Product Specifications

| Prod Model: |

TS-01(150x25mm) |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Size: |

150X25mm |

| Surface: |

Brush Surface, Sanding Surface |

| Product: |

WPC Material, Water Proof Material |

| Formula: |

50% Wood Fiber, 38% Plastic, 12% Additives |

| Lifetime: |

25~30years |

| Length: |

2.2m/PC, 2.7m/PC, 5.4m/PC |

| Production: |

15days /20ft Container |

| Resistance: |

High Impact Resistant |

| Environment: |

Environment Friendly |

| Environmental Protection: |

100% Recyclable |

| Environmental Protection Grade: |

E0 |

| Function: |

Anti-Static |

| Expansion Rate Of Water Absorption: |

<2.5% |

| Usage: |

Public |

| Pattern: |

Grooved, Sanded, Embossing |

| Surface Finish: |

Grooved, Sanded, Embossing |

| Classification: |

Wood-Plastic Composite |

| Solid Wood Composite Floor: |

Wood-Plastic Composite |

| Surface Material Of Solid Wood Composite Floor: |

Poplar |

| Certificates: |

CE |

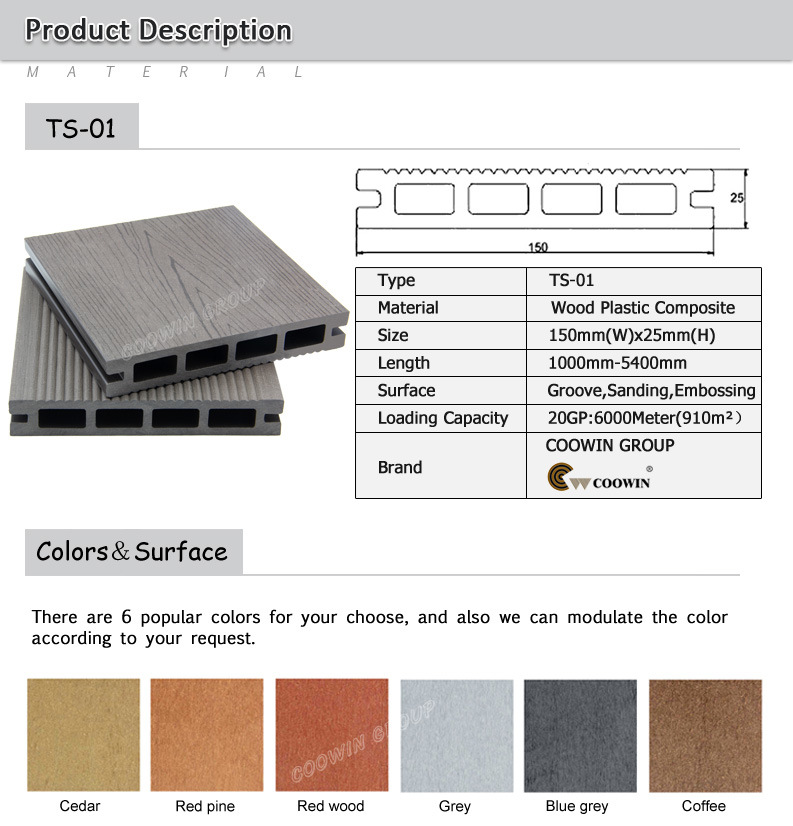

Product Description

BAREFOOT WOOD MAKE YOUR WORLD SMILE

Name WPC decking floor for garden(TS-01)

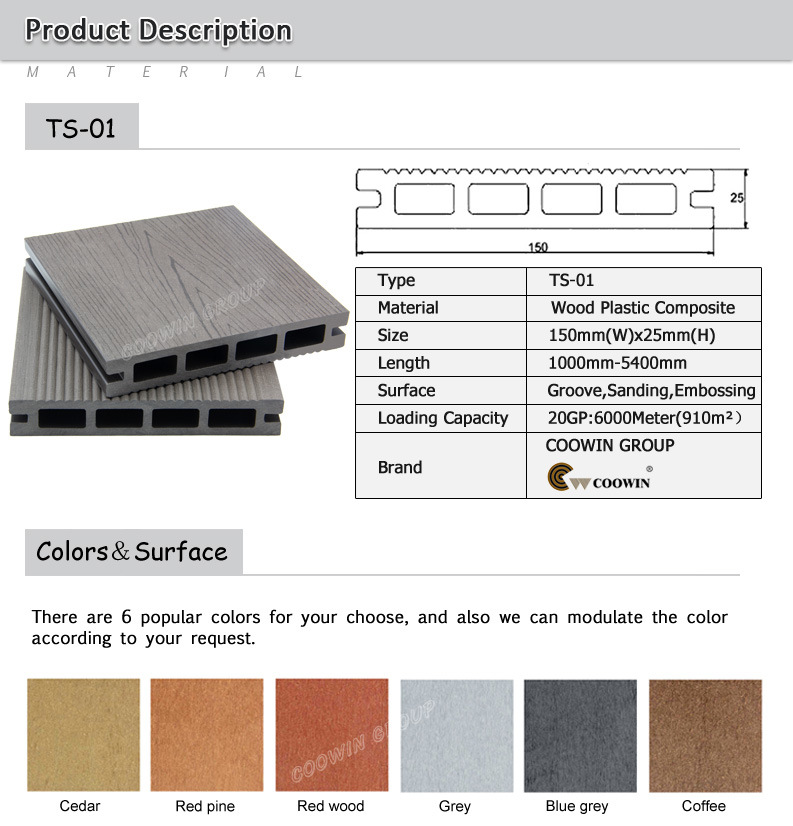

Color Brown, cedar, grey, red pine, coffee, nature wood etc.

Material 50% wood fiber

35%~40% plastic (Grade A Recycled HDPE)

10%~15% Chemical additives ( Anti-UV agent, Anti-oxidation agent etc. )

Surface treating method Brushed, grooved, sanded, embossing

Applications office, hotels, public buildings, superstores, architectural fascias, commercial premises

Benefits traditional wood appearance, low maintenance, long lifespan, no splintering, no mold, environment-friendly, 100%recycle

Exported Countries Europe, Asian, South America, Middle East, Australia, Africa

Quality authentication CE Certificate

ISO 9001: 2000

Size Width X Thickness:

150 X 25MM

Length: 5.4M/PC, or customized

Packing Pallet

Delivery TimeOne 20 foot container per week

1. About us

We are a company specializing in WPC( Wood plastic composite) products for almost 10 years, have a mature formula, complete and strict quality control system. Owing CE certificate, have exported to Europe, Asia, America, Australia, Middle East, Africa.

2. About Product

BAREFOOT WOOD Wood-Plastic Composite (WPC) siding is manufactured from a combination of plastic, natural fiber and some additives using special equipments. It mixes natural fiber and plastic perfectly to keep the natural impression of wood but with rich colors of plastic. It has gradually replaced wood and plastic, getting widely used in more and more fields.

3...Advantages:

1. Green ecological, Innovative technology, Lifestyle

2. Elegant nature wood grain texture and touch, with wood scent

3. Elegant and detailed shape design

4. Resistant to cracking and splitting

5. Anti-water and moisture, acid, alkali and pest resistance

6. Environmental friendly and no other hazard chemical

7. Safe to use for many years

8. Low maintenance and Never needs painting, but also can be painted

9. Carpenter oriented and friendly easy installation and Quick to install saving on labor costs

10. Structural product available

11. UV resistance, Fade resistant, Durable

12. Dimension stability against moisture and temperature

| Characteristic | WPC | Wood |

| Using property | Resistance to moisture | Waterproof | Not waterproof |

| Resistance to rot | Antisepsis | Easy to rot |

| Resistance to split | Never split generally | Split at the effect of weathering |

| Resistance to distortion | Infrequent to distort | Easy to distort, especially outdoor |

| Application to outdoors | Null | Very adaptive | A few genus of treated-wood is adaptive |

| Maintenance | Painting | Not need paint | Need paint periodically to maintain |

| Coloring | Not need paint, many choices | Need paint sometimes |

| Lifespan | Null | Not less than 25-30 years | Exist with maintained |

| Form | Null | Can be extruded to manufacture many types of forms | Form is simplex |

| Environment effects | Null | Be recycled 100% | Consume woods |

| Summing up | Null | The ratio of capability to price is large | The ratio of capability to price is lesser |

BAREFOOT WOOD MAKE YOUR WORLD SMILE

BAREFOOT WOOD MAKE YOUR WORLD SMILE