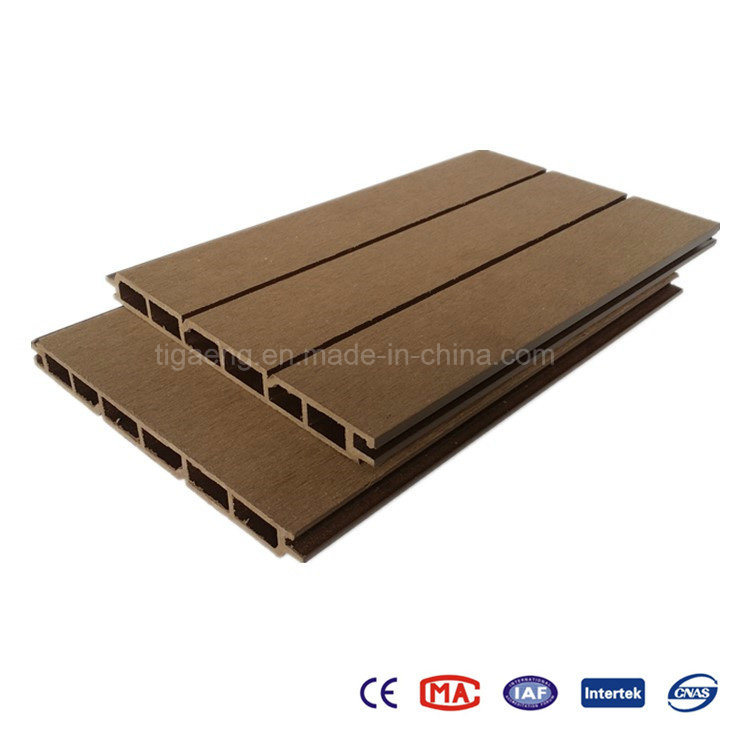

Wood Plastic Composite Wall Cladding/Outerior WPC Wall Decorative Panel

| Price: |

US $ 8-12/Square Meter |

| Min Order: |

100/Square Meter |

| Pay Type: |

L/C,T/T,Western Union,Paypal,Money Gram |

Product Specifications

| Prod Model: |

TIGA-WLWPC063 |

| Thickness Range: |

8-50mm |

| Width: |

25-60mm |

| Length: |

10-11800mm |

| HS Code: |

39189090 |

| Color Type: |

as Per Request of Customers |

| Material: |

Wood + HDPE +Additives |

| Surface: |

Sanded, Brushed or Embossed |

| Warranty: |

10 Years |

| Usage Type: |

Outdoor, Swimming, Garden, Park, Yard, Balcony |

| Technique: |

Extrusion |

| Thickness: |

8-40mm |

Product Description

TIGA WPC Wall Cladding Boards are perfect for any commercial, domestic, new build or refurbishment cladding project as a colour-stable alternative to traditional timber cladding.

Made from a combination of recycled wood and plastic, composite cladding gives a contemporary looking low maintenance option that will dramatically change the look of any building.

WPC Composite Wall Cladding Advantages:

1.With high density,high strength and good looking

2.Non absorbent,effectively prevent the decay and damage

3.Advocating environmental protection,back to nature

4.Creating beautiful and comfortable land

5.Anti-corrosion,anti-crack,anti-deformation

6.Easy to install and clean

Full Name | Wpc Wall Cladding/Wood Plastic Composite Wall Decoration |

WPC Component | 55% Wood Fiber 30% HDPE Plastic 15% Non-Hazardous Chemical Additives |

Size | Regular WPC Wall Cladding Size:166.5mm*22mm, 200mm*20mm |

Length | 2250mm, 2300mm, 2900mm, 3600mm, 5800mm Will make full use of containers' space |

Color | Regular wpc cladding color: Teak, Red, Brown, Chocolate, Grey, Black Our Technicians will adjust any color you want |

Surface Treatment | Sanding, Brushing, Embossing, wood grain |

Warranty | Guarantee 15 Years, Lifetime 25 Years |

Certifications | INTERTEK/ASTM, CE, SGS, ISO, ENGTEST, CN TEST, JP TEST |

Application | Wall Cladding, Outerior Decoration |

Installation of WPC Wall Panel:

Tools Required

You can use woodworking machinery for cutting, sawing, drilling and so on.

Bases Requirements

1. Walls should be solid, stable, smooth and level. High points must be removed and low points filled with filler.

Do not install on hollow or uneven areas.

2. Screws must be galvanized or stainless steel to resist corrosion or rust for external application, and it is recommended to be long enough to penetrate joist (wood substrate) at least 1-1/2

Preparations:

Wall | Screw Specification(mm) |

Concrete wall | 50X6mm expansion bolt |

Steel wall | 50X6mm self-tapping screw |

Wooden wall | 50X6mm self-tapping screw |

Installation Process

1. Before installing the wall panel onto the concrete wall or brick wall, it needs to install the joist onto the wall firstly.

( The aluminum alloy or steel frame or small wood bar as the joist is also okay ).

Sometimes, the WPC wall panel can also be installed onto the wall directly according to the permission of architect. And the steel/wooden wall can be installed the WPC wall panel directly.

2. Fixing the wall panel onto the joist one by one with screw or clip.

Other WPC products:

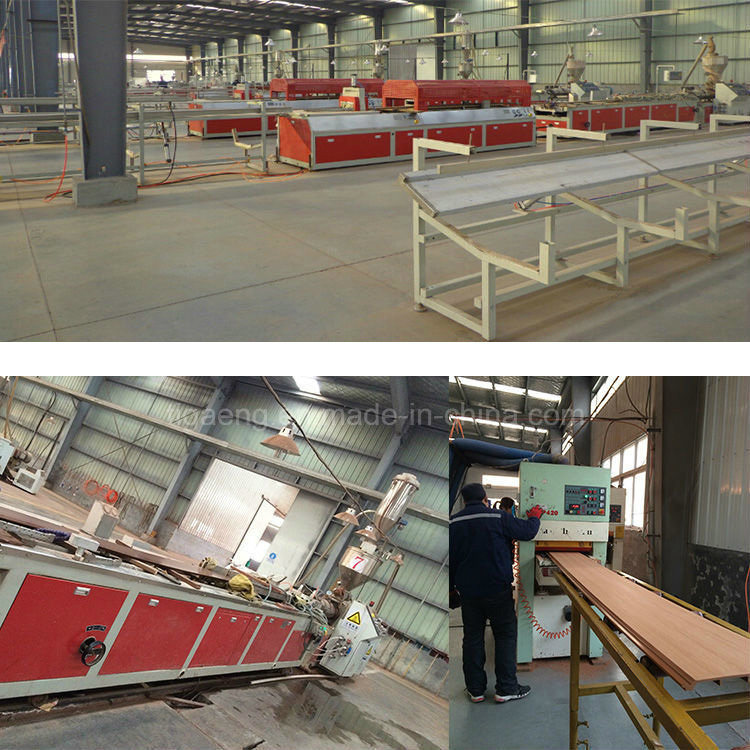

Quality Control

Quality is our top priority. We know that WPC products are usually used in large-scale projects so any quality issue can have devastating effect on our clients' finance and reputation. TIGA will not allow this to happen. From controlling wood powder particle size; analysing plastic liquidity to compression tests. We are doing everything we can to ensure our products are of top quality.

Coordinated Teams

TIGA is not just a factory. We have a professional R&D team and an experience trading team. They alway work together to provide the best solution for our clients. Our trading team is constantly bringing back feedbacks from our customers to help our R&D team further improve our existing products whilst our R&D team experiments on a daily basis to create new features for WPC.

Tiga Group, as a member of the House Structure Association, branch of China Steel Structure Association and other associations, is one of the most powerful enterprises of steel structure and temporary building projects in Henan Province and in China. Tiga Group is an ISO 9001: 2000 registered enterprises and is appraised as AAA grade credit enterprise by Construction Bank of China, Qingdao Branch. Tiga Group has passed the approval of CE and SGS

Tiga Group is a high tech enterprise and is headquartered in Zhengzhou High Tech Development Zone. Tiga Group is a comprehensive enterprise of design, producing and installation. Now the group has three branches: Tiga Building Facility Company Limited, Tiga Steel Structure Company Limited, and Tiga Modular House Factory.

Tiga Group has leading R & D capabilities and technology advantages, and its products such as steel structure series, modular house series, and light steel sandwich panels series and roofing sheeting series are widely used in industry, traffic, city construction, commercial and other temporary accommodation. With the advanced technology, full products range, excellent sales and service teams, Tiga's products are sold throughout the home and abroad markets. Tiga Group is a supplier of the series products for the country's key projects, such as the Olympic Sailing Center, bay bridge of Jiaozhou Gulf, Qingdao cross sea tunnel, etc. Tiga Group has the right of import and export, and its products have been exported to over 110 countires, such as, the UAE, Saudi Arabia, Oman, Angola, Equatorial Guinea, Libya, France, Poland, Romania, Russia, Australia, the Philippines, Indonesia...etc.

Tiga Group is dedicated to the developing the resource saving, environment protection products to enhance urban civilization and improve the living conditions. Through the incessant revolution in construction field, the new steel structure industry may achieve product standardization, modularization, universalization. Insisting on the maximization of customers' interest, Tiga Group's objective is to be the leader in the steel structure and temporary building field with the high quality products, and professional, efficient service.