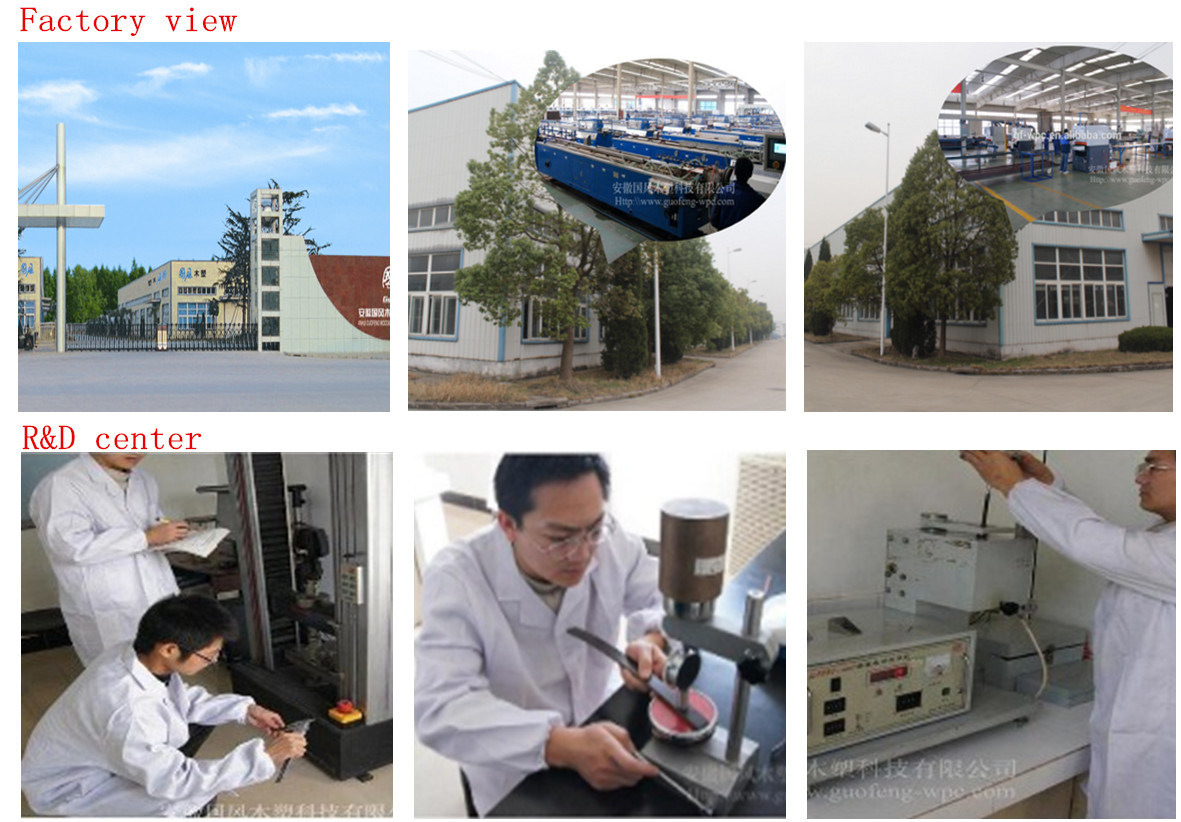

Factory image :

Certificates: FAQ1.Payment Method: 30% deposit and 70% before the shipment or against the B/L.100% L/C at sight.Any other method please kindly remind in advance,it can be negotiated.2.Delievery time: About 10 days after receiving the 30% deposit.3.MOQ 200sqm4.How to order: 1. if you are interested in WPC decking, let us know model, quantity, color you want to order.2. we will make a performa invoice for your order.3. we will deliver the produce ASAP when we receive your 30% deposit payment.4. Payment: T/T or L/C. we get 100% deposit, we will arrange the shipping.5. shipping: by sea, by air, by express... ect. EXW , FOB , CIF , CNF all available.6. production time: 10 workdays for 1x20GP order. 7. we will prepare documents for the customs clearence before container arrives.5.Guaranty: Limited 10 years, for details please check with document.6.How to Contact: Mary

FAQ1.Payment Method: 30% deposit and 70% before the shipment or against the B/L.100% L/C at sight.Any other method please kindly remind in advance,it can be negotiated.2.Delievery time: About 10 days after receiving the 30% deposit.3.MOQ 200sqm4.How to order: 1. if you are interested in WPC decking, let us know model, quantity, color you want to order.2. we will make a performa invoice for your order.3. we will deliver the produce ASAP when we receive your 30% deposit payment.4. Payment: T/T or L/C. we get 100% deposit, we will arrange the shipping.5. shipping: by sea, by air, by express... ect. EXW , FOB , CIF , CNF all available.6. production time: 10 workdays for 1x20GP order. 7. we will prepare documents for the customs clearence before container arrives.5.Guaranty: Limited 10 years, for details please check with document.6.How to Contact: Mary

Sales ManagerAnhui Guofeng Wood-Plastic Composite Co., Ltd.Mobile Phone: 0086-18726485325 Website:www.guofeng-wpc.com, www.cofinewood.com

* Subsidiary of Anhui Guofeng Plastic Industry Co., Ltd. Listing on Shenzhen Stock Exchange market. (000859)

*Established in March, 2004

*Registered capital: RMB70, 000, 000

*Located in Baohe industrial park, Hefei City.

*Covering about 200, 000 square meters.

*Normal worker: 130 Engineer: 18 QC: 14 Others: 30

*Possessing 7 domestic compounding systems and other 2 systems from Germany.

*Possessing 44 domestic extruding lines and other 5 lines from Austria.

*The only one WPC factory using Europe whole set auto-production lines in China.

*The TTL production capacity is about more than 2, 500, 000 sqm per year.

*Have formed core technologies by self and owned 40 patents.

*Presided and formulated the first domestic WPC standard QB/T4161-2011H

*Passed ISO9001, ISO14001, CE, FSC and ICS.

*Having testing reports for UV, Anti-slip, ASTM, fire-proof etc by Intertek and SGS.

*Ever be the one of WPC suppliers for 2008 Olympic Games, 2010 Shanghai EXPO, 2011 Xi'an Horticultural EXPO and 2012 London Olympic Games and 2016 Rio Olympic Games.

*Exported to Europe, North and South America, Africa, Asia and other regions.